For FAP, sustainability means doing our work well, every day, through the technical and organizational choices that we have learned to make increasingly smarter over time.

In practice, this translates into:

• optimizing energy consumption on our lines and machinery;

• extending the lifecycle of production plants, as FAP machines continue to operate at full capacity even after 20–30 years - with electrical components being the only part that may require a complete revision;

• designing tailor-made solutions, avoiding any form of overproduction or unnecessary modules;

• supporting customers with preventive maintenance to reduce waste, consumption, and emergencies;

• continuously testing recycled materials and blowing agents with lower environmental impact and higher safety levels;

• collaborating with reliable suppliers to consistently improve our technological offering;

• structuring our internal processes to optimize workflow, materials, labor, and logistics - ensuring continuity and long-term quality.

Our commitment is not limited to a single year: it is a continuous journey.

We have carried out tests with high-percentage recycled and innovative materials, including CO₂ expansion; performed audits on customers’ lines to identify inefficiencies; invested in internal training; and made targeted purchases that improve the way we design and build our machines.

These are concrete actions - often quiet or taken for granted - that, over time, create a clear direction: giving value to the future through technical choices that improve the present.

Because there is no Listening, Integrity, Efficiency, Innovation, Experience…

without an idea of future worth protecting.

And this future is something we want to build together with you.

Throughout the year, we have explored our values one by one - the principles that guide how we design, build, and collaborate: from the way we listen to customers, to the integrity behind every decision, to the efficiency, innovation, and experience we bring into each project.

To those who chose us, who engaged with us, who challenged us.

Each project developed together has helped us grow and do our work better.

May 2026 bring new ideas, new energy, and new opportunities -

with the same trust and collaboration that have accompanied our journey so far.

With warm regards,

The FAP Team

Investing in a foam extrusion line is a strategic decision for manufacturers of expanded polyethylene (EPE), expanded polypropylene (EPP), or expanded polystyrene (EPS). A properly engineered line ensures consistent quality, reduced energy consumption, and an efficient and stable production process. A choice based solely on price, however, can generate instability, high scrap rates, and long-term operating costs.

This article outlines the essential criteria for evaluating an investment focused on quality, energy efficiency, and long-term sustainability.

Many companies approach the purchase of a foam extrusion line with a specific machine already in mind. However, technical analysis often reveals that real production needs require different throughput levels, more advanced automation, or simpler and more efficient configurations.

For this reason, the first step is to clearly define the expected outcome. Only then is it possible to identify a coherent solution that avoids oversizing, prevents long-term limitations, and supports sustainable growth.

Every producer has unique requirements: materials, factory layout, production volumes, thicknesses, densities, and final applications. Customization is therefore essential.

Designing a tailored extrusion line means defining every element — from screw and die design to gas injection, automation, and downstream integration — according to the real needs of the process, ensuring higher quality, better energy performance, and greater production stability.

To select the correct extrusion line, it is essential to know:

Only after this analysis is it possible to compare technologies and configurations.

The chosen technology determines process stability, production flexibility, foam quality, and the overall energy efficiency of the line.

Suitable for standard products, less flexible for thin gauges or low densities.

A tandem configuration uses two extruders in series: the first for melting and mixing, the second for cooling the melt. It is a reliable but less flexible technology, suitable for established foam production. It requires more space, precise balancing between the two extruders, and more intensive maintenance due to the dual structure.

Counter-rotating twin-screw technology delivers superior melt homogenization thanks to its high mixing capability and controlled compression along the screw profile. This enables precise and uniform gas distribution - essential for regular cell structure, stable density, and smooth surfaces even at reduced thicknesses.

The process is extremely stable, with minimal variation from shift to shift, and supports advanced materials such as EPP foam, PE/PP blends, and higher-performance technical foams.

Greater mixing efficiency inherently reduces scrap and process deviations, improving energy consumption per kg produced and making twin-screw technology a sustainable, high-quality choice for long-term performance.

