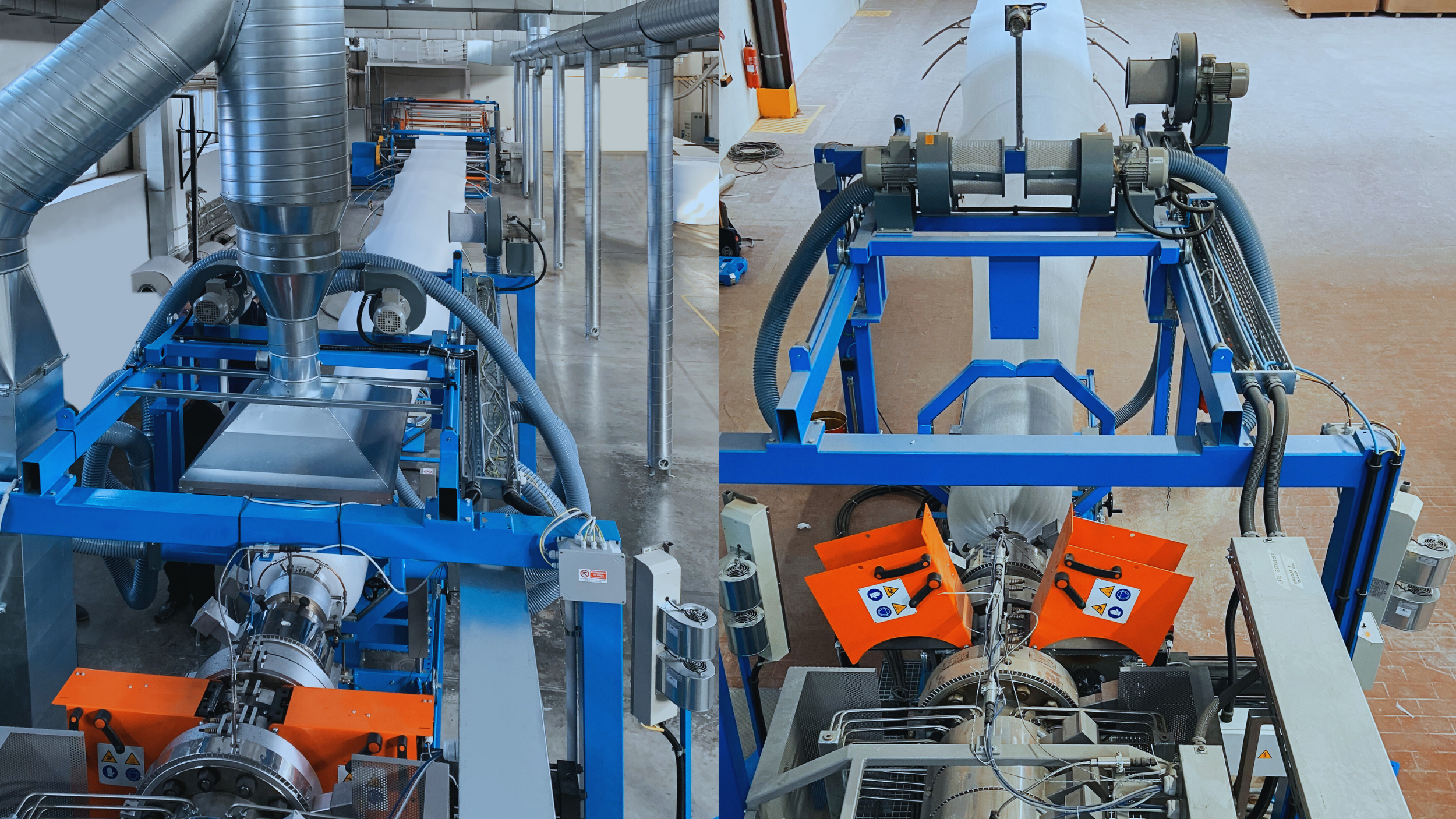

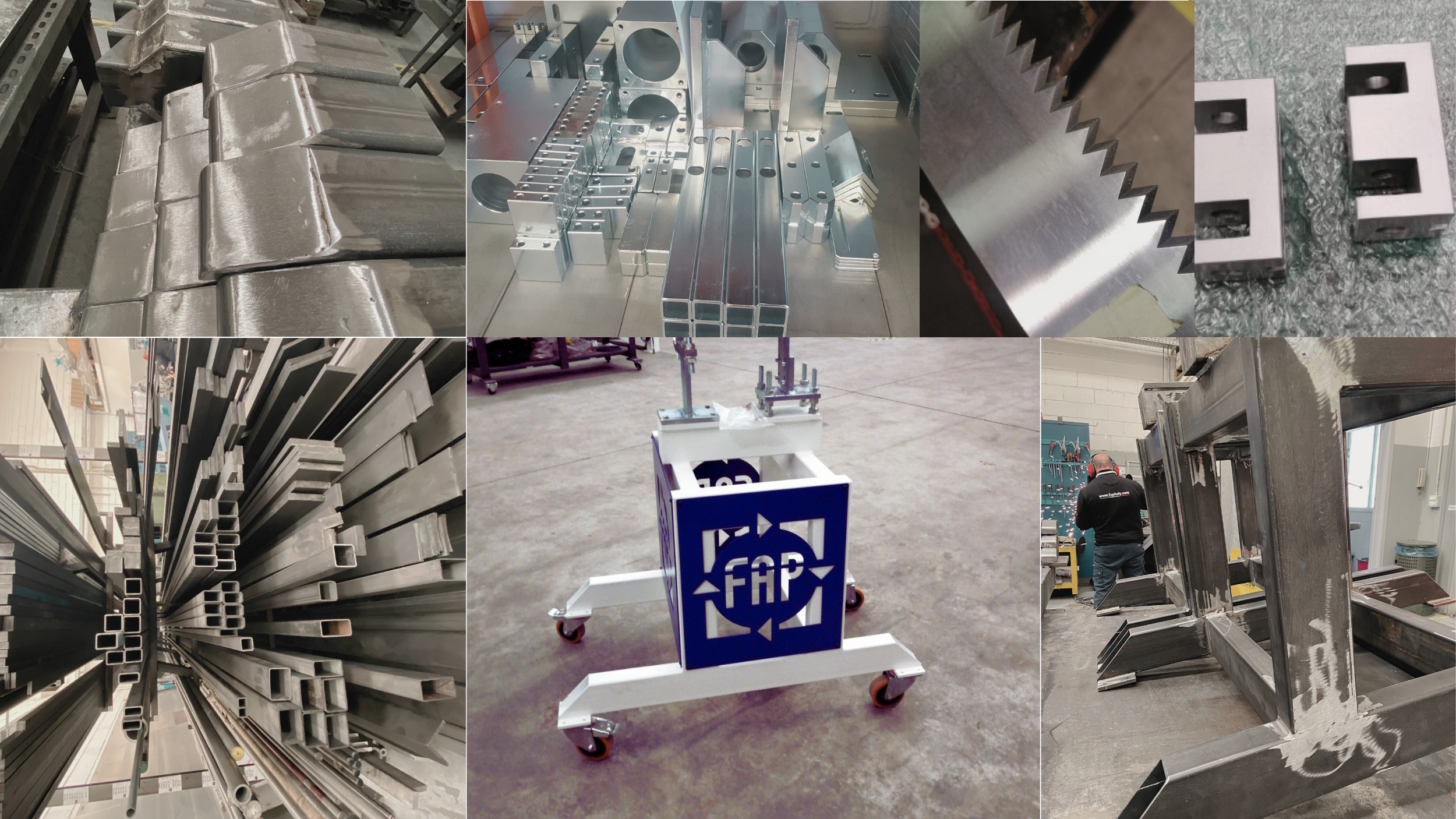

FAP presents the most flexible extruders in the market "Made in Italy", allow covering a whole range of foam productions with a single machine. FAP offers a wide range of technical high quality Polyethylene (EPE) and Polypropylene (EPP) foam extruders that allow to satisfy all production requests, ensures foam productions from 100 to 1200 kg/h with densities from 15 to 400 kg/m3 and for sheet thicknesses of Polyethylene (EPE) foam from 0,5 to 30 mm and Polypropylene (EPP) foam from 1 to 10 mm.

When deciding to invest in the production of polyethylene (EPE) and polypropylene (EPP) foam, it is important to understand: What materials do you want to produce on foam extrusion line?

