🚀 We are waiting for you at PLASTIMAGEN® MÉXICO 🤝

Come and visit Stand 1948 / 📅 07-10 November 2023

Our agent Francisco Güemes will be available to present you our cutting-edge technology for foam production, converting by FAP & VELA by FAP, will tell about 𝗮𝗱𝘃𝗮𝗻𝘁𝗮𝗴𝗲𝘀 𝗮𝗻𝗱 𝗴𝗿𝗲𝗮𝘁 𝗽𝗲𝗿𝗳𝗼𝗿𝗺𝗮𝗻𝗰𝗲 𝗼𝗳 𝗼𝘂𝗿 𝗹𝗶𝗻𝗲𝘀, 𝗲𝗾𝘂𝗶𝗽𝗺𝗲𝗻𝘁 𝗮𝗻𝗱 𝘂𝗻𝗶𝗾𝘂𝗲 𝘀𝗲𝗿𝘃𝗶𝗰𝗲𝘀 we offer, also show the markets for foam materials often that few know about.

FAP, Your Foam Extrusion Partner 🌎

FAP team wishes all participants fruitful and efficient work!

FAP, a personal approach with an international vocation, since 1987.

FAP is dedicated daily to the development of new solutions and innovative applications not yet present on the market, always trying to anticipate the needs of foam producers and the market. To meet the customers’ needs, and to ensure precise and complete answers, FAP has created an internal Italian Foam Centre to test granules and to produce special foam materials in little scale. During the last years numerous tests were carried out together with customers, producers of raw materials and research centers.

Thanks to the numerous requests in the recent months the samples of high-density polypropylene (PP) and polyethylene (PE) foam have been produced and tested, perfect for being thermoformed and laminated with the final use in various industrial sectors such as automotive, construction and food.

Furthermore, today the company is the protagonist of a courageous entrepreneurial choice. FAP invests over 5 million euros to build the site which provides the expansion of the new production area, that nowadays has become insufficient to manage the ever-increasing number of orders. Also, our Foam Centre will be expanded for research and development of expanded plastic materials in industrial scale, that has already solicited requests by companies all over the world including for example USA, Germany, Brazil, Chile, Saudi Arabia, France.

"We collaborate with companies that work, produce and study polymers: today companies have the opportunity to carry out tests in our Italian Foam Centre in little scale, but not to continue experimenting on industrial production machines”, Fabrizio Poli explains. “We build these machines and we want to share our rich experience creating a line specially dedicated for tests in industrial scale. Moreover, this center will be used by our company for the study of new materials and to improve processes in terms of energy efficiency", continues Poli, who has already established relations with the Polytechnic of Milan for the evaluation of an innovative material that FAP patented. "We are talking about a replacement of polystyrene material for the food sector with 100% recyclable foam produced using 100% natural gas CO2", Poli concludes.

Recyclable PP foam production with blowing agent 100% CO2

Today in our Italian Foam Centre thanks to internal foam extrusion line we are testing a 𝗻𝗲𝘄 𝗽𝗼𝗹𝘆𝗺𝗲𝗿 𝗺𝗼𝗱𝗶𝗳𝗶𝗲𝗿 for the project Foaming low-density polyethylene with 𝗰𝗮𝗿𝗯𝗼𝗻 𝗱𝗶𝗼𝘅𝗶𝗱𝗲 (CO2)🌍

P.S. The material is still very 🔥 as this video was made during the launch of the extrusion line.

Visit us at Plast Milano 2023

When: 5 - 8 September 2023, Milan, Italy

Where: Hall 15 B / Booth 145

See you soon! FAP team wishes all participants fruitful and efficient work!

FAP, a personal approach with an international vocation, since 1987.

We invite all our clients to contact us to get an entrance free ticket.

What are the most common technologies used in foam extruders for the production of non-cross linked physical expansion foam in polyethylene (or polypropylene)?

We can highlight 4 most famous technologies: Single Screw Foam Extruder, Tandem Foam Extruder, Twin Co-rotating Screws Foam Extruder & Twin Counter-rotating Screws Foam Extruder.

In the production process of expanded (foam) materials, factors of speed, pressure, temperature, cooling and mixing must be extremely precise in order to obtain perfect mixing combinations. Therefore, the equipment supplied with the foam machine and its crucial parts must be designed in order to have an extremely rapid and flexible response that allows instant optimization of what the foam production process requires.

