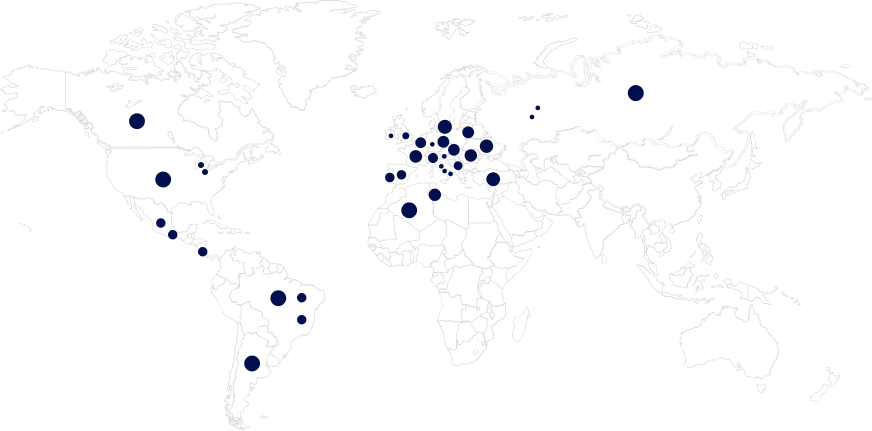

Discover Our Tailor-Made Technologies for Your Production From October 8 to 15, we’ll be in Düsseldorf at K2025, the world’s leading plastics and rubber trade fair.You’ll find us at Hall 16 / Booth 16D68 – and we’d love to meet you. At K2025, FAP will present the best tailored solutions: Each project reflects our way […]