Where we will give some examples of the competitive advantage of FAP foam extrusion lines with counter-rotating technology.

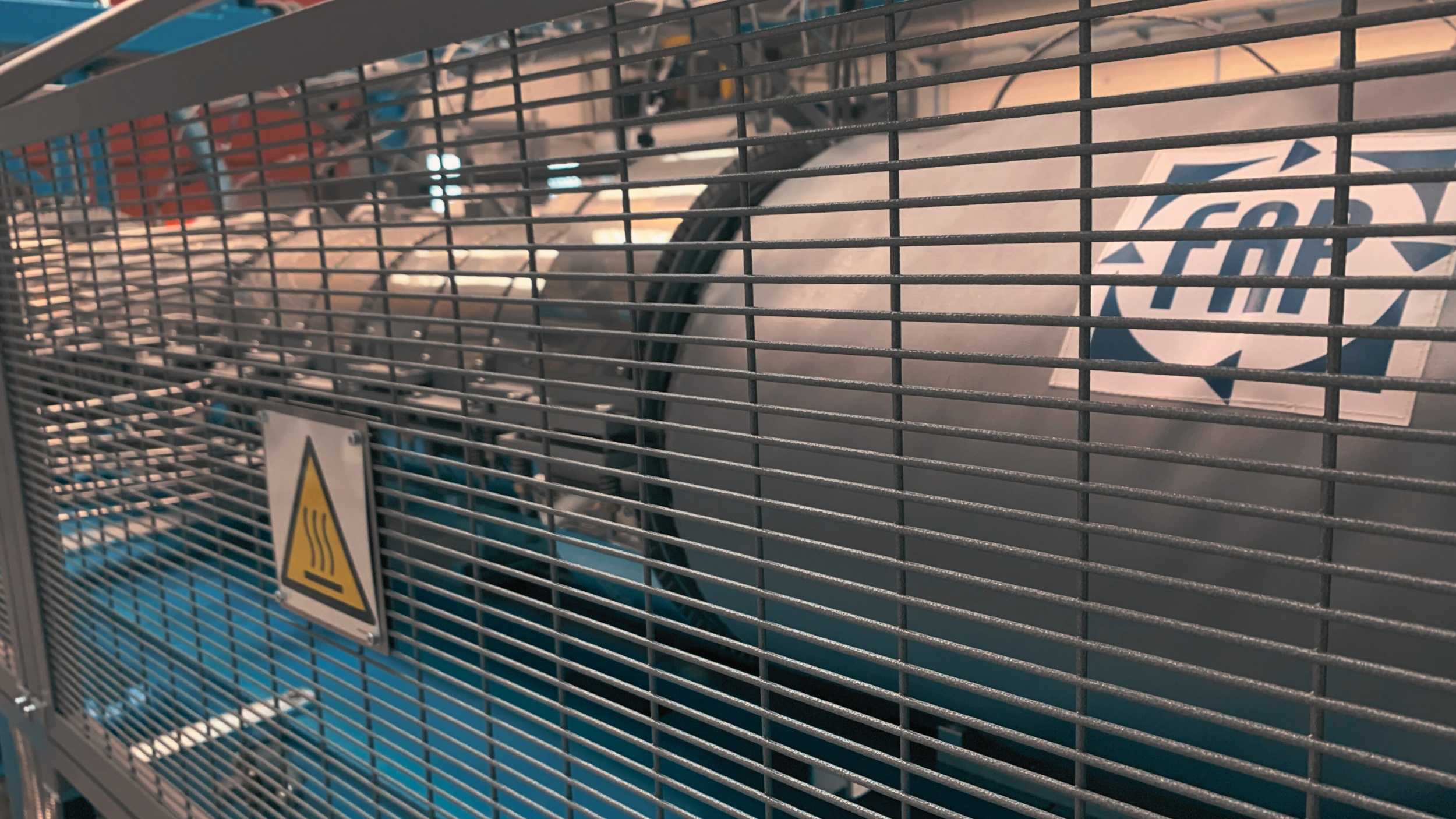

The twin-screw FAP extrusion technology ensures uniform melt and mechanical mixing of the polymer by grinding of material at the screw contact point. This positively affects technological factors such as:

The exclusive and original designing of extrusion heads has been studied by FAP for excellent control of the material and its distribution inside before the exit.