Foam quality is determined primarily inside the extruder. An advanced line must ensure homogeneous melt, regular cells, stable density, smooth surfaces, accurate thermal control, and repeatable performance.

These results depend on: optimized screw and die (head) designs, thermal profiles monitored by multiple sensors in critical zones, continuous pressure monitoring, precise gas injection and distribution, and effective primary cooling within the extruder.

When these parameters are well controlled, the process remains stable without the need for external compensation systems.

After the extruder, cooling and winding determine the dimensional stability and surface quality of the foam sheet. A modern line must include: uniform cooling, suitable calibrators, guiding and stabilization systems, and effective post-expansion control during winding.

A truly modern system offers advanced automation, save-and-repeat recipes, intuitive interfaces, integration with downstream equipment, easy maintenance and recipe changeover, and high safety standards.

A simple and well-controlled operation increases production continuity and reduces scrap.

Sustainability is measured every day in production. It is essential to consider: specific energy consumption, thermal efficiency of the system, process stability, required maintenance, and component lifespan.

An efficient line consumes less, generates less waste, and reduces overall operating costs.

Choosing a foam extrusion line means investing in a technology that must guarantee continuity, flexibility, efficiency, and quality for many years. An evaluation based on objectives, technology, and technical vision reduces consumption, minimizes waste, and increases competitiveness.

It is an investment that combines performance, environmental responsibility, and long-term development.

The journey does not end with the installation of the foam extrusion line. Competent technical support, spare parts availability, training, and ongoing updates are essential to maintain high performance over time.

A long-term partnership helps tackle new applications, improve formulations, and adapt production to market evolution.

In foam extrusion, technology is essential — but it is never the only answer.

Behind every line there is a project, behind every project there is a goal, and behind every goal there is a company that wants to grow.

It is in this space - between what you want to achieve today and what you can build tomorrow - that the value of a true partnership is created.

Working with FAP means facing production challenges together, transforming uncertainties into clear decisions, and evolving the line in step with your market. It is not only about mastering extrusion, but about listening, adapting, and guiding the process: a shared path where the machine becomes a tool, and the relationship the lever that maximizes its performance.

If you want to explore a different way of designing the future of your production - more confident, more solid, more results-oriented - we are ready to walk by your side.

Because machines produce foam, but partnerships build success.

We’d like to extend a warm welcome to all the new subscribers after visiting us at K2025. It was a true pleasure to meet so many people who shared their stories, challenges, and projects with us - moments of real dialogue that remind us why we love what we do.

At FAP, every new connection starts with a conversation, and every conversation begins with one essential value: Transparency.

Transparency is a daily choice that shapes how we work and how we relate to people. It’s the foundation of trust - the invisible link that makes every partnership stronger. When communication is open and sincere, when questions are answered clearly and expectations are aligned, collaboration stops being a transaction and becomes a shared journey.

In our relationship with customers and partners, transparency means being clear from the very beginning: about what’s possible, what’s not, and what we’re still exploring together. We talk about deadlines, limits, opportunities, and solutions with the same honesty we expect in return. Because we believe that good technology starts with good communication - and that progress can only happen when both sides see the full picture.

Within our team, transparency is what connects ideas, people, and responsibilities. We keep each other informed, involved, and aware of the bigger vision. We share feedback, successes, and difficulties, because that’s how we learn and grow.

At FAP, we see transparency as a form of respect. It means telling things as they are, not as they sound better. It means keeping our promises, but also admitting when we need time to rethink or improve. And it means showing, with clarity and sincerity, how much we care about the people who choose to work with us.

In previous months, we introduced the following:

Warm regards, the FAP team

This year’s exhibition was not only a meeting point for those who already had clear ideas and ongoing projects, but also a place of new encounters, where meaningful collaborations started to take shape.

Many of these are already turning into synergies between companies and partners, proving that innovation today is possible only when expertise and technology meet across multiple fronts.

At FAP, we design and build foam extrusion lines, lamination, winding, and cutting machines that adapt to different materials and applications.

