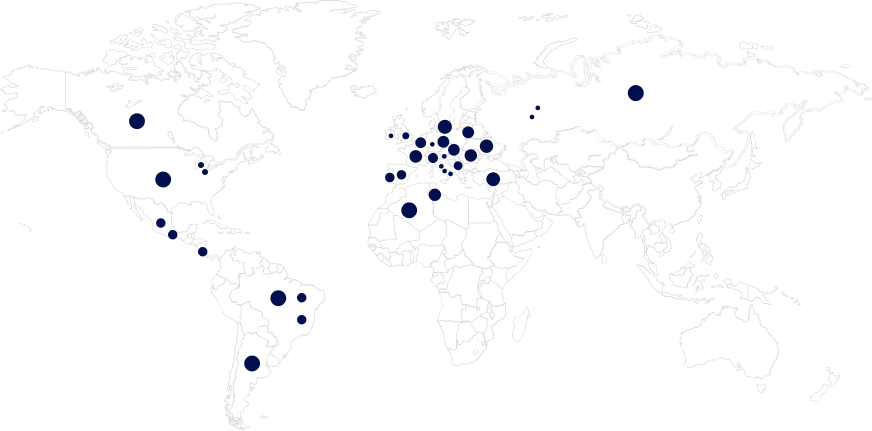

In un’azienda che progetta e costruisce macchinari industriali, la sostenibilità non è un concetto astratto. È una responsabilità concreta: progettare soluzioni che consumano meno, durano di più e permettono ai clienti di lavorare con maggiore efficienza e sicurezza - oggi e negli anni a venire. Per FAP, sostenibilità significa fare bene il nostro lavoro, ogni […]