And here are some of the reasons why FAP has chosen for over 35 years to design and construct 100% «Made in Italy» counter-rotating twin screw foam extruders. So we have decided to share with you and describe some of the great advantages of our foam extrusion lines.

- All components in granules are distributed at the entrance of the machine by the extremely precise gravimetric dosing station except the gas which is injected in the centre of the foam extruder machine.

- The foam machine never works "full mouth", the machine works in filling controlled by the flow rate of the dosing station and the speed of rotation of the screws. This process allows you to adjust the pressures of the mixture depending on the quantity and speed.

- The mixing is ensured by the mechanical work of the screw profiles which act by crushing the mixture at the point of contact of the screw profiles, and by reversing the mixture in the screw profiles, during the advancement of the mixing;

- The internal cooling is ensured by a circulation of water at controlled temperature, close to the screws and very reactive to the change of temperature setpoints!

All our machines are just like our children: as they "win" in competitions, we feel like proud parents, conscious of their prowess.

– FAP

| Thanks to the work of FAP team, we managed to achieve not only successful indicators in R&D field, to launch our new FAP VELA brand, but also to attract some new customers. After the vacation, we will be back full of energy and will continue to work this year even more successfully than ever before. Thanks to all our clients, partners and suppliers for the support and collaborations. For your requests: SA***@******LY.COM We will reply to all emails when we return. |

FAP does not only produce advanced equipment for foam, our team also loves getting immersed into the process of physical foaming of polyethylene and polypropylene.

We also share our experience with our clients and partners, trying to teach everything we know and study ourselves. Spending a huge number of hours in our laboratory, we study all the nuances to make the technological process of foaming as simple and safe as possible for you.

Today we will analyse two rather serious hidden technological errors in the production of polyethylene (PE) and polypropylene (PP) foam, which are not visible at first glance but can significantly affect the quality of products, the formation of defects and the efficiency of your production.

As for any kind of foamed polymers, physical foaming has its own nuances, and one of them is changes in the gas density in the polymer during and after foaming (expansion) due to its solubility.

Yes, after the production of the finished material, the expansion continues, since the gas is still hot and continues to expand. If this process is not properly controlled, it leads to many problems associated with the formation of cell wall destruction, the formation of bubbles on the material and, of course, the deterioration of its physical properties and its mechanical characteristics.

We know that many pipe insulation manufacturers have to face the problem of changing the internal diameter of the finished product due to wall expansion and subsequent deviation from the nomenclature requirements. Instead in the production of a packaging profile, the problem of excessive expansion can lead to a loss of profile geometry and, as a result, to the impossibility of using it due to poor fit. This will be a particularly big problem in the production of complex shaped profiles from physically foamed polyethylene, where it is necessary to achieve the most accurate geometric dimensions with minimal tolerances for deviations. The market is going in this direction very strongly and it would be very right strategy to compete in the field of complex figured profiles with the manufacturers of cross-linked foams XPE.

We faced a similar situation at one of client's factories, in the production of foamed pipe insulation, where during the degassing process the geometry changed either up or down, and the quality department often rejected entire batches of products. In this situation, the problem was solely in the wrong technological documentation, as well as in the methods of production and storage, since at another plant in the same region, operating on similar raw materials and identical equipment, such problems were reduced to almost zero.

What is the first reason of this main problem? The first and very serious error is that an improperly developed homogenization and melting process leads to excessive expansion of gas.

And this is a very big problem, especially in the production of foam insulation with complex shapes and tolerances or foam insulation, where a high modulus of elasticity is needed. We will not go into detail now on how this error affects the modulus of elasticity and sound insulation characteristics, if you need more information, you can contact to us.

The second reason follows from the first: overheating of the polymer mass and gas further increases the migration of GMS to the foam surface, creating an additional barrier to diffusion during the maturation of the foamed polymer.

This problem is 50% a consequence of the first technological error described above. The finished product (physically foamed polyethylene or polypropylene with gas like isobutane) requires a certain amount of time in the warehouse after manufacture before further use.