During the K2025, we had the chance to discuss our most advanced twin-screw counter-rotating extrusion technology, developed to process both virgin and recycled raw materials, enabling the production of high-performance and sustainable foams such as polypropylene foam or polyethyene foam with high PCR content.

That’s why we’re proud to collaborate with leading material producers such as Borealis, Ravago, Sabic, and others – companies that share our belief that progress is built through partnership.

Because when you combine technological know-how, material innovation, and genuine collaboration, you gain a real competitive advantage.

While we welcomed our partners and new contacts at K2025, it’s useful to take a step back and look at the broader industry in which we all operate - to understand how our reality fits, and what the outlook is for everyone.

Focus on tailor-made, flexible solutions

Instead of “one-size-fits-all,” we project machines that are configurable and adaptable to many materials (virgin, recycled, light-weight,etc), multiple formats (large or custom widths), and various end-uses (packaging, technical films, converting).

Collaboration as a competitive edge

Through our partnerships and by working directly with customers in co-design mode, we integrate material and machine technology in one motion. This gives our clients a head start and provides us with a distinctive edge in innovation.

Technology-led but value-driven

Our twin-screw extrusion lines, custom lamination, and large-format winding and cutting machines are advanced solutions - but the story isn’t just about the machines themselves. It’s about what our customers achieve with them: stable ana sustainable production, reduced cost per kilogram, lower waste, and access to new markets.

Sustainability and circularity built in

As the market demands more recycled content, eco-friendly foams, and energy-efficient machinery, we ensure our lines support PCR materials, reduce energy consumption, and allow flexible widths and converting formats that optimise yield and minimise scrap.

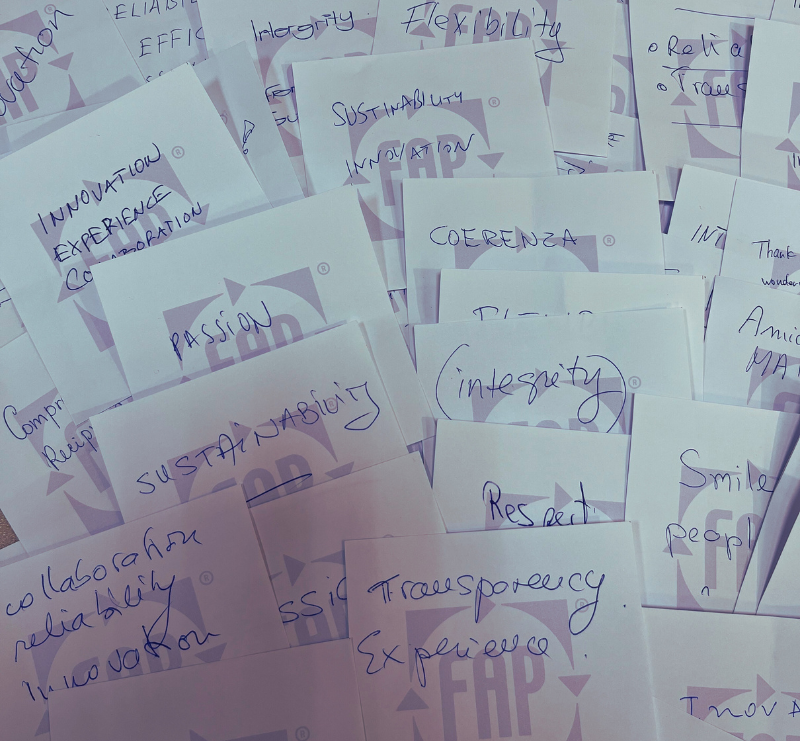

And since many of you took part in our Values Corner, we’re happy to reveal the most voted values that guided our community this year:

Innovation – the engine of change

Collaboration, Reliability, Passion – because nothing meaningful is built alone

Experience, Integrity, Sustainability – because true values grow over time

Each note you left in our box was more than a word – it was a piece of who you are.

Together, they painted a clear picture: behind every technology, there are people who believe in something bigger.

We still have two more values to share in November and December, but one thing is already certain:

Real innovation starts when values meet.

