- Company

- Machinery

- Services

- ITALIAN FOAM CENTRE

- News

- Contacts

close

- Company

- Machinery

- Services

- ITALIAN FOAM CENTRE

- News

- Contacts

From October 8 to 15, we’ll be in Düsseldorf at K2025, the world’s leading plastics and rubber trade fair.

You’ll find us at Hall 16 / Booth 16D68 – and we’d love to meet you.

At K2025, FAP will present the best tailored solutions:

Each project reflects our way of working: listening first, designing custom solutions with care, and building long-term partnerships. Every machine is unique - and so is every conversation that shapes it.

But this year, there’s more than just technical solutions.

Inside our booth, we’re creating something unexpected and emotional.

It’s not about automation or technical features. It’s about what makes us human.

At FAP, we believe that our values are the real roots of everything we do. Each month of this year, we highlight one core value - Listening, Integrity, Efficiency, Innovation - and show how it drives our daily work, from engineering to after-sales service.

At K2025, we’ll celebrate these principles with a dedicated Values Corner – a space to pause, reflect, and reconnect with what matters most.

Because in today’s world, where automation, high-speed production, and streamlined processes dominate, we need to remember what keeps companies and people grounded.

Like the roots of a tree, values are invisible but essential: they support growth, give direction, and connect us to something meaningful - even as everything around us accelerates.

With more than 3,000 exhibitors at K2025, it’s easy to get lost in the noise of machines and innovation.

That’s why we invite you to slow down and meet us.

Not just to explore high-performance foam extrusion technology for example, but to have a real, valuable conversation.

Let’s talk about your production challenges, your goals, and how we can support you create your next big success - with technology that fits your process, and a team that’s here for you.

Because your project deserves more than a standard solution.

It deserves our expertise - and our attention.

📍 We’re already scheduling meetings for K2025.

If you’d like to reserve a time slot, get in touch with us.

We’ll be there.

Will you?

We believe that innovation only has value when it generates Real Impact.

Our Research and Development is driven by a clear goal: to make our Machines Smarter, more Efficient, and Ready to face the challenges of modern production.

From materials to mechanics, from automation to user experience, every improvement is the result of Listening, Analysis, and Creativity.

Together, we explore new possibilities, identify shifts in the market, and develop ideas that turn into solutions.

We are often invited to industry events to share how the power of collaboration leads to progress.

This shared vision turns technical challenges into opportunities, and every project into a path for learning and growth.

Suppliers, clients, collaborators, and partners - all contribute to driving us forward.

At FAP, innovation is also a mindset.

We encourage every team member to question the status quo, experiment with new approaches, and keep learning.

From engineering to after-sales, every department is invited to bring ideas to the table.

Innovation: The Seventh Pillar of FAP’s Identity

In previous months, we introduced four other core values of our daily approach:

Flexibility, our ability to adapt to the needs of each project and each client.

Listening, the attention we give to those who work with us and rely on us.

Integrity, the transparency and consistency that guide our words and actions.

Efficiency, Getting things done with clarity, speed, and purpose.

Reliability, How we build, how we respond, and how we follow through.

Collaboration, We believe in co-creating value.

Looking for a partner who will understand your needs and turn your ideas into a high-performance solution?

Because when people work together, unique solutions - and lasting results - are born.

