Today, we honor the strength, resilience, and achievements of women everywhere.

A special recognition goes to the dynamic community of Women in Plastics (WiP) Italy - a thriving association of women making waves in the plastics industry. Together, they are breaking barriers, fostering innovation, and paving the way for a more diverse, inclusive, and sustainable future 💚

Women in Plastics represents a powerful collective of professionals dedicated to being a voice for the female perspective in the industry. By uniting their talents and expertise, they are creating a vital platform to inspire and drive meaningful change.

Here’s to celebrating women, empowering progress, and building a better tomorrow 🌍

Integrity is more than keeping promises - it is about delivering on them with precision, transparency, and accountability. Whether we are designing a custom foam extrusion line, advising a client on the right solution, setting realistic delivery timelines, or even acknowledging when we don’t have an immediate answer, we act with honesty and fairness. We believe that truth builds trust, and trust is the foundation of long-term success.

Integrity begins within. At FAP, we cultivate a culture of respect, inclusion, and ethical responsibility. We foster open communication and a sense of ownership, empowering our people to make responsible decisions. By aligning our actions with our values, we create a workplace where collaboration thrives.

At FAP, integrity is not just a word - it is how we work, communicate, and grow together. It is the force that binds us to our clients, our team, and our partners. In a world where trust is scarce, we choose to stand firm in our principles, proving that ethical business is not just possible - it’s the only way forward.

To find it out, we have to consider: administrative costs; production costs; warehouse costs.

In this article, we will consider production costs, specifically those costs necessary to produce final products from expanded polyethylene (EPE) and polypropylene (EPP) foam.

1. Raw materials (usually represent 45-55% of the total cost of finished products)

2. Logistics (warehouse and storage)

3. Energy costs

4. Work productivity indicator

The polyethylene (EPE) and polypropylene (EPP) foam processing sector is slowing down; some, even speak of oversaturation of the offer. To overcome this problem, manufacturers have often chosen to act on quality by: reducing product density, reducing nominal thickness, choosing low-cost raw materials. This strategy has enabled them to survive in the short run but cannot be considered a solution.

A key factor in the overall calculation of production costs for expanded materials such as polyethylene foam (EPE) and polypropylene foam (EPP) is the choice of equipment and process technology.

Using low-cost technology may seem convenient, until we quantify how much it costs a company to produce 1 sqm of defective product.

In order to provide a technological advantage in production, FAP engineers design our lines with 4 fundamental characteristics:

Equipped exclusively with independent gravimetric dosing units with a dosing accuracy of 0.3%, for the best control of the recipe (for checking the cost of raw materials per unit of product). The station is able to guarantee the change of any component during the production process in 7 minutes max. (for the minimization of production waste).

Reducing production waste allows reducing inventories, increase stock turnover and obtain cost-effective batches, thus reducing product storage costs.

The twin-screw counter-rotating FAP foam technology significantly reduces:

- the risks of foam shrinkage due to the disruption of its cellular structure;

- bubbles on the foam material due to thinning of the cell walls;

- excessive gas expansion.

This eliminates the risk of products "overproduction", which would also affect their storage costs.

The cost of energy is rising: in many countries, in recent years, it has doubled. It is evident that this item has a great influence on production costs. This is why FAP complies with the highest and strictest energy efficiency standards by designing with specific attention:

- the heating elements: FAP extruders are shorter and more compact than single-screw extruders and consume 25-30% less electricity to heat the cylinder;

- the main motor: ABB's unique SynRM jet-rotor motors with energy class IE5 provide high specific power and torque and low winding and bearing temperatures, thus reducing energy consumption by 25-30% compared to standard induction motors;

- the gearbox: the modern Zambello ZT3 gearbox guarantees a high transmitted torque density (up to 17 Nm/cm3 per shaft).

FAP foam extrusion lines are some of the most efficient in terms of energy consumption per unit of production and provide huge cost savings.

Industrial automation processes are more important today than ever before: production lines must be intuitive in order to simplify the training of operators and quickly train new ones, but they must also be able to independently (automatically) perform numerous technological tasks.

By minimizing the number of operations on the line performed directly by operators, it is possible to significantly increase labor productivity in production, thus positively influencing the cost of finished products.

At FAP, listening is more than hearing words - it’s about truly understanding the unspoken needs and expectations. This philosophy shapes the way we approach every project, driving innovation and creating lasting partnerships built on trust and collaboration.

At FAP, listening is more than a value - it’s a philosophy that drives us forward. By putting this into practice, we not only meet expectations but exceed them, helping our clients succeed in a competitive global market.

In the calendar that FAP distributed for Christmas, flexibility is defined as a mindset that characterizes the way each member of the team approaches their work.

“We are quick to adapt to changes and respond to the needs of the context,” says Karina, the company’s Marketing Manager. “For us, being flexible means listening to the requests of clients and partners and finding customized solutions that meet their needs, while maintaining the agility necessary to compete in an evolving market. Internally, we promote an open mindset, encouraging our team to be versatile in their activities and to respond promptly to new challenges. Client needs can change rapidly, and being flexible is not just an added value - it’s an absolute necessity.”

FAP has made flexibility one of the cornerstones of its business strategy, demonstrating that adapting to specific client requests creates real value. The ability to customize machinery to meet production requirements allows the company to be a partner in efficiency and optimization.

Here, our 'technical' icon of flexibility transforms into a small work of art.

Flexibility is a tangible promise that FAP delivers on every day. Through this philosophy, the company not only meets its clients’ needs but helps them grow and thrive in an increasingly demanding global market.

Each value is accompanied by a dedicated illustration, crafted to represent its essence. These distinctive icons, designed in true "FAP style", highlight various thematic areas and are integrated into our institutional communications. You’ll find these icons in our official materials, such as when you visit us in October at the K2025 Trade Fair in Düsseldorf, Germany.

Yet, technology is also about creativity, and imagining is the first step toward innovation. Our “technical” icons transform into small works of art, capable of conveying the same concepts in an imaginative and evocative way. You’ll find this artistic version of our values on our social media platforms and, of course, here in the news section of our website.

This journey is not just a way to tell our story, but also an opportunity to inspire, demonstrating how technology and imagination can work in harmony to innovate and shape the future.

Stay tuned to discover, month by month, the values that make FAP a unique and visionary partner.

Now, as we step into 2025, we invite you to join us on a new path - one that goes beyond technology and machines.

In a fast-paced world overflowing with things that often lack true meaning, we choose to focus on what truly matters. In 2025, we will share our core values that define who we are and guide everything we do - integrity, transparency, collaboration, listening, flexibility and so much more.

But this is not just about us. It’s about what we aim to bring to the table: REAL VALUE. We don’t just build machines; we build trust, relationships, and impactful solutions. Every project we take on is an opportunity to create something meaningful and lasting.

Throughout the year, we’ll be sharing stories and insights that reflect these values. We hope they inspire you as much as they drive us to improve, innovate, and support our partners in building a brighter future.

From all of us at FAP, we wish you a 2025 filled with purpose, success, and meaningful connections. Let’s shape this year together, making every moment count.

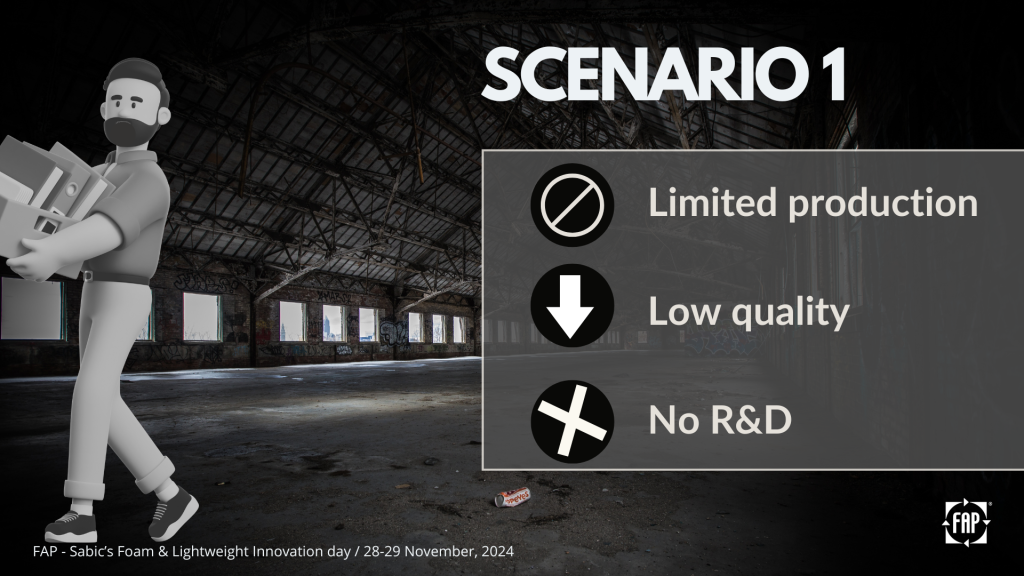

In today's rapidly evolving industrial landscape, businesses are under increasing pressure to invest in innovative technologies to meet market demands. At the recent SABIC Conference, we had the honor to present insights on how machine design is transforming the foam industry to meet pressing market demands like sustainability, cost efficiency, and product innovation.

However, companies face significant hurdles, including higher labor costs, volatile raw material prices, and fluctuating energy costs, all of which squeeze profit margins. At FAP, we embrace these challenges head-on, focusing on how extrusion machinery is evolving to meet the demands of today and tomorrow. Let’s dive into the world of polymer foams, the challenges they present, and the cutting-edge solutions we’ve developed.

Polymer foams have been indispensable in various applications for years, from acoustic and thermal insulation to food packaging. Imagine enjoying authentic Italian gelato stored in an XPS foamed container - an everyday example of how foams enhance quality of life. These versatile materials are made primarily from polymers like PP, PE, and PS, using physical expansion (with CO2) or chemical expansion methods to achieve their unique properties.

The global push toward sustainability demands recyclable products. While physical foaming offers this advantage, chemical foaming renders products non-recyclable. The market already favors recyclable solutions, and soon, clear labeling will classify products as "green" (recyclable) or "red" (non-recyclable).

But the journey to sustainability isn't without challenges. Incorporating recycled materials into production introduces variability in material properties, leading to uneven density, foam collapse, and increased waste. Dispersion of recycled granules and gases within the melt remains a critical hurdle.

Market pressures often lead clients to ask: “Can you lower your price per square meter?” With labor costs fixed, the focus shifts to reducing material and operating costs. Traditional extrusion processes lack precise energy monitoring, and inefficiencies during startup or material change increase expenses.

At FAP, we are dreamers - and our mission is to turn dreams into reality. Our innovative extrusion technologies empower companies to achieve their goals by addressing these challenges with tailored solutions.

For those who choose the second path, FAP offers groundbreaking solutions.

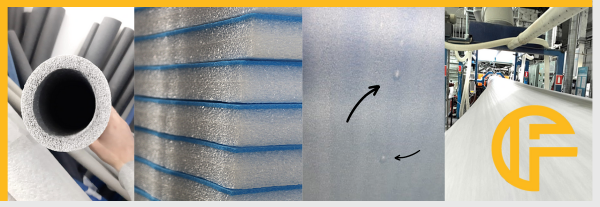

Our twin-screw counter-rotating extruders redefine material homogenization. The counterrotation creates dual mechanical shear stresses, ensuring uniform dispersion of additives and gas. This process enhances foam cell formation, delivering products with superior physical properties.

By applying high pressure to molten polymers, we increase gas solubility, achieving recyclable foams with exceptional thermal stability, compressive strength, and low density. These properties rival those of traditionally non-recyclable, chemically foamed products.

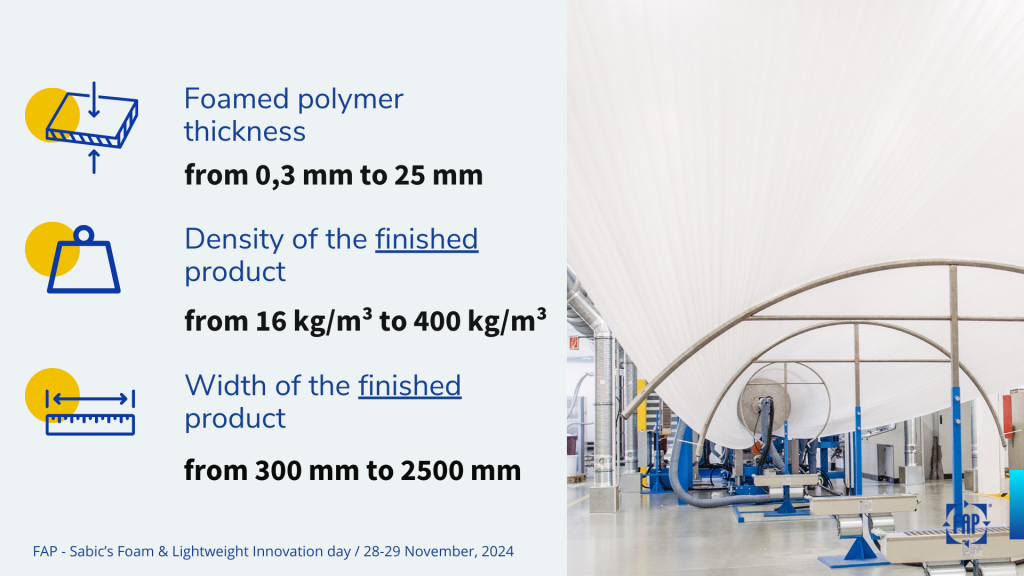

Flexibility is key in today’s market. FAP technology enables clients to produce foam thicknesses ranging from 0.3 mm to 25 mm using the same machine. Additionally, our extruders support diverse polymer compositions (e.g., PP+EVA, LDPE+MLLDPE), offering unparalleled adaptability to market demands.