We are proud to announce our collaboration with Ravago on the development of Foamed RAVAPURA® LDPE, a breakthrough material containing over 70% certified post-consumer recycled (PCR) content.

The trials were carried out on FAP’s twin-screw counter-rotating foam extrusion line, installed at our Italian Foam Centre - where new materials and processes come to life before reaching industrial scale.

By combining Ravago’s expertise in recycled raw materials with FAP’s advanced foam extrusion technology, this joint project proves that sustainability and performance can go hand in hand.

The result: a lightweight, stable, and eco-efficient LDPE foam with reduced environmental impact and excellent mechanical properties.

At FAP, we believe in collaboration as a catalyst for innovation - turning ideas into tangible results for a more sustainable industry.

This October we chose to talk about Passion - and the timing couldn’t be better. In a few days we’ll be at K2025 in Düsseldorf, Hall 16 Booth D68, the most important exhibition for the plastics and machinery industry. And the fact that the tenth value we are sharing in our journey is Passion, right in the month of the fair, is no coincidence.

In 2025, FAP chose to tell its story through a symbolic and visual journey: the 12 values of our Manifesto, the heartbeat of who we are. Each month we highlight one value, represented by an original illustration in true FAP style - technical yet imaginative, and uniquely ours. October is Passion, and it will also take shape inside our stand at K2025, designed not only to present tecnical solutions in Extrusion, Winding, Laminating, Cutting and Welding, but to reflect our way of being: an invitation to dialogue, to discover new perspectives and to build new opportunities.

Why passion? Because without it, technology alone is not enough.

Passion is what makes us dedicate time and energy to every detail of a project. It’s what pushes us to run one more test, to explore a new material, to design a solution that didn’t exist before. It’s what keeps us focused not only on machines, but on the people who will use them - operators, engineers, entrepreneurs - each with their own challenges and expectations.

It means:

At Hall 16 Booth D68, our booth will reflect not just our technical expertise, but the passion that inspires it. Because what makes each solution unique is not only the technology, but the people who stand behind it.

In previous months, we introduced other core values of our daily approach:

Flexibility, Our ability to adapt to the needs of each project and each client.

Listening, The attention we give to those who work with us and rely on us.

Integrity, The transparency and consistency that guide our words and actions.

Efficiency, Getting things done with clarity, speed, and purpose.

Reliability, How we build, how we respond, and how we follow through.

Collaboration, We believe in co-creating value.

Innovation, Only has value when it generates Real Impact.

Growth begins by looking inward.

Experience is the compass that guides us when the road isn’t mapped.

Discover Our Tailor-Made Technologies for Your ProductionFrom October 8 to 15, we’ll be in Düsseldorf at K2025, the world’s leading plastics and rubber trade fair.

You’ll find us at Hall 16 / Booth 16D68 – and we’d love to meet you.

Industry is evolving, markets are moving fast, and challenges are becoming increasingly complex. In this context, a "one-size-fits-all" technology is no longer sufficient. At FAP, we always start with one thing: the customer's project.

For over 38 years, we have been designing and building tailor-made machines for the extrusion, winding, lamination, cutting, welding and other converting solutions. Now led by the second generation, FAP continues a journey started in 1987, establishing itself as a reliable partner for both Italian and international customers. From large industrial groups to specialized manufacturers, our clients share one common need: they are not just looking for a machine. They are looking for a solution - and for someone who truly listens.

At FAP, solutions start from a real need - or rather, from a challenge. In recent years, over 70% of our projects have been completely customized. Customers come to us with unique requests, unconventional materials, and often out-of-standard production goals. Whether it’s a twin-screw extruder for foam materials, a lamination line for a patented thermoplastic material, a high-precision cutter for different plastic flexible materials, or a winder designed for high-density or ultra-light rolls, each machine is developed as part of a true collaboration.

