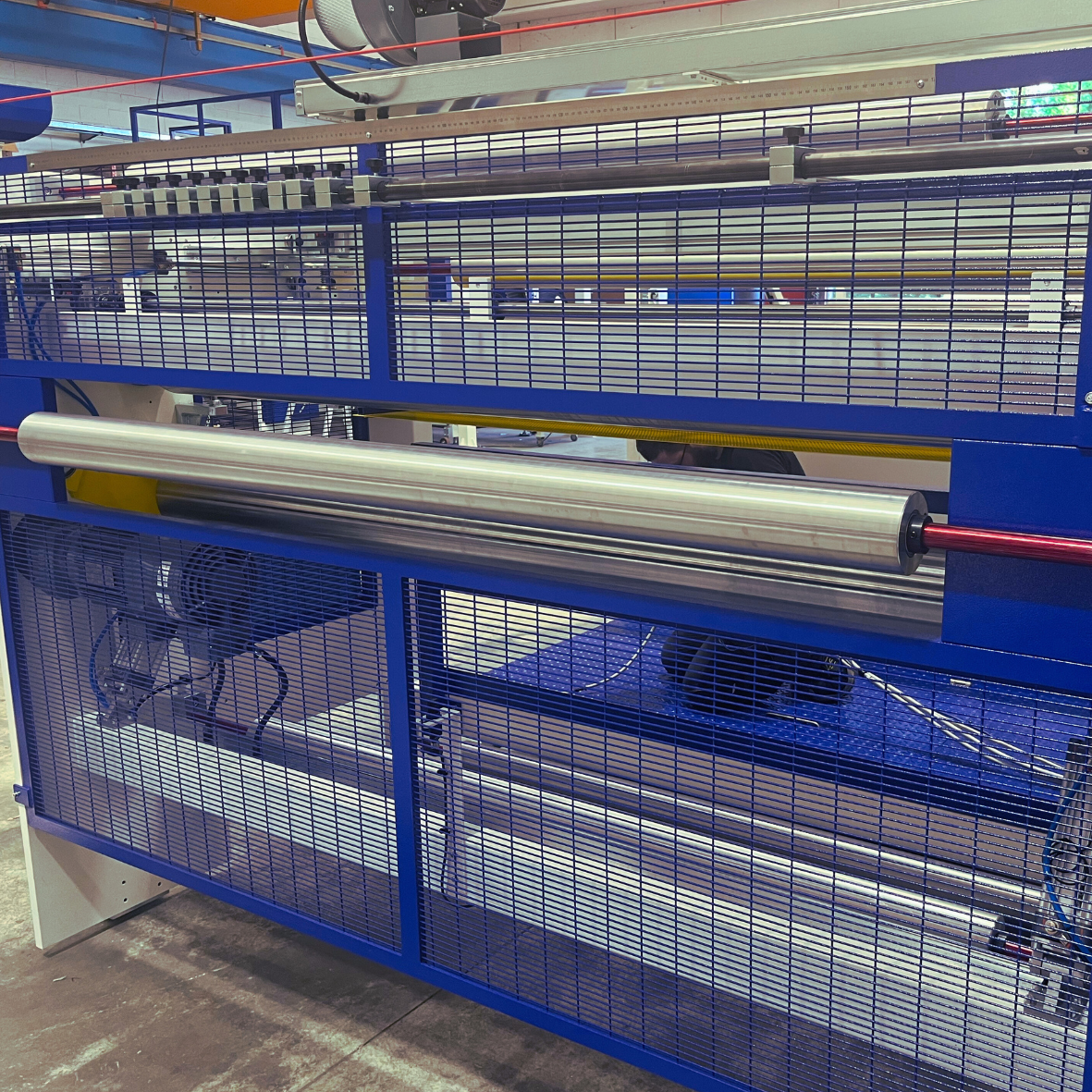

FAP designs and manufactures a complete range of inline and offline laminators that guarantee high-quality bonding across multiple materials and applications. Depending on production needs, the machines can integrate different systems available either as stand-alone units or combined for maximum flexibility.