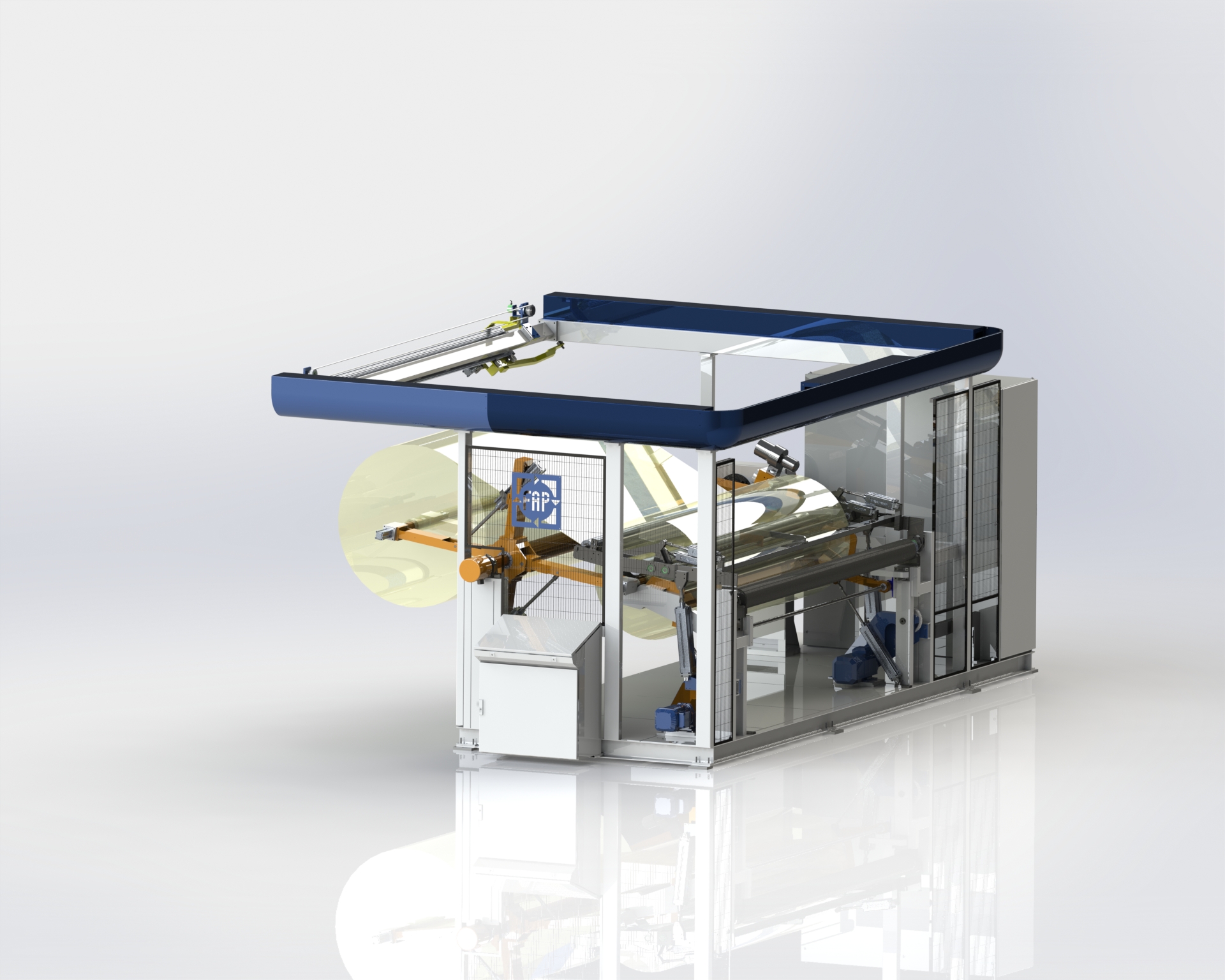

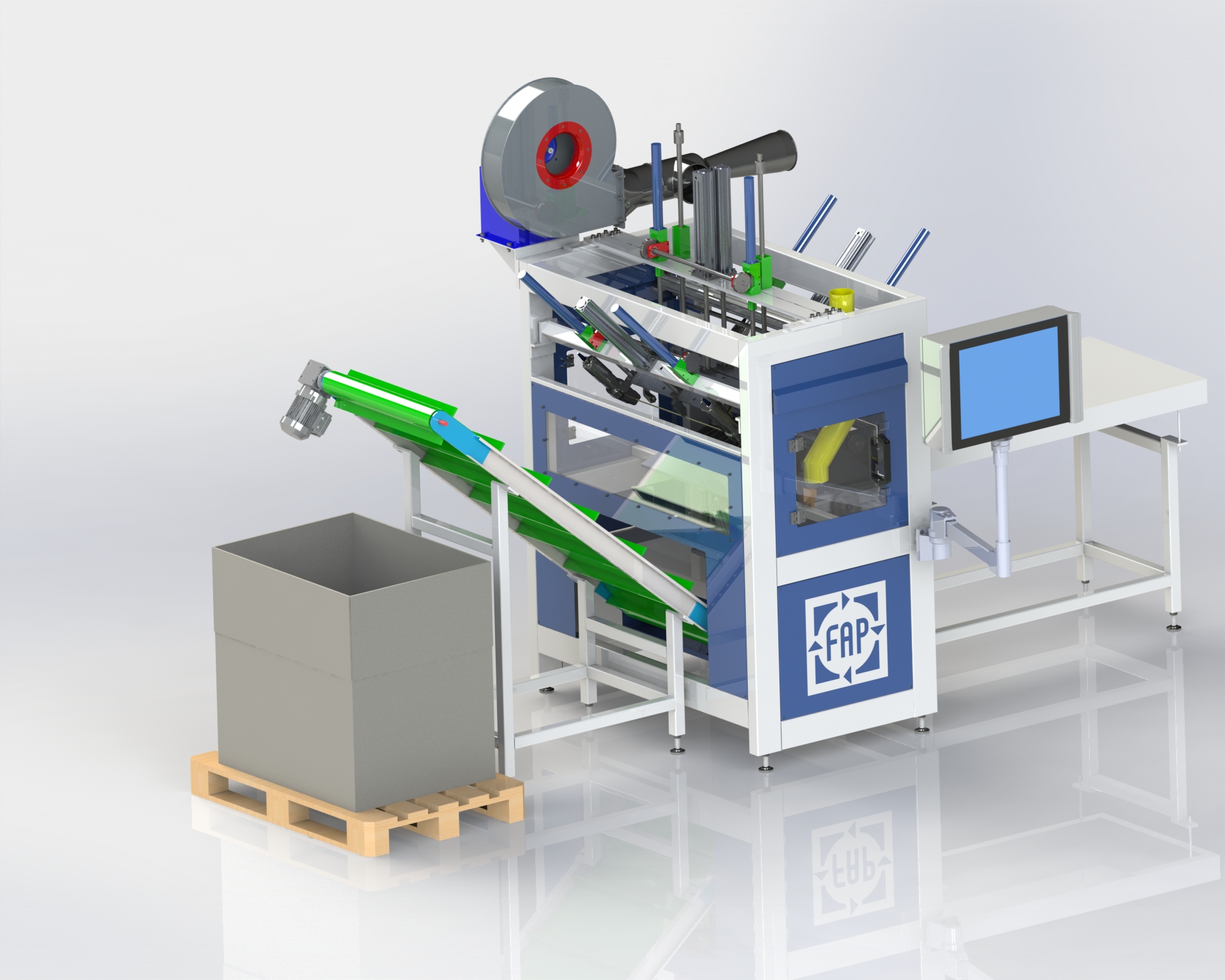

Tecnologie innovative e

all'avanguardia

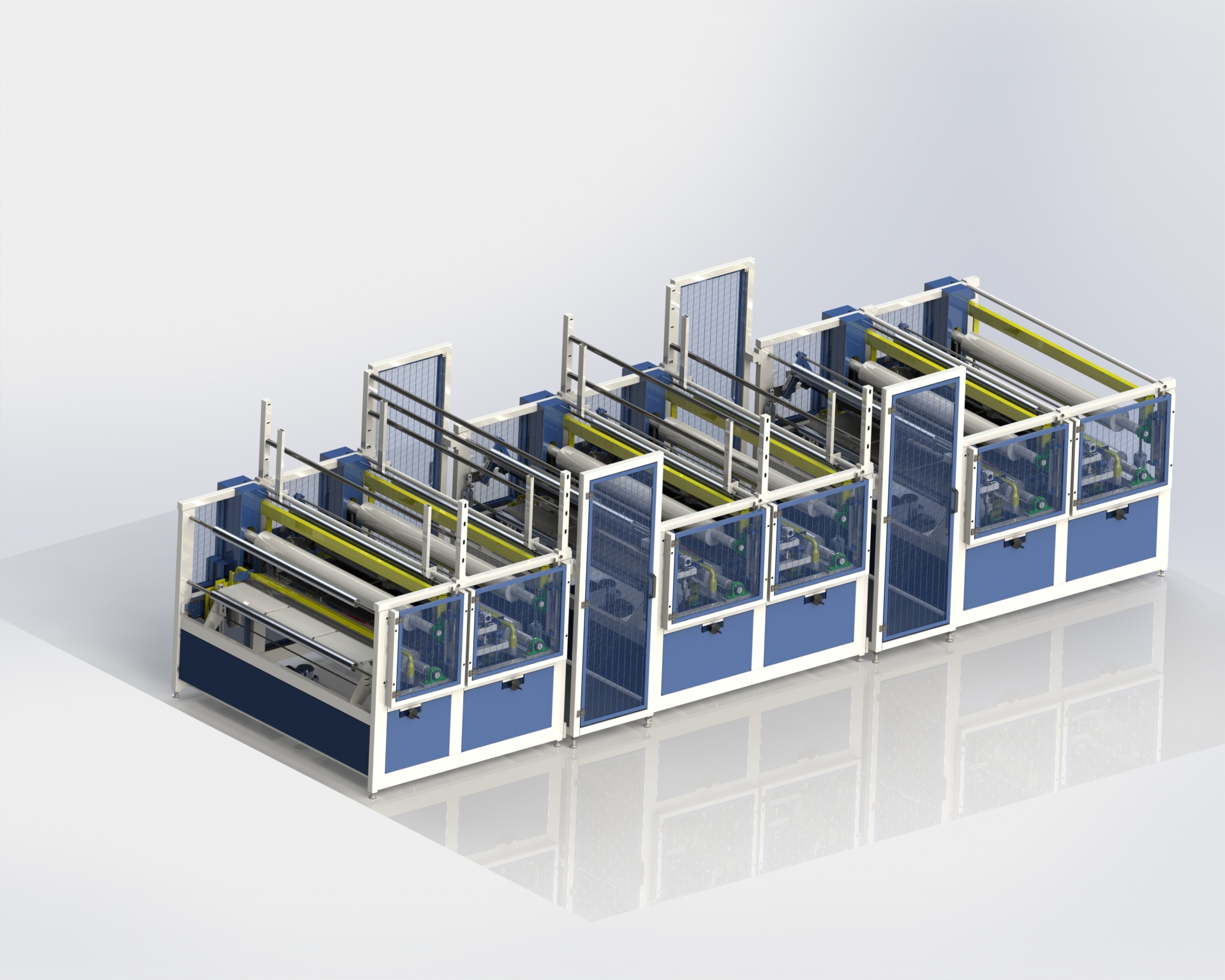

Performance e produttività eccezionale -

qualità del film espanso

inimitabile

qualità del film espanso

inimitabile

Tecnologie innovative e all'avanguardia

Performance e produttività eccezionale - qualità del film espanso inimitabile