One of the biggest issues in the market today is the lack of flexibility. Many manufacturers only offer what is already in their catalogue. Customization is often limited and expensive. FAP chooses a different path. We walk alongside the customer from day one. Together, we define the problem, explore options, and co-design the solution. This shared approach leads to smarter decisions and machines that not only tackle challenges but open new business opportunities. Our team of mechanical, electrical and software engineers work with great attention to every detail to ensure that the final machine truly reflects the customer’s production and business goals. This is what makes every FAP machine unique.

• A complete extrusion line with a double winding unit, developed together with the customer to produce ultra-thin expanded polypropylene with CO₂, combining energy efficiency with extreme film control precision.

• A lamination line designed to bond high-density thermoplastic material with nonwoven fabric, for a highly technical application in the construction sector.

• A tailor-made cutting machine "not available on the market," capable of precise work on barrier film and other flexible films, where the client needed a completely out-of-standard solution.

"What started as an ambitious idea has become a fully customized lamination line – the very first for our start-up. Together with FAP, we reworked the project multiple times, refining every detail until we reached the right solution. The result? A brand-new production process, built from scratch. What we appreciated most was their ability to stay by our side at every step, combining flexibility with true technical know-how."

The FAP offering includes versatile and modular solutions for:

• Extrusion lines for foam film, tubes and profiles, with counter-rotating twin-screw technology for materials like EPE, EPP, EPS, combined with polyolefins such as LDPE + MLLDPE, PP + TPE, PS + HIPS, PP + EVA. One extruder, infinite product diversification possibilities.

• High-efficiency extrusion heads, designed for the production of physically expanded closed-cell polymer foams. They provide consistent structure, excellent cell uniformity and superior quality. Compatibility with gases such as Isobutane, n-Butane, Propane/Butane and CO₂ allows for more efficient, sustainable, and economical production.

• Automatic and semi-automatic winders, designed for ultra-low-density or high densities foams, and bubble films, with various levels of automation.

• Lamination lines, now more in demand than ever, suitable for a variety of sectors for the production of barrier films, multilayer foam materials and special applications. Dedicated for lamination of foam, EVA, bubble film with materials such as HDPE, LDPE, metallized films, paper + HDPE, aluminium + LDPE, metallized lavsan, waterproof polymeric films, nonwoven fabric and others.

• Cutting machines for different flexible plastic materials and thicknesses.

• Bag-making machines for foam and bubble film, flexible, high-productivity and built to last.

Behind every technology there are people, visions and shared choices. Our approach to innovation comes from this awareness: working together, in open dialogue with those who share the same goals. We shared this story during the international webinar "Advancing Foam Sustainability", organized with Borealis, one of the world’s leading suppliers of sustainable polyolefin solutions. On that occasion, we showcased how our latest CO₂ foam technology, combined with HMS PP Daploy™ from Borealis and Royce Global functional additives, is revolutionizing foam production, improving both sustainability and industrial efficiency.

A few months later, we were invited to the Borealis Innovation Headquarters in Linz for two days of technical exchange and co-design. It was a concrete opportunity to further develop counter-rotating twin-screw extruders, a technology that FAP continues to evolve in close synergy with its customers, to meet increasingly complex production challenges. These technical networking moments are more than just visibility opportunities: they are real growth milestones for us, where knowledge is exchanged, ideas are challenged and solutions take shape from different perspectives - but united by one goal: building the future of industry.

New European rules are reshaping the packaging industry: by 2030, all packaging must be recyclable, contain post-consumer recycled (PCR) material, and move towards reuse and refill. For producers, this is not just compliance – it’s a transformation.

So we recently joined forces with Ravago, Sabic and Borealis to test PCR LDPE granules on a small-scale FAP twin-screw foam extruder, exploring formulations with high recycled content. The results? High quality foam, reliable performance, even at low densities. For us, these trials are not only a way to support our customers, but also a message to all foam packaging producers: by staying closely connected with raw material suppliers, we make our technology available to process even the most demanding new materials shaped by environmental requirements. Because anticipating change together is the best way to turn compliance into competitiveness.

But this year, there’s more than just technical solutions.

Inside our booth, we’re creating something unexpected and emotional.

It’s not about automation or technical features. It’s about what makes us human.

At FAP, we believe that our values are the real roots of everything we do. Each month of this year, we highlight one core value - Listening, Integrity, Efficiency, Innovation - and show how it drives our daily work, from engineering to after-sales service.

At K2025, we’ll celebrate these principles with a dedicated Values Corner – a space to pause, reflect, and reconnect with what matters most.

Because in today’s world, where automation, high-speed production, and streamlined processes dominate, we need to remember what keeps companies and people grounded.

Like the roots of a tree, values are invisible but essential: they support growth, give direction, and connect us to something meaningful - even as everything around us accelerates.

With more than 3,000 exhibitors at K2025, it’s easy to get lost in the noise of machines and innovation.

That’s why we invite you to slow down and meet us.

Not just to explore high-performance foam extrusion technology for example, but to have a real, valuable conversation.

Let’s talk about your production challenges, your goals, and how we can support you create your next big success - with technology that fits your process, and a team that’s here for you.

Because your project deserves more than a standard solution.

It deserves our expertise - and our attention.

📍 We’re already scheduling meetings for K2025.

If you’d like to reserve a time slot, get in touch with us.

We’ll be there.

Will you?

It’s not a title. Not a number of years. It’s what you do when things get complicated.

At FAP, when we talk about experience, we don’t just mean our history - we mean everything we’ve learned by facing new challenges every day.

Experience is when you truly listen to a customer and understand what they need, even if they’re struggling to explain it.

It’s when, faced with a problem, you don’t stop - you change perspective. And you find a way forward.

We’ve designed and built hundreds and hundreds of machines. But what really matters isn’t the number - it’s the details.

Every customer has taught us something. Every project has made us better. Every mistake has made us stronger.

You won’t find that kind of knowledge in a manual.

It lives in the hands that weld, in the eyes that review a drawing, in the voice that advises a customer like a colleague.

It’s what makes our work faster, more effective - and more human.

We can’t foresee everything. But we can face anything.

Our approach is simple: understand, analyze, solve.

We do it alongside our clients, in open dialogue.

And we do it internally, supporting one another, sharing knowledge, and offering our experience to those who have less.

Because for us, experience also means generosity - the ability to pass on what you’ve learned.

Every FAP machine is different, because every need is different.

And often, behind a request, there’s something the customer can’t quite express: a new production need, a non-standard material, a space or time constraint.

Not as a ready-made solution, but as a way of adapting.

Of creating something that works - really works.

Of turning a problem into an opportunity.

In previous months, we introduced other core values of our daily approach:

Flexibility, Our ability to adapt to the needs of each project and each client.

Listening, The attention we give to those who work with us and rely on us.

Integrity, The transparency and consistency that guide our words and actions.

Efficiency, Getting things done with clarity, speed, and purpose.

Reliability, How we build, how we respond, and how we follow through.

Collaboration, We believe in co-creating value.

Innovation, Only has value when it generates Real Impact.

Growth begins by looking inward.

If you’re looking for a partner who doesn’t just give you an answer - but the answer that works - we’re here.

With experience you can see, feel, and rely on.

The technical guide that explains how foam quality is really created – and why not all twin-screw systems are the same.

In physical-expansion foam extrusion, mixing is the most decisive variable in the entire process. It is not a detail: it is the point where final foam material quality, process stability and the overall sustainability of production are defined.

Foam quality is not created at the die.

It is created in the melt.

During the production of EPE, EPP, EPS and technical blends, the melt must meet extremely precise conditions:

If any element deviates – even slightly – defects appear immediately:

This is why truly advanced foam extrusion lines – such as those engineered by FAP – are designed around one central engineering principle:

The melt must be governed.

A high-quality melt in physical foam extrusion with direct gas injection shows:

When these conditions are met, results are immediate:

This is what separates a stable extrusion line from a line that works “only in ideal conditions”.

Suitable for standard products.

Limited when looking for special productions, variable thicknesses, or high-quality surfaces.

Mixing in the first extruder, cooling in the second.

Stable but requires fine balance between the two machines and offers a narrower processing window.

The FAP counter-rotating twin-screw configuration represents the most advanced solution for stable melt processing in foam extrusion thanks to:

• Controlled, uniform mechanical action

Avoids peaks that degrade the polymer or alter gas solubility.

• Progressive, consistent compression

Stabilises pressure and viscosity – essential for proper cell structure.

• Homogeneous gas distribution across the entire melt volume

Not just mixing: true gas solubilisation.

• Superior heat exchange

FAP geometry enables precise thermal control, avoiding hot and cold spots.

• Intrinsic melt stability and repeatability

The hallmark of FAP technology:

the ability to deliver the same quality, every shift, on every recipe.

And here lies the key message:

Not all twin-screws are the same.

The difference is not in the mechanics: it’s in the control.

In physical expansion, melt and gas must form a stable system.

If mixing is not perfect:

But when melt and gas are governed:

Most importantly:

A governed line is a more sustainable line.

Superior mixing delivers immediate environmental benefits:

In foam production, sustainability is in the process.

An extrusion line with stable mixing – like FAP lines – shows:

The question is not “Which screw do you use?”

The real question is:

“Can the foam extruder produce the same foam every day, without variations?”

If the answer is yes, then the technology is truly advanced.

For markets requiring:

Mixing is not a function:

it is a production strategy.

And when it is integrated correctly:

The counter-rotating twin-screw is only the starting point.

The real value comes from how FAP designs, governs and integrates the melt+gas process.

If you want to improve stability, surface quality, density control and sustainability in your foam production, we are ready to explore the most suitable solution for your goals.

Because:

Machines produce the foam.

Partnerships build success.

In a world that changes every day, staying still is not an option.

That’s why at FAP, we’ve chosen to grow – together.

Growth, for us, is not a destination. It’s a daily choice.

It’s what pushes us to ask better questions, embrace new challenges, and become better - as people, as professionals, and as a team.

At FAP, we believe that real growth happens when learning becomes part of your culture. That’s why we invest in training: from technical updates to language support, from safety to commercial skills.

Every course is a tool - not only to perform better, but to think differently.

And when our team evolves, the value we deliver to our clients evolves too.

But growth isn’t just about acquiring knowledge. Sometimes it means stopping to look inward.

We’ve taken the time to question our processes, improve our workflow, and face inefficiencies head-on.

This requires courage and collaboration. And it’s through these internal reflections that we’ve built a stronger, more agile organization - one that works with clarity, shared vision, and trust.

There’s also a more subtle kind of growth. The kind that doesn’t show up on spreadsheets but is felt in the everyday atmosphere.

At FAP, we take care of our environment - not only the physical one, but the emotional one too.

Respect, listening, space for ideas: these are the conditions where people can truly thrive.

Because no machine can do what people do when they feel valued and heard.

And then there’s the growth that challenges us. The unexpected project. The client request that seems impossible. The moment when time is short, specs are unclear, and the pressure is high.

We’ve learned to welcome those moments.

They’re the ones that push us to stretch, to create, and to build something that didn’t exist before.

Still, we never want to grow for the sake of it. Growth without meaning is just movement.

What we want is growth with purpose – rooted in our values, aligned with who we are.

We want to grow in competence, but also in relationships.

To grow in results, but never lose our human side.

To grow without losing the essence that has always made FAP… FAP.

In previous months, we introduced other core values of our daily approach:

Flexibility, Our ability to adapt to the needs of each project and each client.

Listening, The attention we give to those who work with us and rely on us.

Integrity, The transparency and consistency that guide our words and actions.

Efficiency, Getting things done with clarity, speed, and purpose.

Reliability, How we build, how we respond, and how we follow through.

Collaboration, We believe in co-creating value.

Innovation, Only has value when it generates Real Impact.

We don’t have all the answers. But we’re not afraid to learn.

If you’re looking for a partner who sees every project as a chance to evolve -

we’re ready.