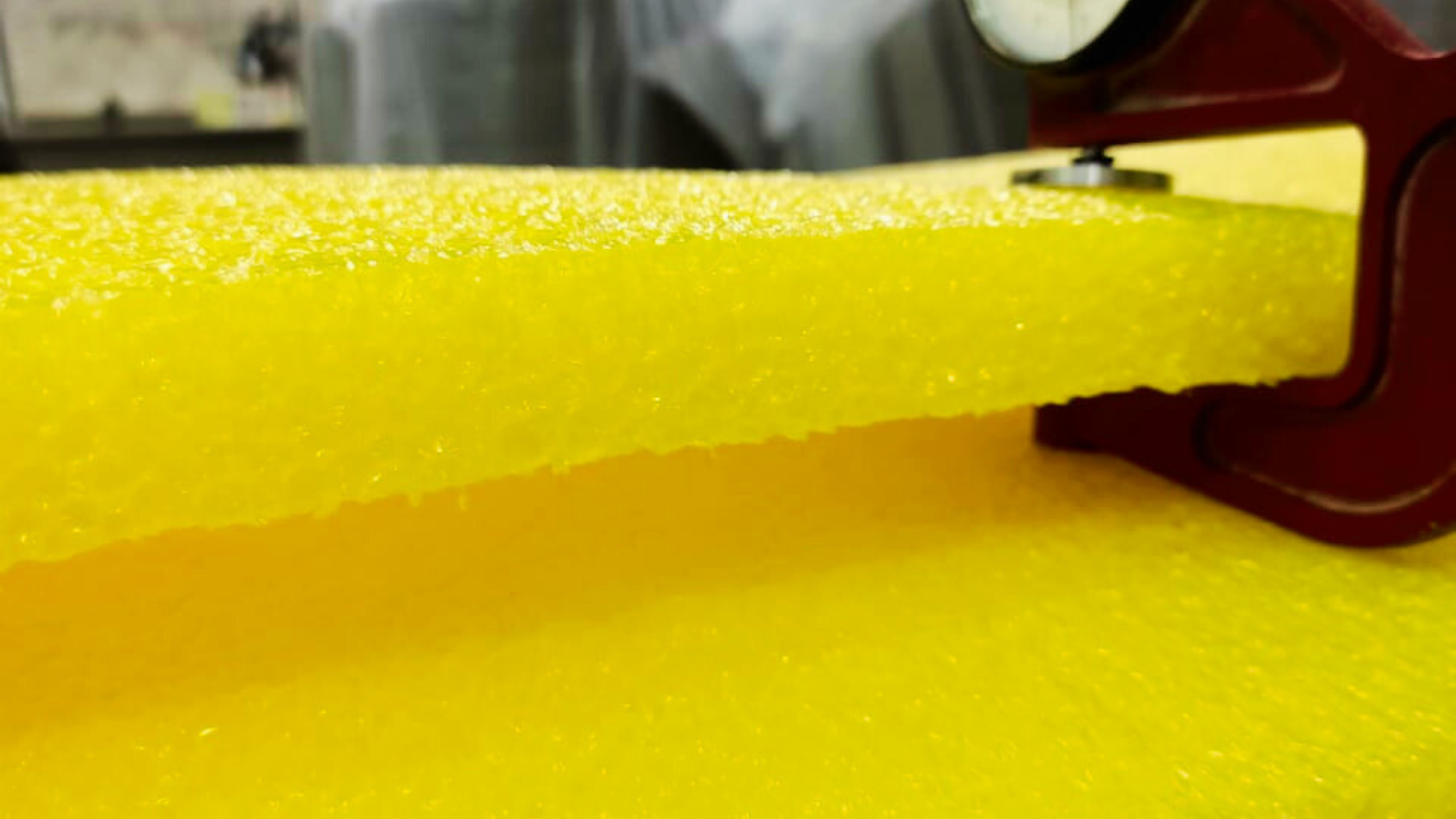

FAP has studied a specific reeling system “Soft Winding” which permits to have a full controlled tension among the reel coils, to obtain the same thickness of the internal and external spires of the roll controlling the post expansion and helping the right stabilization of the material.

The foam winders are Universal and can be installed on any foam production line