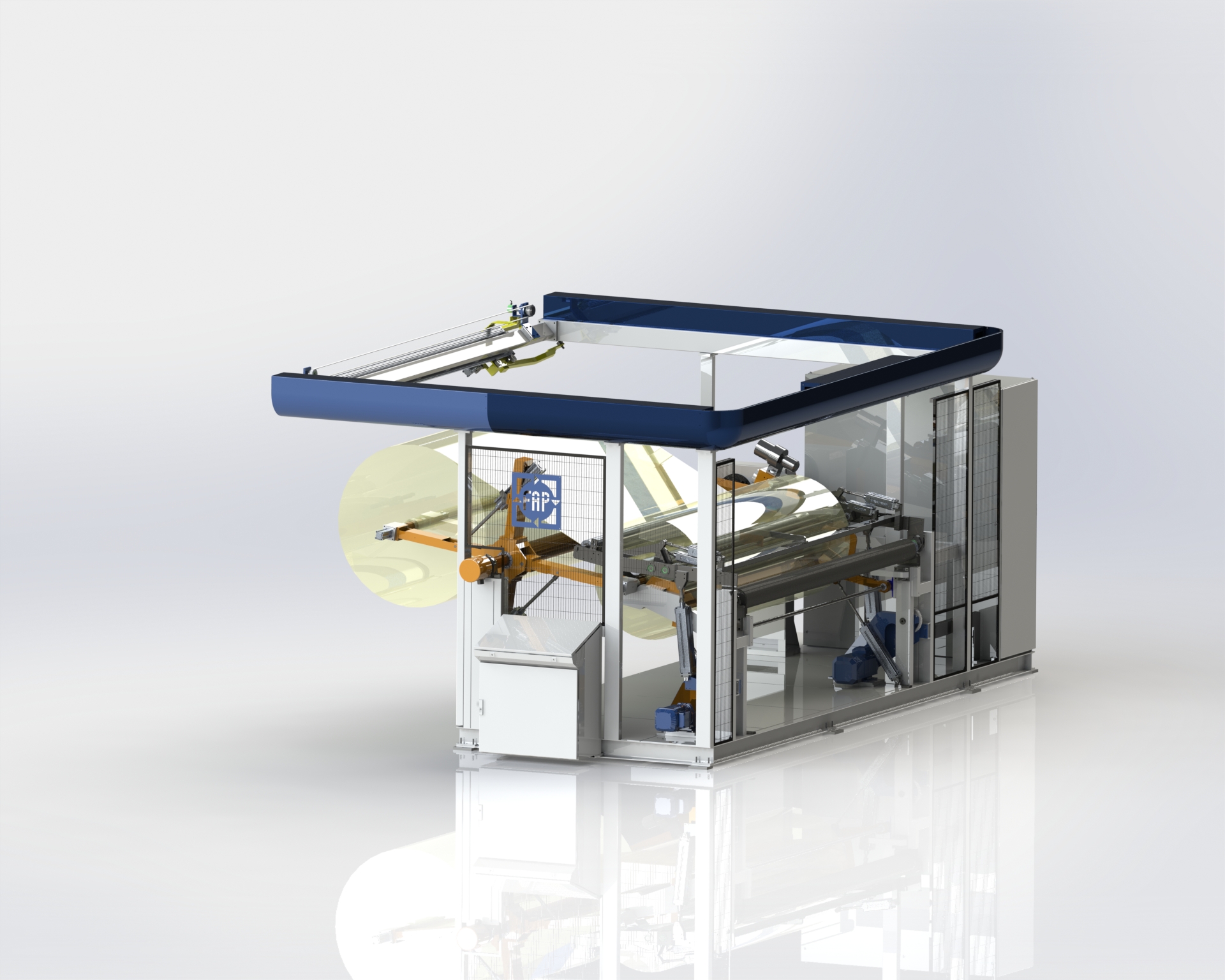

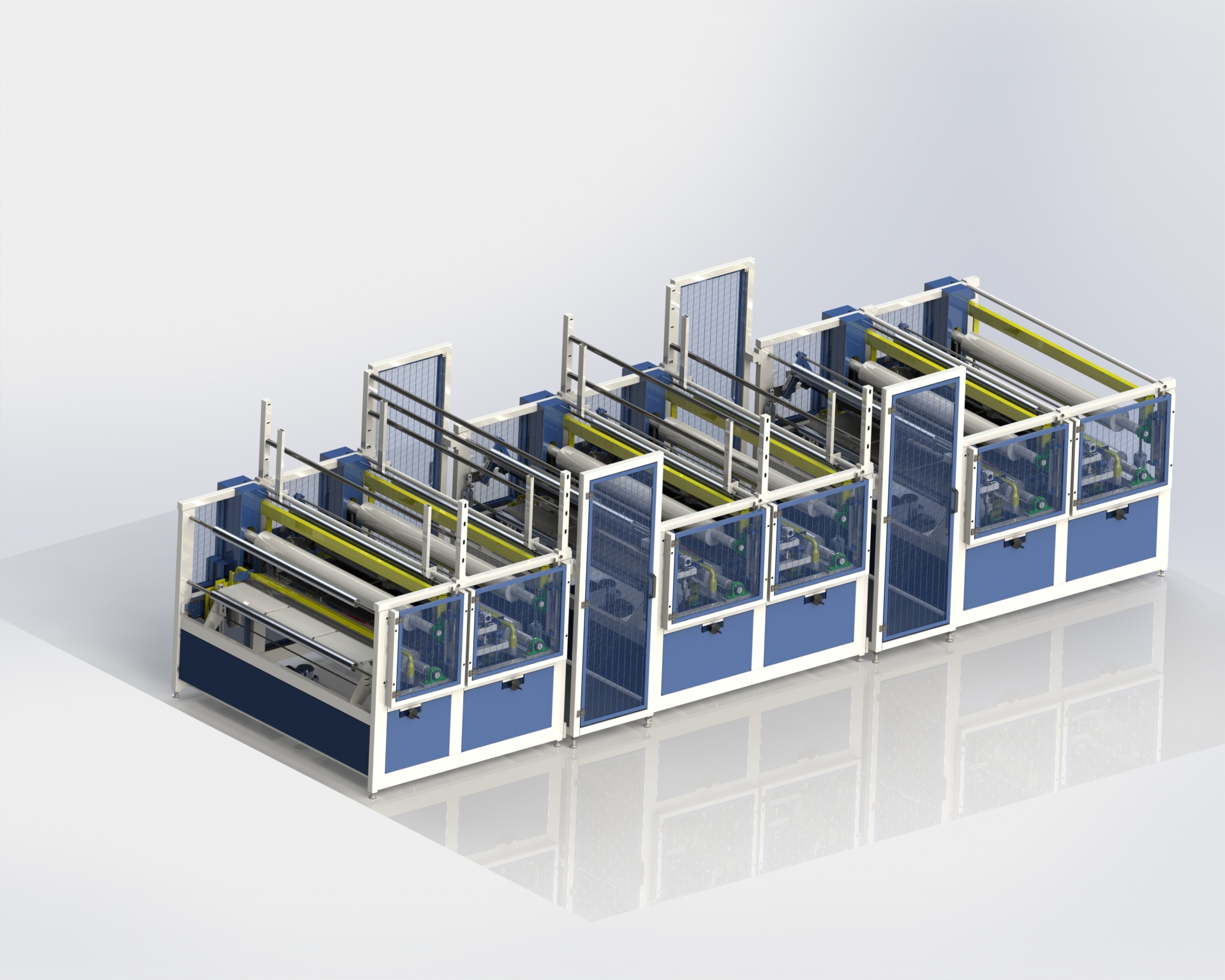

Innovative and

groundbreaking technologies

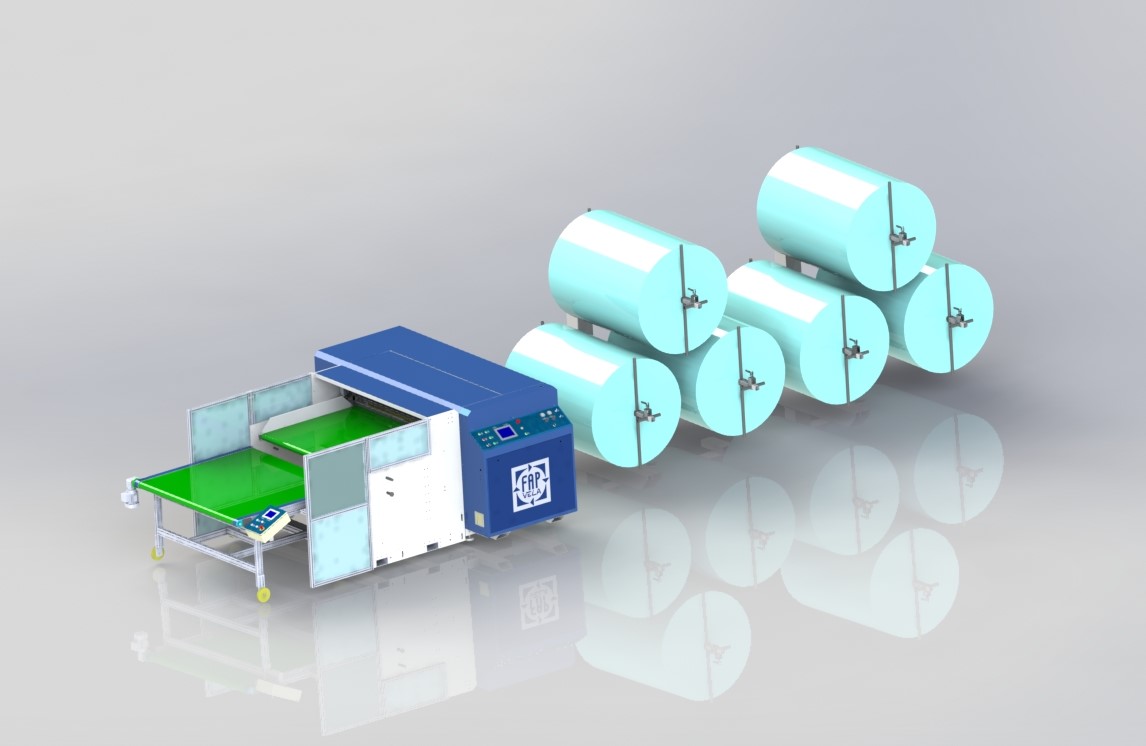

Inimitable foam quality and

excellent output rates

excellent output rates

Innovative and

groundbreaking technologies

Inimitable foam quality and

excellent output rates

excellent output rates