The degassing period depends on the thickness of the material, its density kg/m3, the number of meters in a roll, the temperature and humidity of the environment, the concentration and dosage of GMS, and the air exchange in the warehouse. The first and essential factor in the process of replacing gas with air is the migration of GMS to the surface of the foamed polymer.

This process occurs in any case, because GMS:

But with the wrong choice of GMS with a very low processing temperature and the wrong choice of melt and homogenization mode, you will greatly enhance this effect. This can be seen by the formation of a film or "crust" on the surface of the foam sometime after production, especially on foam with a small number of GSE (cells) per 1 cm2 and with large cells. This is due to the fact that, while migrating to the surface, GMS freezes, forming this same film and “crust” on the entire plane of the material, significantly complicating the degassing process.

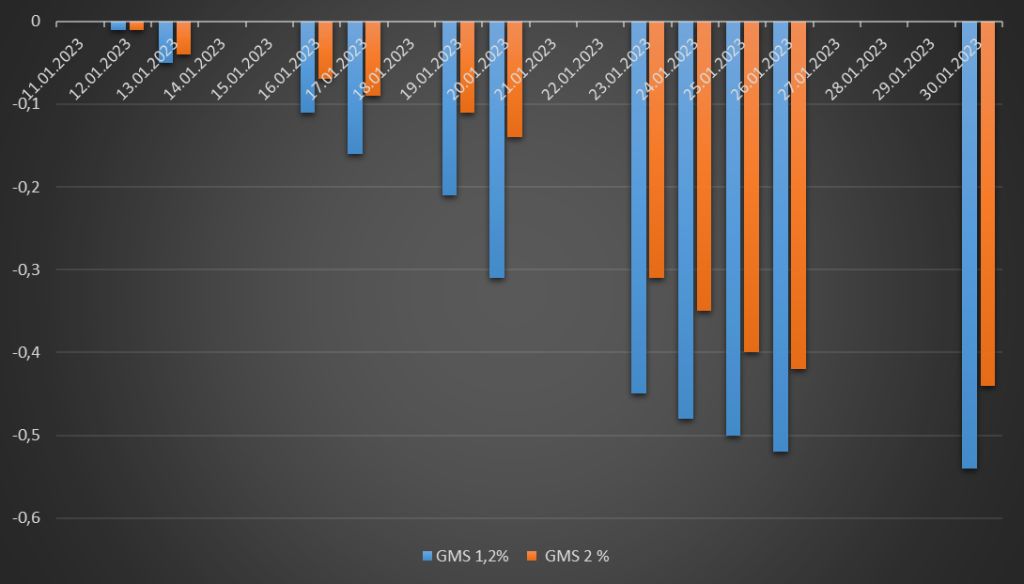

We did a small test to see how the emulsifier volume affects the degassing rate on polyethylene (PE) foam of 4 mm and 10 mm thickness with a density of 18-20 kg/m3, adding GMS at 2% and 1.2% of the total throughput. The results confirmed the fact that a decrease in the GMS concentration leads to a faster replacement of gas by air by 20.2% due to a decrease in its concentration on the foam surface.

Of course, reducing the dosage of GMS is not the best way to shorten and normalize the terms of gas exchange and reduce the pressure inside the cell, we only focus your attention on the correct choice of GMS, its concentration, formulation and processing temperature in the process of foaming in order to prevent excessive migration of GMS to the surface of the foam and excessive pressure of the expanding gas in the cell of the foamed polymer.