Our commitment to innovation is embodied in the Italian Foam Centre for Research & Innovation, where we explore new materials and optimize processes to push the boundaries of foam technology.

Packaging is critical in foam production, ensuring product quality during transport. In the 1990s, we revolutionized the process with our Soft Winder system, which:

This innovation has cut raw material costs by 6% per square meter, delivering both quality and cost-efficiency.

For foam thicknesses above 8 mm, we have achieved the use of 100% recycled PIR material without any virgin resin. Our clients integrate up to 30% PCR content using highly selected and filtered scraps, further advancing sustainability.

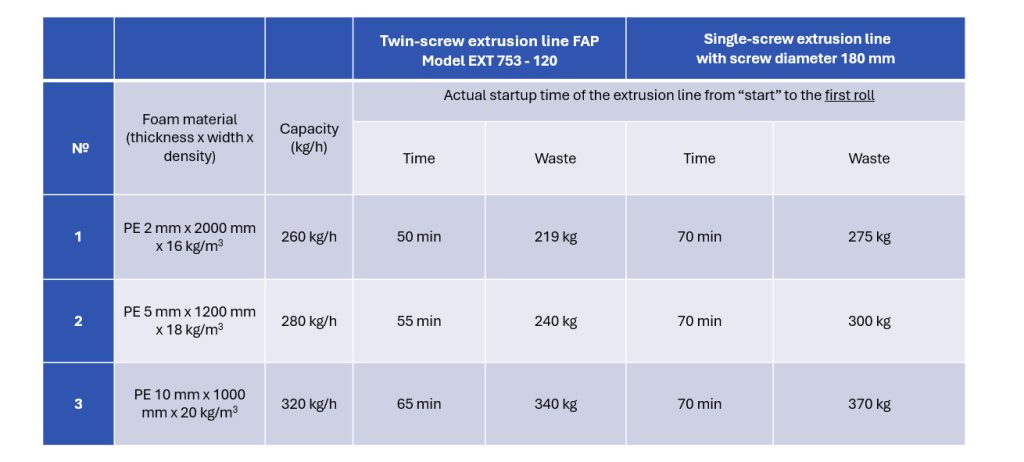

Our "smart" cooling systems and advanced thermoregulation reduce startup times by up to 60 minutes and process waste by 30%, saving up to € 400 per startup. Pressure control across screw sections enhances energy efficiency, lowering energy consumption by 44% compared to traditional systems.

At FAP, we don’t see problems - only challenges waiting for solutions. Our commitment to innovation ensures that what once seemed like a dream becomes reality. From 100% recyclable foams to cost-effective, high-performance machinery, we are transforming the foam industry.

If you share our vision for a sustainable, productive future, let’s start a partnership. Together, we can turn dreams into reality.

Contact us or visit our R&D center to discover how FAP can empower your business.

Extruded polystyrene (EPS) foam is today the main and cheapest type of foam polymer from which most single-use food containers and trays, coffee cups and egg containers are made.

So why are there more and more companies choosing the production of expanded polypropylene (EPP) in recent years? There are many debates, discussions and articles on this topic, and in some countries the use of extruded polystyrene foam in food packaging is already completely prohibited by law or is going to be soon.

Modern technologies make possible to recycle and reuse both polypropylene and polystyrene, but there is always a "BUT".

And here are some of notes about the properties of EPS foams:

The use of recycled polystyrene, as opposed to recycled polypropylene, is much more limited. Recycled polypropylene can be used in many industries, from injection molding to polypropylene filament production with varying percentages depending on the industry.

EPS foam is significantly inferior to EPP foam in terms of resistance to high temperatures. Thus, disposable tableware made of EPP foam can be used at temperatures up to 120-130 °C, and tableware made of EPS foam cannot be used at temperatures above 80-90 °C.

If we look at the statistics of the total volume of plastic waste recycling, polystyrene recycling takes up on average 9% of the total volume of recycled waste of this type of raw material, and the share of polypropylene recycling in the total volume of its disposal to landfill is on average 17%.

In addition, due to the more costly sorting process, more expensive logistics to recycling centers and the peculiarities of processing this type of waste, more and more factories are refusing to process expanded polystyrene.

This is pushing governments around the world to ban the use of extruded polystyrene in the food industry. Even though it is a single use, food container in EPP is not going to be banned and it will be a valid and safe alternative and totally recyclable solution worlwide.

Our ITALIAN FOAM CENTRE, together with polyolefin manufacturers and partners, is working to find opportunities and give new and improved physical and mechanical characteristics to polypropylene foam, making this product even more environmentally friendly and accessible to the market.