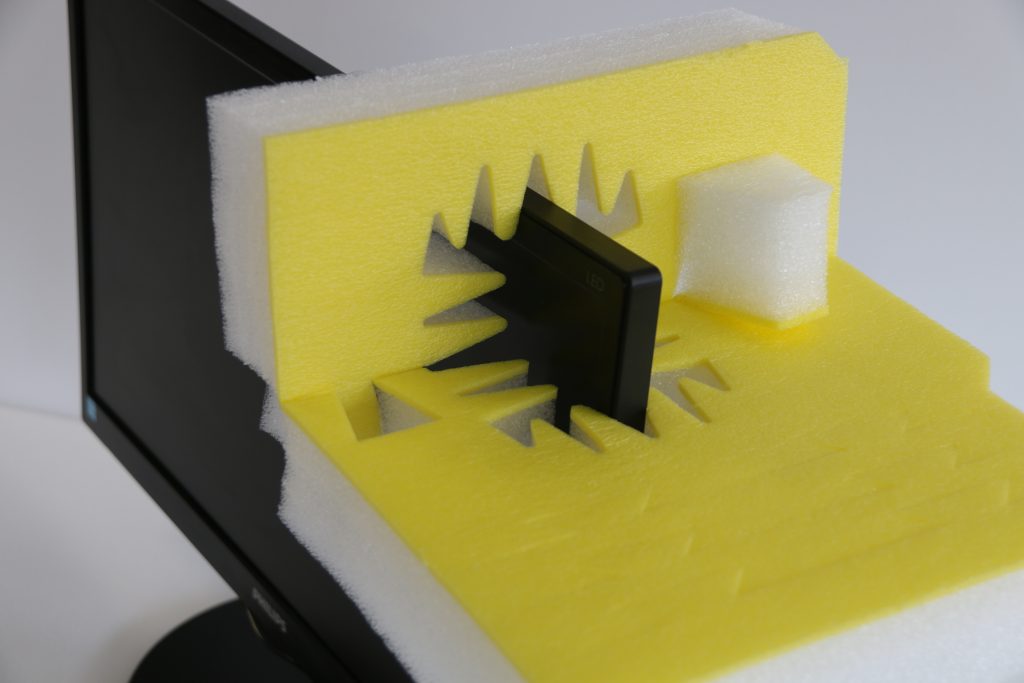

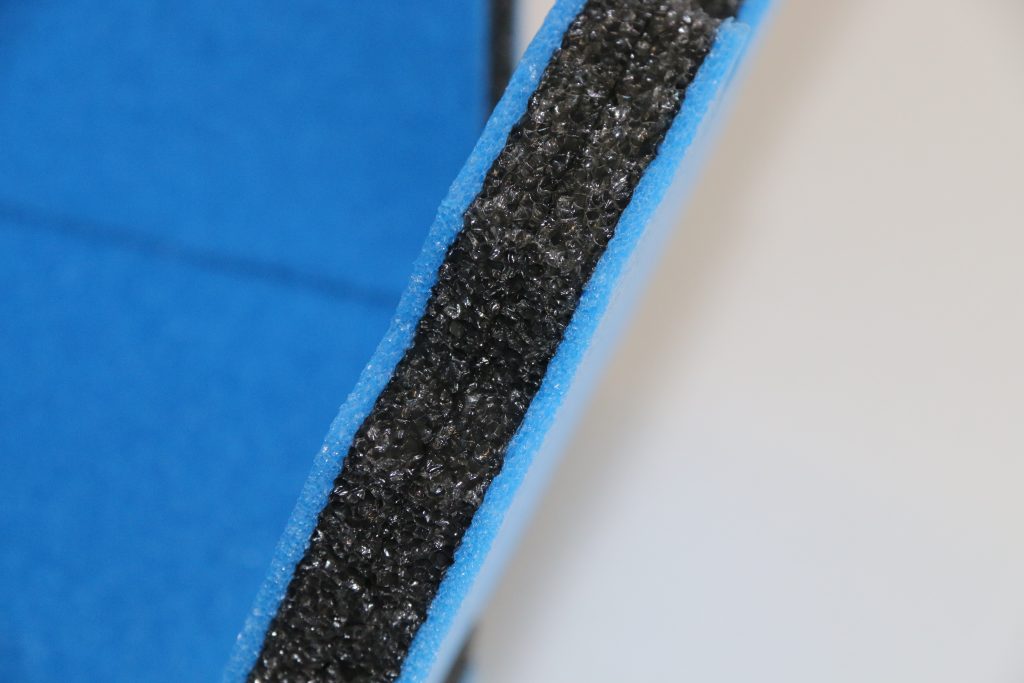

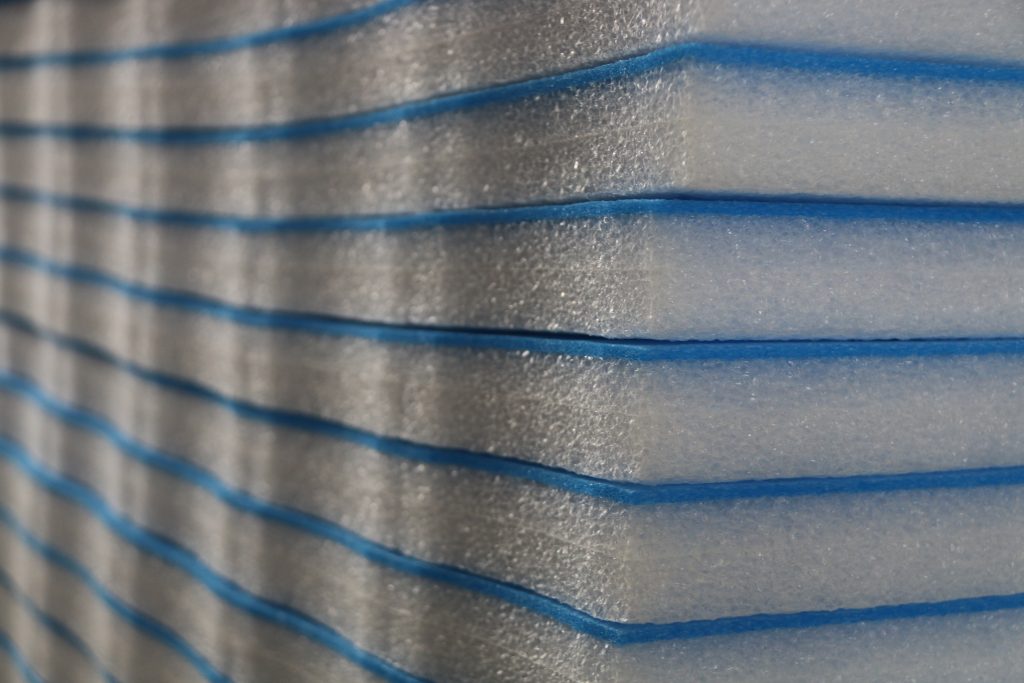

At FAP, we understand that the extrusion of gas-filled polymers is a critical process requiring precision and the right equipment. However, the lamination of physically foamed materials is equally important. This process involves bonding foamed polymers either to themselves (to increase thickness) or to other materials like reflective foil, PET, and HDPE, enhancing the final product's physical and mechanical properties. Our Laminator models has been specifically developed to ensure optimal lamination results, guaranteeing both flexibility and high performance in this delicate phase.

Though lamination might seem simple, it has many nuances that can affect the final product's quality, productivity, workplace safety, and production costs. What technical features of the equipment can be both an advantage and a significant drawback? Here’s what manufacturers and / or "converters" should consider when selecting equipment for laminating physically foamed polymers and bubble wrap:

For nearly four decades, FAP’s closed-cell foam polymer lamination technology has been trusted in Europe, North, and South America. Continuous improvement by our team of engineers and technologists, combined with a deep understanding of critical processes like "degassing" of physically foamed polymers and adhesion changes under complex esters and antistatic agents, allows us to create unique and high-quality lamination lines.

At FAP, when you walk through our doors, you don’t just find machines - you find people working together. Engineers and technicians, sales teams, suppliers, and clients, partners. Because collaboration isn’t just a phase in our workflow - it is our workflow.

In a world of manufacturing, true innovation happens through collaboration. For us, it means building side by side - understanding every perspective, every expertise, and turning shared knowledge into cutting-edge, custom-built solutions.

The best machines aren’t born from a single idea. They are the result of open dialogue, technical exchange, and mutual trust. That’s why every FAP project starts - and evolves - through continuous communication with our clients.

Our machines are built for foam extrusion, lamination, and custom converting applications, but their foundation is always the same: a collaborative process that aligns technology with our clients’ real needs.

That’s why collaboration is the natural evolution of our values - and the force that connects them all.

Our machinery is custom. So is the way we work.

From design to delivery, every department at FAP contributes in synergy. Technical, commercial, production, and service teams share the same vision and work together to achieve it.

We don’t just deliver equipment. We build partnerships.

Our most successful projects start with mutual understanding, grow through open feedback, and thrive on long-term collaboration. That’s how we go beyond meeting specifications - we exceed expectations.

When you choose FAP, you’re not just choosing a supplier. You’re choosing a technical partner who listens, supports, and co-creates with you.

Collaboration: The Sixth Pillar of FAP’s Identity

In previous months, we introduced four other core values of our daily approach:

Flexibility, our ability to adapt to the needs of each project and each client.

Listening, the attention we give to those who work with us and rely on us.

Integrity, the transparency and consistency that guide our words and actions.

Efficiency, Getting things done with clarity, speed, and purpose.

Reliability, How we build, how we respond, and how we follow through.

Looking for a partner who will understand your needs and turn your ideas into a high-performance solution?

Because when people work together, unique solutions - and lasting results - are born.

Why is it so important to choose the correct GMS dosing during the foaming/expansion process to produce high quality PE (polyethylene) or PP (polypropylene) foam material?

Simply because GMS, being an emulsifier and one of the most significant components, has a huge influence on many factors.

Let’s examine the following three main factors that help you to avoid the common mistakes:

During the foaming process, surface tension plays a crucial role. It refers to the physical effect that occurs when the blowing agent (such as butane, CO₂, or others) expands under heat inside the extruder. This phenomenon happens precisely when the blowing agent stops flowing and begins forming new foam cells at the point of critical expansion, stretching the walls of already existing cells.

The additive GMS (glycerol monostearate) helps reduce surface tension during this phase, facilitating smoother and more controlled cell formation. By lowering resistance on the cell walls, GMS improves the structural development of the foam, leading to more stable, uniform, and high-quality results.

Increasing the amount of GMS (glycerol monostearate) in the formulation can enhance the foam expansion process, but it also introduces several challenges. A high concentration of GMS tends to migrate from the lower layers of the foam to the upper layers, which creates a barrier to gas replacement with air. This results in:

On the other hand, an insufficient GMS concentration can lead to the premature release of gas before the foam has properly stabilized, often resulting in foam collapse during or after production.

This is why it is essential to control GMS dosing accurately through production testing and technical experience. Avoiding both excess and deficiency ensures optimal foam structure, stability, and future lamination performance.

Reduction of static charges on the surface of the foam during the production process - static charges accumulate on the surface of the foam as a result of friction - thus reducing the risk of fire

The lower the density of the foam (kg/m3) and the saturation/gassing of it, the more the GMS will influence these factors.

One of the most common challenges faced by foam manufacturers working with ultra-light, low-density foams is the issue of shrinkage or rapid post-extrusion expansion during the conditioning phase in storage. This often leads to the appearance of surface bubbles, cracks, or breaks that compromise foam quality.

While some producers experiment with additional additives labeled as "Anticolaps", these products typically act in the same way as GMS (glycerol monostearate), offering no added benefit when used together. Thus, their use is generally redundant.

The optimal GMS concentration depends on multiple production parameters, including:

Given these variables, accurate GMS dosing is essential for maintaining a stable foam structure and preventing post-production defects. A data-driven, experience-based approach to dosing ensures consistent quality and performance in PE and PP foam production.

Contact us today to improve your production quality and reduce waste.

You can’t fake reliability. It’s not about promises - it’s about showing up, doing the work, and doing it well, over and over again.

Reliability is a commitment we prove daily. It’s in every project delivered on time, every machine that runs for decades, and every time a client calls and knows we’ll pick up.

Trust is built over time, through consistency. We believe that being reliable means keeping our word when it’s easy - and especially when it’s not. That’s how long-term partnerships grow: with presence, responsibility, and results.

A machine isn’t reliable just because it works today. It’s reliable when it performs just as well after years of use. That’s why we test, refine, and stand behind everything we design.

Our clients know: if it’s built by FAP, it’s built to last.

Internally, we rely on each other. Every role matters, every handoff counts. We work in sync because we trust the people next to us. And that internal trust is what allows us to deliver externally - with confidence and continuity.

We bring this mindset into every relationship - with clients, suppliers, and colleagues. We aim for results, not just actions. Furthermore, we know that true efficiency is built on preparation, organization, and mutual respect. Because being efficient means being reliable.

In previous months, we introduced four other core values of our daily approach:

Flexibility, our ability to adapt to the needs of each project and each client.

Listening, the attention we give to those who work with us and rely on us.

Integrity, the transparency and consistency that guide our words and actions.

Efficiency. Getting things done with clarity, speed, and purpose.

Let's figure it out together.

But how far can we go without sacrificing product quality, mechanical strength, or dimensional stability?

But at the same time, how can we avoid ultimately getting an increase in technological defects associated with collapse, cell rupture, a decrease in the physical and mechanical properties of resistance to loads, etc. when reducing the density of physically polyethylene foam (EPE)? In addition, the question arises, what is the minimum density of the finished polyethylene foam product that we can obtain in the extrusion process so as not to have problems with quality later? Can we be sure that after a week of keeping the products in the warehouse we will not have to dispose of and granulate the entire batch or, even worse, pick up this defective batch of products from the customer's warehouse?

We often receive requests like:

"Can your extrusion line produce EPE foam with a density of 12 kg/m³ (0.75 lb/ft³) and still guarantee quality?"

"We bought a line recommended at a trade show, but we can’t achieve densities below 14 kg/m³ (0,87 lb/ft3). Can your engineers help us set it up properly?"

How to calculate the gas saturation coefficient of molten polymer and why it is impossible to cheat the laws of physics. Where is the limit of density reduction of physically foamed polyethylene and why most of the information on the market has nothing to do with REALITY.

Let us remind you that we are talking exclusively about foaming polyethylene, polypropylene or polystyrene by extrusion and the solubility of liquefied hydrocarbon gases in them under pressure.

Yes, of course, various tests were carried out, such as obtaining physically foamed ultra-low density polypropylene in the range of 10 kg/m3 (0,62 lb/ft3) by one of the largest manufacturers of foamed polyethylene in the world, but these tests did not find industrial application, since the process is simply impossible to control on an industrial scale.

It is no secret that the low density of physically foamed polyethylene is achieved by solubility in the melt of the largest amount of foaming agent, in our case, a gas such as Butane. The higher the viscosity of the gas and the greater its volume retained in the liquid state inside the extruder, the better the gas is dispersed into the melt and a smaller volume of it evaporates when the polymer exits the foam extrusion head (foam extrusion die).

During the extrusion of low-density polyethylene, the melt temperature in the extruder reaches 160-180 °C (320-356 °F) degrees and at this temperature it is necessary to maintain a minimum melt pressure (> 50 bar) so that butane has sufficient viscosity in the "borderline" state in order to mix with the polymer melt.

The technology of twin-screw extrusion with counter-rotation from FAP is capable of maintaining such a high melt pressure regardless of the pressure in the foam extruder head (foam extrusion die) and that is why this technology, unlike the most common single-screw extrusion on the market, is capable of producing both very thin foams with a thickness of 0.3-0.5 mm (1/64-1/50'') and foams with a thickness of 25-30 (1-1,2'') mm on the single line.

But even the counter-rotating twin-screw extrusion technology from FAP, which is the best technology for physically foamed polymers today, has a limit in the volume of gas dissolved in the polymer and, accordingly, the weight and density of the finished foam product.

Let’s break it down with an example:

Producing physically foamed polyethylene (EPE foam) with:

That is, if we take the volume of the polymer mass of 250 kg / hour in the extrusion process, we can dissolve in it only 10-11 kg of liquefied butane, taking into account the polymer processing temperature and the melt pressure both in the extruder and in the extrusion head. The rest of the introduced volume will evaporate during the foaming of the polymer with a sharp drop in pressure. Increasing the solubility of gas in the melt is complicated by the fact that it is necessary to both reduce the melt temperature to increase the viscosity of the gas and significantly increase the melt pressure.

But when the melt temperature is reduced to increase the viscosity of the gas, the viscosity of the polymer also increases, making it difficult to disperse the gas, and in the case of increasing the temperature to reduce the viscosity of the polymer melt, even with an increase in the melt pressure, we increase the time for the crystallization of the polymer after foaming and thus the foam loses more gas during evaporation, which leads to partial collapse.

The second limitation is that with such a low density of foam plastic, the walls and edges of the cells are very thin and, accordingly, the risk of shrinkage, collapse of the foam plastic, or rupture of the cells during gas expansion is very high and is almost 100%. Such a low density is not a problem for open-cell foam plastics such as polyurethane, since there is not such a high pressure difference in the cells as in closed-cell foams. If we consider foamed polyethylene with a density of 12 kg/m3 (0,75 lb/ft3) during production, we will see that the foaming coefficient is 77.08, and the volume of the polymer itself per 1 m3 of foam (finished product) will be only 1.297%. As you understand, these figures are on the verge of fantasy.

But how do we come across such light samples of physically closed-cell polyethylene foam at exhibitions? Today, more and more manufacturers declare such figures, misleading manufacturers. In fact, there is nothing unusual. As manufacturers, we measure the density during the production process, at the moment when the material is produced on the production extrusion line. But how does the density of foamed polyethylene change after the full degassing period, that is, when the butane inside each cell is replaced by air.

For visual calculations, let's take the same material of polyethylene foam with a thickness of 2 mm (1/12'') x a width of 2 m (6,6 ft) x a density of 15 kg / m3 (0,94 lb/ft3):

- The weight of one square meter of our material during the production process will be 31.8 grams,

- Based on the density of the dissolved gas and the warehouse temperature of + 15 °C degrees (59 °F), the weight of gas in 1 m2 (10,7 ft2) of material will be 4.05 grams,

- In the process of replacing gas with air for about 19-25 days, our 1 m2 (10,7 ft2) of foamed polyethylene will lose about 3.3 grams in weight, since the specific volume of air m3 / kg is 5.66 times higher than that of butane,

- As a result, after 19-25 days, 1 m2 (10,7 ft2) of our material will weigh approximately 28.5 grams, which is 10.4% lighter, and the density of this material will be 13.4 kg/m3 (0,8365 lb/ft3),

- And if we take the time for the gas to escape over 40-50 days, then the weight of our sample will change by as much as 14.5-16 % and, accordingly, the density will decrease and approach 12 kg/m3 (0,75 lb/ft3).

Thus, it is important to distinguish the time of measurements of the finished foam product and understand when these measurements were made.

✔ Counter-rotating twin-screw extruders

✔ Higher melt pressure and gas solubility

✔ Reliable low-density production

✔ Technical support and process optimization

✔ Full control over foam thickness and quality

Need to reduce your EPE production costs safely?

Talk to our team. We’ll help you reach the lowest density possible — without sacrificing performance or quality.

In the world of industrial machinery, where every second counts, we have learned that true efficiency is made of PREPARATION, RESPONSIBILITY, & ATTENTION TO DETAIL. It is about optimizing every stage of the process. And above all, it’s about respecting people’s time: our clients', our partners', and our team’s.

In FAP, efficiency is a way of working and a way of being. It means being present, responding quickly, and acting with clarity and purpose. In a competitive and fast-moving industrial world, we believe that availability and responsiveness make all the difference.

We offer effective solutions, and always give the smart answer at the right time. For us, efficiency is not just speed - it’s about DELIVERING VALUE.

Efficiency begins by being there when our clients and partners need us. From the first contact to after-sales support, we make sure that questions are answered promptly and that our team is easy to reach and ready to help.

We know that our clients’ time is precious. That’s why we act quickly - without ever compromising on quality.

Behind every solution we offer is a coordinated and well-structured team. We promote a culture of clarity and accountability, where each role is well-defined and priorities are shared. This allows us to optimize time and energy, internally and externally.

We work with clear goals and streamlined processes, so that every project progresses in an effective, timely, and accurate way.

We bring this mindset into every relationship - with clients, suppliers, and colleagues. We aim for results, not just actions. Furthermore, we know that true efficiency is built on preparation, organization, and mutual respect. Because being efficient means being reliable.

Fast, Clear, and Reliable Communication. We ensure every client receives rapid, accurate, and useful information. Questions are answered without delay, and solutions are proposed with clarity. Our partners can rely on us to move quickly and keep every interaction smooth and efficient.

Commitment to Timely Delivery. We plan carefully and execute precisely to meet agreed deadlines. From custom machinery to technical support.

Long-Term Collaboration Built on Responsiveness. Efficiency builds trust. Our clients know they can count on us not just for quick replies, but for consistent follow-through.

In previous months, we introduced three other core values of our daily approach:

• Flexibility, our ability to adapt to the needs of each project and each client.