Each laminator is engineered to deliver:

Superior adhesion between layers, even with different thicknesses and densities

Customization according to production flow, formats, and material combinations

High productivity and continuous operation, thanks to automation and modular design

FAP laminators are suitable for processing a wide variety of materials, including foam, bubble film, EVA, LDPE, HDPE, PP, metallized films, paper, aluminum, and composite structures.

The resulting laminated products are widely used in industries such as construction, packaging, automotive, civil engineering, and sports equipment, where properties like thermal insulation, acoustic performance, mechanical strength, and resilience are essential.

Custom Inline Hot Roll Laminator – Efficient and Reliable Film Lamination for Foam & Air bubble film

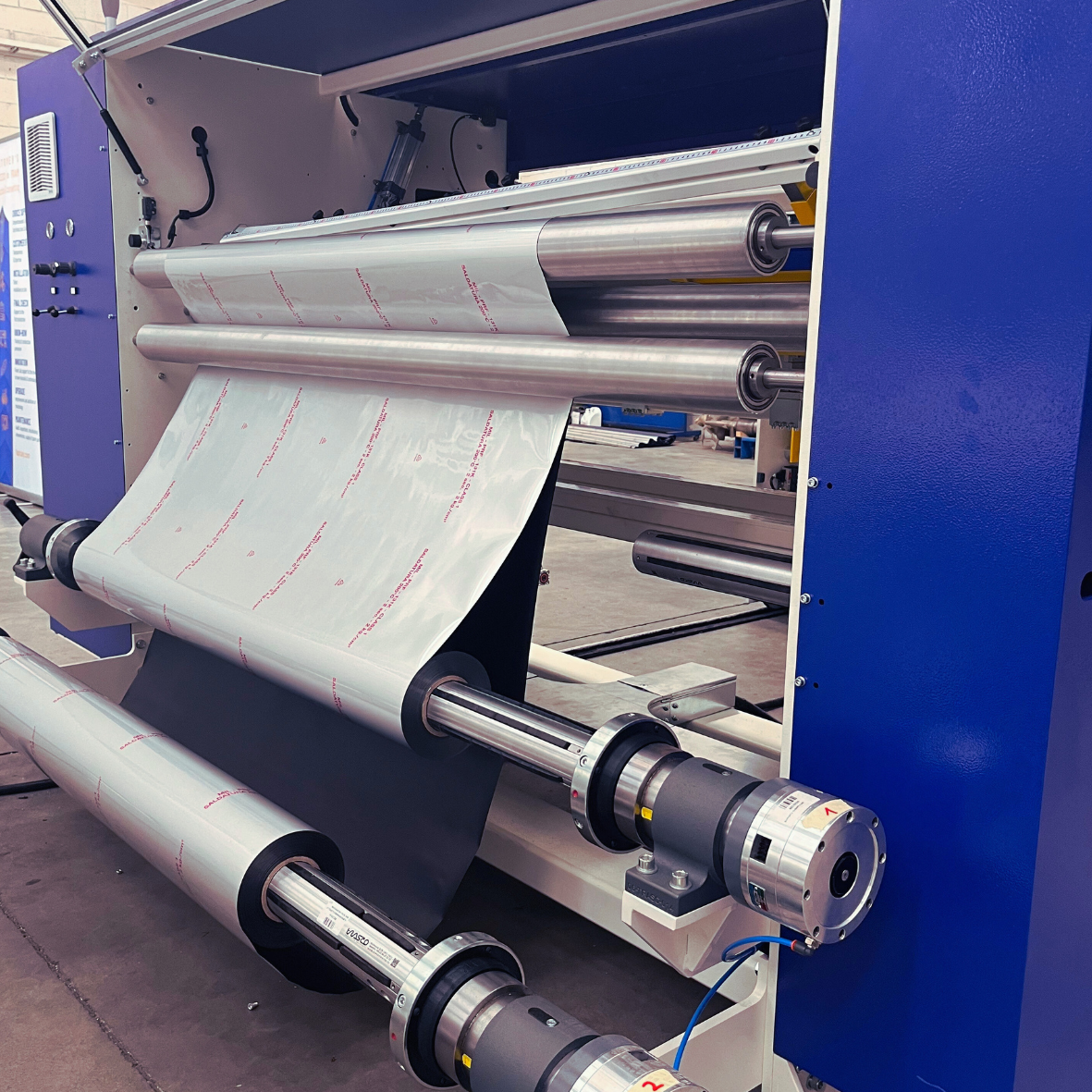

This laminator uses high-precision heated roll to bond the materials. The process ensures excellent surface contact, stable lamination results.

The Inline Foam & Air Bubble Film Laminator can also be integrated into a complete extrusion line — even retrofitted later on. Positioned directly after the extruder, it enables HDPE film lamination onto foam or bubble materials at high line speeds, supporting a continuous and efficient production process.

The structure of laminator is available in two configurations to accommodate different production layouts and material flow through the lamination head. The unwinding structure for heavy rolls also varies between: floor-mounted unwinders or mezzanine-mounted unwinders.

Possible applications: The all-round applications make foam a popular choice in e-commerce. Lamianated with film foam and air bubble film packaging protects from mechanical damage, moisture and soil. Foam has proven to be an excellent solution when covering fragile and brittle products or any goods that may be subject to scratches and breakage. Subsequently, the material can be transformed into bags and sheets.

FAP lamination systems ensure superior bonding quality even on materials with different thicknesses and densities, delivering maximum reliability and consistency in every process. They represent the ideal solution for manufacturers of plastic and foam materials looking for precision, flexibility, and high-efficiency lamination.

Each lamination line is an independent machine designed to uniformly laminate foam of various thicknesses with a wide range of covering materials on one side, including films, foils, or special substrates.

To further increase productivity, the system can be upgraded with dedicated automation modules, enabling non-stop production and reducing downtime to a minimum. This makes FAP lamination machines the perfect choice for companies aiming to combine high output, product quality, and production efficiency.

Possible applications: As a versatile insulation material for various applications in the construction industry: heavy-duty floor mat for excellent sound insulation and vapor barrier / universal sound and heat insulating material with a reflective effect (PE foam laminated with a metallized lavsan film) / vibration-insulating material with a waterproofing layer (PP foam laminated with waterproof polymer film).

The FAP multilayer laminating machine is specifically designed to simultaneously laminate up to 6 layers of foam with different densities and high thicknesses, making it the ideal solution for plank and board production.

Thanks to its advanced Hot Air lamination technology, the machine ensures perfect bonding of multiple foam sheets or EVA layers, creating strong, resilient, and elastic planks with excellent structural properties.

These laminated foam planks are suitable for a wide range of high-performance applications, including:

Protective packaging for delicate or heavy products

Construction industry, for insulation and structural components

Sports equipment, requiring shock absorption, flexibility, and durability

By combining flexibility in materials, multi-layer capability, and high-thickness processing, FAP multilayer laminating machines guarantee superior product quality and high-efficiency production for manufacturers looking to expand their foam applications.

The FAP Hot Blade Laminator is a custom-designed solution developed for companies that require versatile lamination of thermoplastic materials and unique production setups. Using controlled heat, this system ensures strong and reliable bonding without the need for adhesives or glues.

Operating as an offline machine, it employs a high-efficiency hot blade system that bonds layers through heat only. Thanks to precise thermal control and robust mechanical design, it can laminate a wide range of materials, even with different densities, thicknesses, and properties.

The laminator’s modular structure allows full customization of both the lamination section and the material handling systems, ensuring seamless integration with each client’s production flow, formats, and material types. Whether the requirement is to laminate foams, films, or complex composites, this technology adapts to the specific process.

Ideal applications across industries:

Protective packaging

Automotive

Building & construction

Civil engineering

Sporting goods

With FAP hot blade lamination technology, manufacturers can achieve clean, durable bonding across multiple layers, even between dissimilar materials, while keeping the flexibility to expand or evolve their product range over time.