- Company

- Machinery

- Services

- ITALIAN FOAM CENTRE

- News

- Contacts

close

- Company

- Machinery

- Services

- ITALIAN FOAM CENTRE

- News

- Contacts

Discover Our Custom Plastic Cutting and Welding Solutions because We have the technology and expertise to bring your project to life.

At FAP, we specialize in providing top-notch machinery for cutting and welding plastic materials, tailored to meet the unique needs of our clients. With our extensive range of equipment and expertise, we offer a diverse array of solutions to suit various projects and applications.

Cutting Machines:

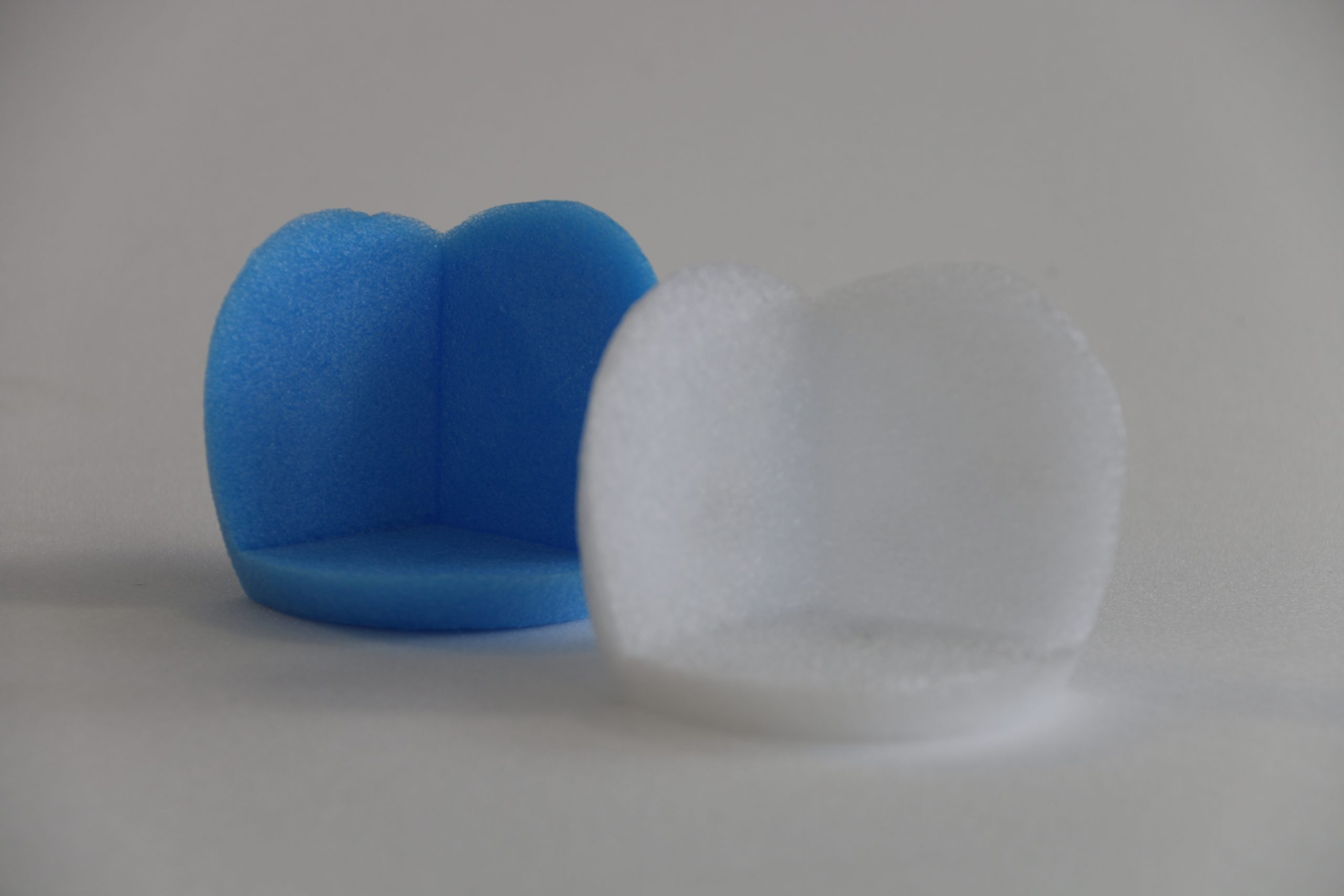

Our cutting machines for foam, bubble film, laminated materials of different densities and thicknesses are engineered to deliver unparalleled accuracy and efficiency.

Welding Systems:

Our welding systems are designed to ensure the production of robust bags of various dimensions. We have the capabilities to weld materials of different characteristics as foam and bubble air films also laminated with precision and reliability. Our welding machines are equipped with cutting-edge technology to ensure consistent results.

Tailored Solutions for Your Projects:

At FAP, we understand that every project is unique. That's why we offer personalized solutions tailored to your specific requirements. Our team of experts will work closely with you to analyze your project needs and recommend the most suitable cutting and welding solutions. Whether you need standard equipment or custom-designed machinery, we have the capabilities to deliver solutions that exceed your expectations.

Experience the Difference:

With years of experience in the industry, we have built a reputation for excellence in providing high-quality cutting and welding solutions. Our commitment to reliability, and customer satisfaction sets us apart as a trusted partner for businesses across various sectors.

Get in Touch:

Ready to take your plastic cutting and welding projects to the next level? Contact us today to learn more about our customized solutions and how we can support your business needs. Let us be your partner in success.

Experience the difference with FAP.