• Listening, the attention we give to those who work with us and rely on us.

• Integrity, the transparency and consistency that guide our words and actions.

The industry leaders will reveal how FAP the latest CO2 foaming equipment, Borealis HMS PP Daploy™ 140HMS, and Royce Global functional additive masterbatches are transforming EPS foam production to improve both sustainability and efficiency. Through real-world case studies and expert insights, you’ll gain actionable strategies to enhance your performance, meet regulatory requirements, and reduce your environmental impact.

Meet the experts leading the change

Denisa George (Borealis) will explain how regulatory trends are pushing the shift toward eco-friendly foam solutions.

Francesco Poli (FAP) will introduce FAP’s groundbreaking CO2 foaming twin screw counter rotating extruders and its impact on efficiency and product consistency.

Sean Wilson (Global Royce) will reveal how functional additive masterbatches optimize production and enhance foam performance.

Antti Tynys (Borealis) will showcase the power of Polypropylene and its potential to revolutionize packaging, insulation, and other foam applications.

With the industry evolving fast, this webinar is your chance to stay ahead, gain insights from top industry leaders, and take part in the conversation that’s shaping the future of sustainable foaming.

Register Now!

It is no secret that each technology has its own advantages and disadvantages. When deciding to invest in the production of polyethylene (EPE), polypropylene (EPP) foam and polystyrene (EPS) it is important to understand:

What materials do you want to produce on foam extrusion line?

The "predictability" and stability of the production process plays a very important role. It must be assured that the quality parameters of the product (geometric dimensions, product density, cell structure, maturation process of the product in the warehouse) will be unchanged in every production batch produced. The foam production line should be automated to reduce the influence of the so-called "human" factor on the technological process of foaming, and to make the production process itself safe and highly efficient.

In this article we will give some examples of the competitive advantage of FAP foam extrusion lines with counter-rotating technology for the purpose of comparison with single-screw extrusion technology. We focus exclusively on polyethylene and polypropylene foaming processes by direct injection of pressurized gas into the polymer melt (physical foaming).

In contrast to single-screw extruder technology, twin-screw FAP extrusion technology ensures uniform melt and mechanical mixing of the polymer by grinding of material at the screw contact point, rather than by creating melt back pressure as is the case with single-screw extruder. This positively affects technological factors such as:

One of the main processes in the production of non-cross-linked physically foamed EPE, EPP, EPS is the mixing of the melt with gas. In the gas inlet area of the extruder, it is necessary to maintain the optimum pressure so that the gas is in the right state and has sufficient viscosity and density for dispersion and solubility in the molten polymer. But how does this affect the production process and the quality characteristics of the finished foam products?

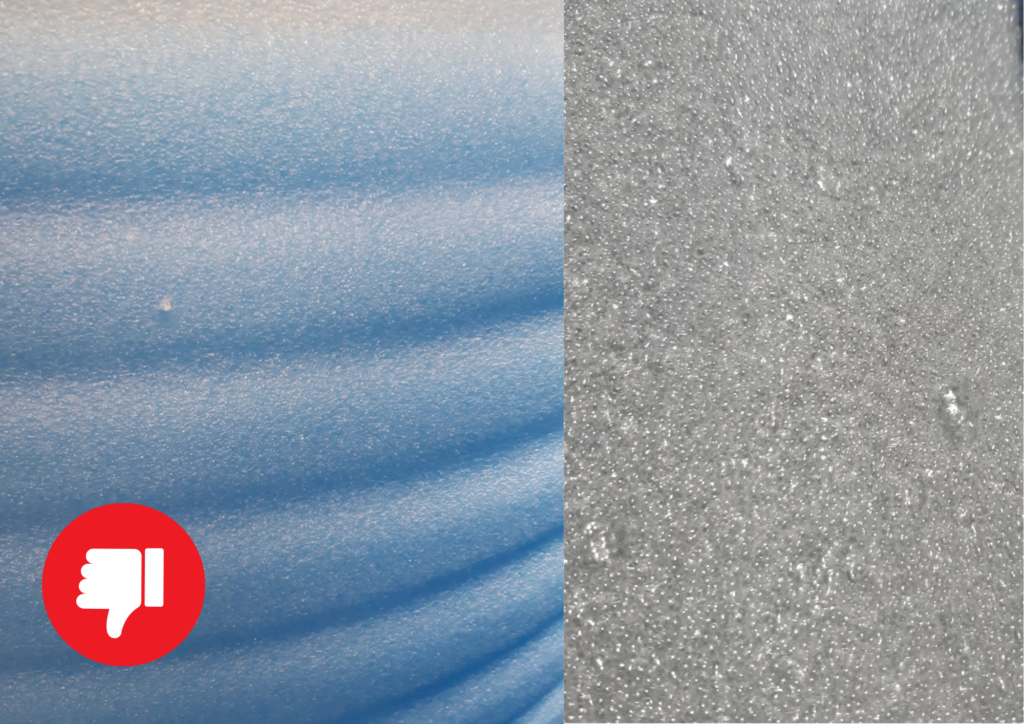

Photo 1. Production of 5 mm thick physically foamed polyethylene with high and frequent waves

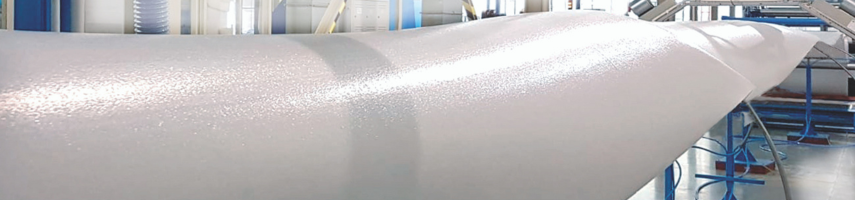

Photo 2. Production of physically foamed polyethylene with thickness of 20 mm with flat smooth surface

Photo 1 shows a 5 mm thick polyethylene foam product produced on a single-screw extrusion line. The material has a fairly frequent and high wave. This is because, in order to pressurize and maintain the required pressure in the gas injection zone of the single-screw extruder, it is not possible to use a sufficiently low pressure at the die outlet of extrusion head and an extrusion head is designed in such a way as to create back pressure in the extruder barrel in addition to the filter screen. This severely limits the production process and makes it practically impossible to produce polyethylene foams with high thicknesses (e.g. more than 12 mm).

3/4. Production of 5 mm thickness low density polypropylene foam with flat smooth surface on extrusion line FAP.

FAP foam extrusion lines (photo 2,3,4) equipped with two screws with counter-rotating movement that allow to create sufficient pressure in the gas inlet zone of the extruder even at extremely low pressure at the die outlet of the extrusion head. In addition, the unique design of the screws of the gas inlet zone allows changing the flow of the melt direction and to create a stronger mixing effect, which in turn allows dispersing the gas in the melt much better and finally to obtain foam with a more homogeneous fine cellular structure (Microcell Technology). All this allows the production of foamed polyethylene and polypropylene both at critically high pressure and at sufficiently low pressure, with a finished product thickness from 0.5 mm to 25 mm, with smooth surface of low-density foamed polyethylene and polypropylene without waves on the same extrusion line. This creates significant advantages in the formation of production costs of finished foam materials for our customers and makes the technology of FAP extrusion lines universal from many sides.

Due to the fact that FAP extrusion technology allows much better and faster cooling of the melt at start-up and adjustment of the extrusion line to the final product, faster and better mixing of colorants and additives due to mechanical contact and the unique screw design, it directly affects the cost of the finished product of polyethylene (EPE), polypropylene (EPP) foam and polystyrene (EPS). Stable production process, with controlled quality indicators, minimizes any risks of hidden defects of finished products, shrinkage of foam during degassing and violation of cell structure integrity, which generally affects production and cost of finished products.

Set-up time of FAP foam extrusion line from the moment of start-up to the first finished roll of EPE foam with thickness of 8-10 mm is on average not more than 65 minutes, which is about 15-20 minutes less than the time required for setting up EPE foam with the same thickness on a single-screw extruder with similar production capacity. This not only saves time and reduces the cost of power consumption, but also reduces the consumption of raw materials in the process of starting the line by 15-20%, affects the reduction of the minimum economically efficient production batch by 10-14%, as well as reducing the cost of placement and storage of products in the warehouse.