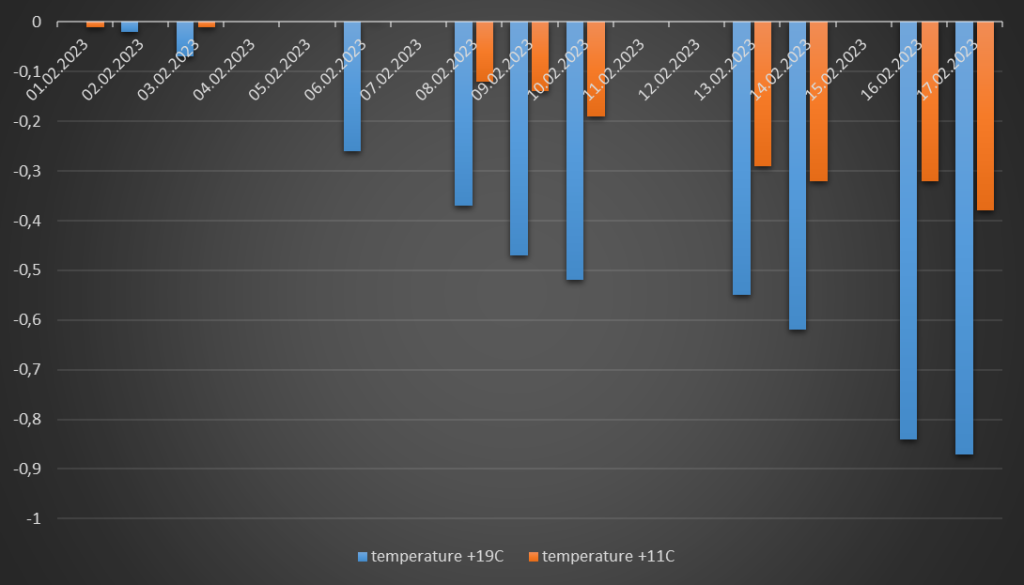

In addition, the storage conditions of polyethylene (PE) and polypropylene (PP) foam can also adversely affect the degassing period. Our tests on various materials with a thickness of 2 mm, 3 mm, 5 mm and 10 mm with a density of 18-20 kg / m3 show that the optimal temperature regime for storing foam finished materials of polyethylene and polypropylene is from 18 to 23 °C at a humidity of 30-40%.

For example, the degassing period (replacement of gas with air) of material in the form of rolls at a storage temperature of +10.3°C and a humidity of 38% is on average of 41.7% slower than the rate of degassing of a similar material during storage at +18.6°C and 30% of humidity.

Thus, an excess of residual gas significantly affects the further process of lamination of polyethylene and polypropylene foam with each other.

The fact is that when the foamed polymer is heated and melted with an air blade and a hot roll, the gas leaves the cells and expands sharply between the layers during lamination, preventing high-quality adhesion. Moreover, delamination may not be immediately noticeable, but occurs after a few hours as the gas expands and pressure is created between the layers.

Birth of new FAP VELA brand: resumption of designing and machine construction with full technical service for Vela’s customers.

FAP has always been inspired by the versatile solutions of the Spanish company Vela which represents the surname of its founder and inventor. Due to this fact the new FAP VELA brand was born: the union of their passions for high-performance and intuitive solutions and international experience. This fusion will allow to approach the market with the extension of the new range of solutions, which are extremely versatile machines for the packaging sector:

| Cutting machines for the production of sheets in bubble film and foam sheets from rolls. The versatility allows it to perform a wide, processing different sizes materials. No damage of the material. | Welding machines for the automatic production of different size of bags in bubble film and foam. It features a stacking system that does not damage the material. | Folders the preparation of rolls, transform a plain material into two half-tubes with mechanism of folding: high quality and a large batch production of bags. |

FAP presents the new FlexCut16 cutting machine

FlexCut16 is SHEET CUTTER MACHINE - A HIGHLY VERSATILE & FUNCTIONAL SOLUTION FOR THE PRODUCTION OF SHEETS / FORMATS from bubble wrap and foam.

Its versatility allows to perform a wide variety of functions, processing different sizes, thicknesses and materials. The machine produces a regular cut with great precision in the size of the format. It features a stacking system that does not damage the material.

✔ Fully automatic

✔ High production capacity

✔ High quality of the finished product

✔ User-friendly operation

Beneficiary: FAP SRL

Project management by: Politecnico di Milano

Finally FAP's long and rich international experience is at the complete disposal of the entire FOAM WORLD.

Thanks to foam extruder in our internal laboratory together with our customers, raw material producers and research centers, we create, test, approve new solutions capable of anticipating the ever-changing foam market demand or even changing the competitive scenario.

We dedicate ourselves daily to the development of innovative technologies and to the study of new fields of application of polyethylene (PE) and polypropylene (PP) foam (expanded films).

Laboratory foam extruder is a perfect copy of FAP extruders of industrial scale with “direct gazing” technology and high performance characteristics. The foam extrusion line has nr.3 (three) extrusion dies (heads): round, flat, tube/pipe.

Researchers, producers of raw materials, producers of foam materials and start-up businesses are welcome to discover the benefits of FAP technology: