After a year of informal activities setting the groundwork, WIP-IT is now formally constituted, complete with its own Statute, Manifesto, Code of Conduct, and Regulations. This new structure brings together entrepreneurs, employees, managers, and freelancers, all dedicated to fostering positive change in an industry traditionally dominated by male presence.

Association Goals

WIP-IT’s mission focuses on promoting inclusivity and social and environmental sustainability within the industry. The association aims to enhance the image of plastic materials through their sustainable uses and to develop a strong network of support and collaboration among female professionals. WIP-IT's values and principles are designed to have a significant impact on the cultural, social, and environmental framework of the plastics sector.

First Assembly: Participation, Elections, and Future Goals

The first assembly was held in Cremona on October 29, 2024, with over 50 new members joining the event, eager to share the association’s vision. During the assembly, the new positions were elected for the next term (until 2028):

The assembly also presented an overview of the projects completed over the past year and laid out plans for the future. The focus will be on education and training initiatives through events and courses, aimed at building skills and awareness among members. Key topics will include sustainable innovation in plastic materials and best practices for use and recycling.

Commitment to Inclusivity and Social Impact

Membership is open to individuals, as well as companies and organizations, who can participate as supporting or affiliated members. Member companies commit to fostering an inclusive work environment, ensuring equal opportunities, and supporting work-life balance for their employees.

The next Women in Plastics Italy event is scheduled for May 2025, coinciding with the Greenplast trade fair.

The process of gas substitution with air in closed cell foam with liquefied hydrocarbon gases (degassing process) is one of the most important processes, which is at the same time a "bottleneck" in the foam polymers productions. The degassing time of the foamed polymer directly affects both the final cost of the finished product and the manufacturer's responsiveness to customer orders, which is a very serious advantage in these highly competitive times.

Glycerol monostearate GMS - belongs to esters, migrates to the foam surface, reducing friction and static charges on the foam surface. Like all migrating antistatic agents, GMS accumulates moisture on the foam surface and creates a very thin greasy layer. The quality and the amount of GMS required in the formulation can significantly affect the air permeability into the polymer and increase degassing time by 10 - 15% depending on the amount introduced.

It's very important to maintain optimal temperature and humidity in the warehouse. For example, at a warehouse temperature of +25 °C the volume of air migration into physically foamed PE is on average 0,0030 grams/m2 per hour, while at a temperature of +5 °C this figure can be reduced to 0,0015 grams/m2 per hour. In southern countries with humid climates, the degassing process is usually faster, but it also often leads to rupture and collapse of the gas structural element.

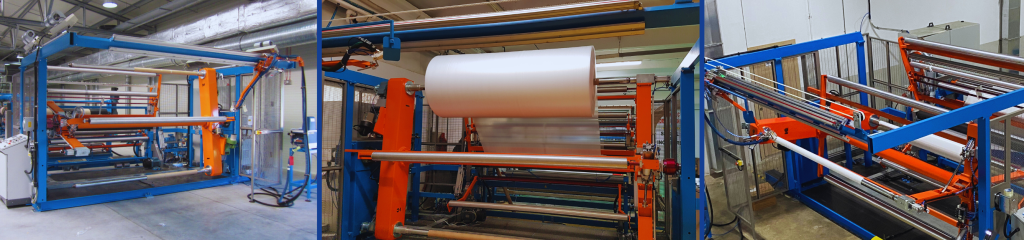

Unfortunately, there is no complete understanding of how important correct winding technology is in foam productions. In the process of winding roll, it is important to ensure that the foam tension does not depend on the diameter of the roll and that the core of the roll is not compressed. This is a very big problem for simple type winders. For this reason, each FAP winder is equipped with the so-called "Soft Winding System". This is a smart winding system that controls the equal tension of the winding rod for each running meter of material without creating a tightening effect on the core of the roll.

The creation of a small air gap between each wound meter of foam material allows to achieve a gas exchange air permeability of 0,0023 grams/m2 per hour even in the core of the roll, which is on average 0,0009 grams/m2 per hour more or 39% more than without "Soft Winding System" (calculations done at a temperature of +18 °C).

FAP is a dynamic second-generation family-run company with over 37 years of international experience in the design and construction of foam machinery and R&D activity to create for our customers something truly valuable and capable of raising the production of foamed polymers to a completely different level.

In this regard, Borealis and FAP set out to make low-density EPP foam applications that are more easily recyclable. The performance properties that have ensured the popularity of polymer foams would have to be maintained – or even improved. By leveraging their expertise in polypropylene resins and foaming technology, respectively, the partners aimed to improve physical foaming processes in order to offer innovative material solutions that are affordable, resource efficient, and more environmentally compatible.

Nowadays, the technology of extrusion of physically foamed branched polypropylene, which is still little known to the markets, is of great interest. Light weight, strong, thermoformable, 100% recyclable with excellent insulation properties. These and other characteristics have made it the unique material that can replace most traditional polymer materials in markets such as insulation in the automotive industry, heat and sound insulation in construction, and the food industry.

By leveraging the wide-ranging expertise in PP foaming technology, we improve physical foaming processes in order to offer innovative material solutions that are affordable, resource efficient, and more environmentally compatible.

Extrusion has been recognized as the most common foaming technology. Branched PP is a crystalline material with high melt strength compared to low-density PE and has technological differences in production.

Production of ultra-low physically foamed polypropylene (<25 kg/m3) and thickness from 1 to 10 mm with high quality characteristics is possible exclusively with a hydrocarbon foaming agent (such as isobutane or n-butane) and using twin-screw foam extrusion technology, which will create a certain pressure and melt speed to dissolve gas into the polymer even at high temperatures melting required for polypropylene processing. Inert gases can also be used in extrusion foaming, like supercritical nitrogen (N2) or carbon dioxide (CO2) for production of higher density foams of 150 kg/m3 or more. Non-combustible CO2 reduces the industrial hazard class in the physical foaming process, it is easier to store, and fairly inexpensive.

In contrast to conventional PP, WB140HMS offers a combination of high melt strength and low melt viscosity due to the shear thinning effect caused by the branch structure. Its excellent foamability and consistency are complemented by its easy processing. This further enhances the efficiency of the closed-loop production of PP foam: all material waste generated during production is immediately turned back into granules and fed back into the process, thereby reducing the use of virgin raw materials – with no compromise in mechanical performance.

Having tested the use of CO2 as a foaming agent in the laboratory for many years, FAP was able to develop a new machine to foam EPP using CO2, where the screws are designed in such a way as to maintain the necessary pressure in the gas injection zone at high temperatures. Further tests led to the development of a unique extrusion head and dies allowing to obtain high quality cellular structure of the foam and much better control over the expansion and crystallization of the polymer after leaving the extrusion head.

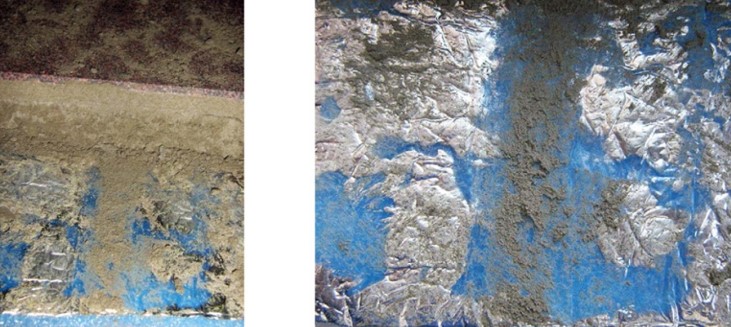

Due to the annual increase in logistics costs, the company was no longer able to purchase high-quality foil and metallized BOPP film from the European Union. Since the company was very focused on the production of polyethylene (EPE) and polypropylene (EPP) foam insulation with metallized BOPP film sheet lamination, it was imperative to find alternative materials and the only one supply option was China. The main problem was that the thickness of the cast polymer layer of BOPP film and aluminum foil was 2.5 times thinner than before. Chinese suppliers simply did not want to produce material exclusively for our customer's needs, since the volumes were not enough.

In this regard, our client asked us for support in developing new technological processes associated with the production of laminated thermal insulation from polyethylene and polypropylene foam in order to minimize the risks of foil and metallized film peeling off polymer foam after lamination.

We understood that simply changing lamination technological parameters would not help in this situation, since the problem lies solely in the quality and characteristics of the foil and metallized film used.

It was decided to work on increasing the adhesion of foam to foil and metallized film, as well as slightly change the recipe of the raw materials of the extrusion process in order to increase the gas permeability of the foam polymer and reduce the amount of residual gas in the cells of the foam polymer during the lamination process.

Firstly, we conducted an audit of technological processes, the raw materials and additives used.

The actual degassing period of the material was determined by observing changes in weight, density, and expansion of the material over several weeks at various temperatures and other conditions.

It has also been established that the quality department does not pay attention to the actual time of degassing of finished products and semifinished products and that EPE and EPP foam are often used before the actual time of replacement of gas with air, which also affects the formation of defects during lamination, since there is a large amount of residual gas during the heating process, expands between layers and prevents adhesion between films and foam.

Another feature of this project was revealed, that the customer could not afford to increase the current degassing period of foam materials due to limited storage space.

We drew up a plan for modifying the recipe with calculations of costs. It was planned to replace the standard GMS lubricant with another sliding additive in order to increase gas permeability and reduce the degassing time to no more than 10 days. It was also decided to introduce a polar copolymer of ethylene and butyl acrylate into the formulation of foamed polymers to increase the adhesion of foam materials when heated during the lamination process.

FAP teams completely took over the process of searching for suppliers of raw materials, carried out a regulated process of testing and introducing new types of raw materials into the recipe. Training materials were also prepared in the form of presentations for operators, technicians and the quality department managers, which contained detailed theoretical material on the foaming process and the influence of existing and new types of raw materials on the process. A meeting and training of all personnel was organized for 1 working day with production stopped.

By introducing new raw materials into the recipe, it was possible to bring the degassing period of foam closer to 11 days, which satisfied the customer.

In addition, the introduction of a polar copolymer increased the adhesion of foam during lamination, since the initial melting temperature of the copolymer is 12 degrees lower than the melting temperature of low-density polyethylene.

Incorporating a small percentage of this material into the formulation created a more sticky layer on the surface of the foam when heated, but the production cost of the foam polymer increased slightly. Because the film's polymer coating layer was thinner, the current cost of purchasing metallized BOPP film and aluminum foil was significantly lower than before, about 40%, making the final product more economical despite the formulation changes.

Because increasing the speed of customer order fulfillment means increased productivity and margins.

It takes knowledge and a lot of field experience. In our 37 years of work in the field of polyethylene and expanded polypropylene, we have learned to recognize, predict and eliminate every possible bottleneck in the production process.

In the production of expanded polyethylene and polypropylene, the main limitation is usually faced during "Degassing": the phase in which gas is replaced by air. This process has a significant impact on further processes, e.g. at the lamination stage: it is impossible to start the process if degassing has not been completed, and it also has a significant impact on product storage costs.

- Acceleration of delivery times: reduction of process waste in production = reduction of production batches to minimum cost-effective size.

- Optimising logistics: reducing the number of finished and semi-finished products in stock = increasing the turnover rate.

- Optimising production costs with FAP technology.

The technological and technical features of FAP extrusion lines are designed to increase the performance of the company's whole production system, including storage costs, raw material costs, and workforce productivity.

The amount of “saved” profit of the company directly depends on an effectively built quality control system and technological processes in the production of foamed polyethylene and polypropylene. The quality service department and qualified process engineers in a company engaged in the production of products from foamed polymers are in no way inferior in importance to other departments, such as the production department or the sales department.

The quality service is a controller independent of production indicators, ensuring the predictability of the work of the production unit and compliance with established indicators. Yes, the productivity and efficiency of a production unit is considered by the volume of quality products shipped that meet all stated requirements, and not by the speed and volume of products arriving from production to the warehouse.

Have you ever wondered how much 1 m2 of defective products costs a company?

For example, the cost of producing 1 m2 of scrap polyethylene foam (PE foam) 5 mm thick (20 kg/m3), processed into secondary raw materials, will cost the company approximately 0.2 euro/m2, and the cost of producing scrap 10 mm thick is approximately 0.43 euro/m2.

Based on this, the cost of 1 kg of defective polyethylene foam (PE foam) products processed into secondary raw materials will cost the company approximately 2.23 euro, which is on average 55% more expensive than the cost of 1 kg of the mixture primary (raw materials and technological additives) in the standard production recipe, foamed polyethylene 5-10 mm thick with a density of 20 kg/m3.

In addition, manufacturing defects have a significant impact on the productivity of the production unit as a whole, as unplanned “overproduction” becomes necessary.

The production of foamed polymers is no exception to the rule, and there are also mandatory criteria for monitoring technological processes, both during the production process and during storage of products, which minimizes the risk of receiving defective finished products. Unfortunately, many companies put this aside because they mistakenly believe that it does not impact the overall performance of the company that critically.

Our Italian Foam Center will help you answer these questions and organize all technological and production processes for the production of foamed polyethylene and polypropylene.

Undoubtedly, the technology of physically foamed non-cross-linked polyethylene and polypropylene is an ideal polymer production technology from a closed-loop point of view, but it is still much more profitable to work with minimal risks of receiving defective products.

OUR TEAM IS ABLE TO:

- identify and solve bottlenecks in production, increasing speed and productivity;

- optimize process parameters to reduce waste and improve product quality;

- implement best practices and advanced technologies to maximize efficiency;

- reduce raw material and energy consumption through an optimized process;

- reduce maintenance and downtime costs;

- improve product quality control, resulting in reduced rework and scrap costs;

- optimize foam properties according to customer specifications;

- support new product development and optimization of existing products;

- provide access to industry-specific knowledge and expertise;

- take advantage of the latest technologies and innovations;

- develop internal skills and staff training;

- promote awareness of production processes and their interdependencies.

He was always passionate about his Foam Machines, cared for and controlled down to the last detail. He was always present with customers during the Start-up of his foam lines because he considered them as his own children whom he accompanied on the greatest adventures to conquer the world's markets.

Today, the legacy lives on through Luigi's sons, Francesco Poli and Fabrizio Poli, who are actively steering the company towards international success. The FAP team, comprising skilled professionals, plays a pivotal role in elevating the company to new heights.

The passion and dedication inherited from Luigi are evident in every project undertaken by sons, and the entire FAP team. As they continue to build on their father's vision, FAP is not merely a company; it's a testament to the enduring spirit of innovation, creaftsmanship, and familialbonds.

Luigi's memory lives on, not just in the machines that bear his imprint, but in the thriving international presence that FAP is becoming, thanks to the collaborative efforts of the next generation and entire team.

January 12, 2024

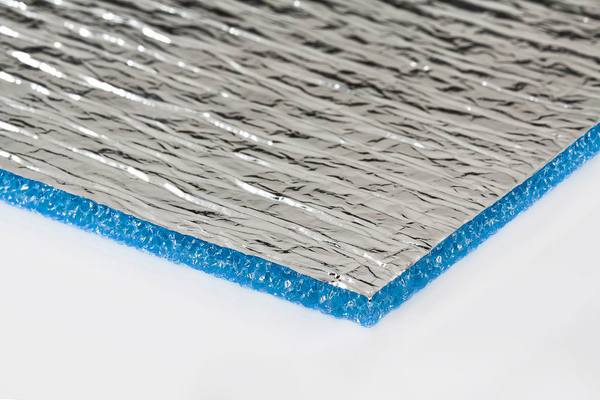

The use of foamed polymers is extremely versatile, but the main thing is that all necessary technical requirements are met, specially in construction industry and as a striking example is a reflective insulation. Manufacturers of foamed polymers need to create materials that educate the final user, do not mislead him when choosing products for construction and repair, to force unscrupulous manufacturers to change their approach to production and product quality.

We all want to live in comfort and very often during construction or repair we install a “warm floor” system in our homes. Today, FAP would like to talk about the use of foamed polypropylene and polyethylene in this constructions.

What is reflective insulation for? How can a foam manufacturer not disappoint his customers? Can aluminium foil be used without a protective layer of transparent polymer in construction?

There are some reasons:

• Local overheating of the screed. As you know, the principle of operation of a "warm floor" system is quite simple. Heat from the heating element (water pipes or electric heaters) is transferred to the concrete screed, the concrete screed heats up and heats the coating on it.

It is the reflective layer of aluminum foil that contributes to the uniform heating of the screed and the floor covering, since the thermal conductivity of the foil is about 150-180 times higher than that of concrete and the foil heats up very quickly, evenly distributes heat over the entire space of concrete, without creating local overheating of the floor. The absence of aluminum foil as a reflective layer can cause that in some areas of the floor the heating element warms up much faster and absorb more heat, while in other areas there is no direct contact with the heating element. Ultimately, this can lead to cracking of the concrete screed.

• Reduced heat loss of the “warm floor” construction. PE or PP foam insulates the entire structure, preventing the heat goes down, since the coefficient of thermal conductivity of PE and PP foam with a thickness of 4-5 mm and a density of 25-30 kg/m3 is about 0.035 - 0.038 W/m2, which is approximately 1.5-2 times lower than that of concrete.

Many people mistakenly believe that it is the reflective foil that prevents the passage of heat down, acting as an insulator, but this is not correct. Unfortunately, even builders who have no idea about the principle of this action use only one aluminium foil as insulator without foamed polymer layer. As explained before, the thermal conductivity of aluminum foil is very high and it cannot be used as an insulator without having an air gap underneath, which is foam. Anyone who responsibly attended physics lessons at school has already understood that the foil fulfills exclusively the principle of convection and radiation.

Thus, the use of PE & PP foam with a reflective foil layer with a thickness of only 25-30 microns will significantly increase the efficiency of the "warm floor" system, reduce the heating time of the concrete screed and reduce heat loss.

The fact is that the reaction of an alkaline solution (cement) with aluminum leads to its destruction due to the displacement of hydrogen. After a while, the foil will simply dissolve and only the foamed polymer will remain. For this reason, there will no longer be a uniform distribution of heat over the concrete screed, which can lead to local overheating and cracks. Therefore, it is extremely important to use a foil with a protective polymer layer on the reflective side in the lamination of foamed polypropylene or polyethylene, since the protective polymer layer will not allow the reaction between the foil and the alkaline solution.

We are waiting for you at Plast Eurasia 2023

Come and visit Stand 11A-101 / 📅 22-25 November 2023

Our local agent Baris Argaman & Sales Director of FAP Francesco Poli will be available to present you our cutting-edge technology for foam production, converting by FAP & VELA by FAP, will tell about 𝗮𝗱𝘃𝗮𝗻𝘁𝗮𝗴𝗲𝘀 𝗮𝗻𝗱 𝗴𝗿𝗲𝗮𝘁 𝗽𝗲𝗿𝗳𝗼𝗿𝗺𝗮𝗻𝗰𝗲 𝗼𝗳 𝗼𝘂𝗿 𝗹𝗶𝗻𝗲𝘀, 𝗲𝗾𝘂𝗶𝗽𝗺𝗲𝗻𝘁 𝗮𝗻𝗱 𝘂𝗻𝗶𝗾𝘂𝗲 𝘀𝗲𝗿𝘃𝗶𝗰𝗲𝘀 we offer, also show the markets for foam materials often that few know about.

FAP, Your Foam Extrusion Partner 🌎

FAP team wishes all participants fruitful and efficient work!

FAP, a personal approach with an international vocation, since 1987.