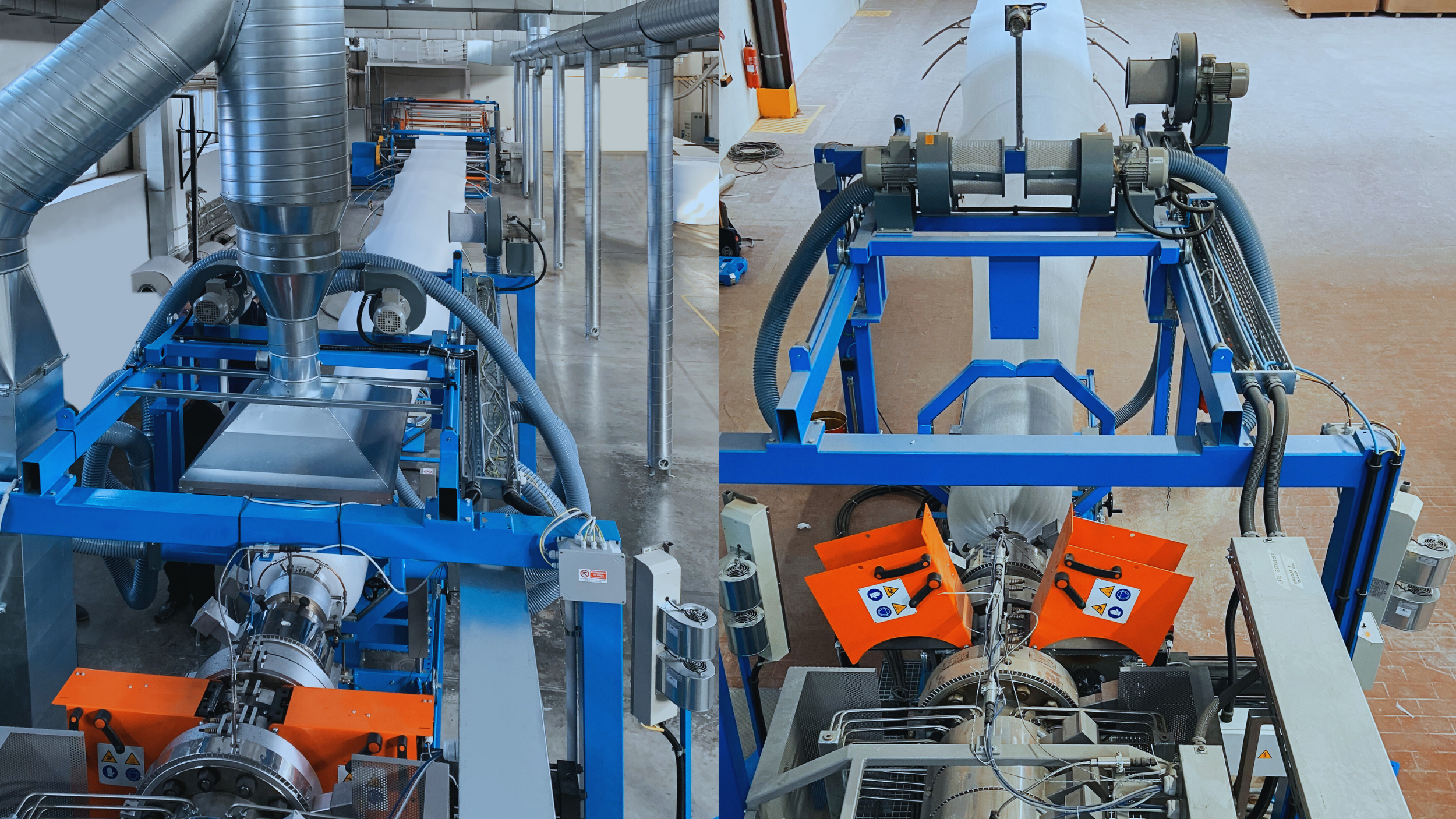

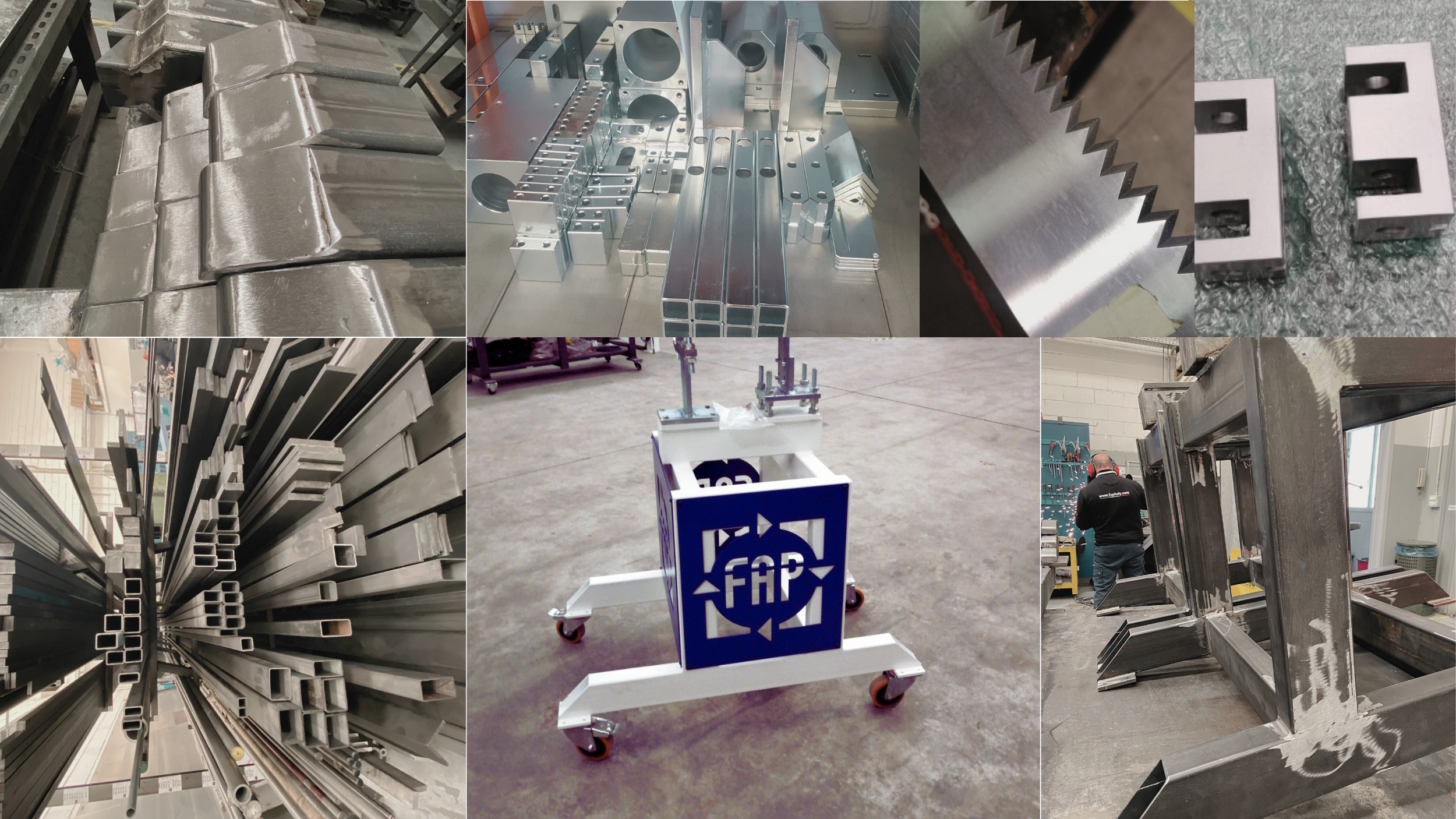

FAP designs and manufactures the most flexible and high-performance foam extrusion lines on the market. Entirely Made in Italy, our machines are built to deliver consistent quality, outstanding productivity, and full process control — from raw materials to finished rolls.

With a single FAP foam extrusion line, you can produce a wide range of expanded closed-cell foam materials, tailored for multiple applications and industries.

Our twin-screw extrusion technology allows for the production of:

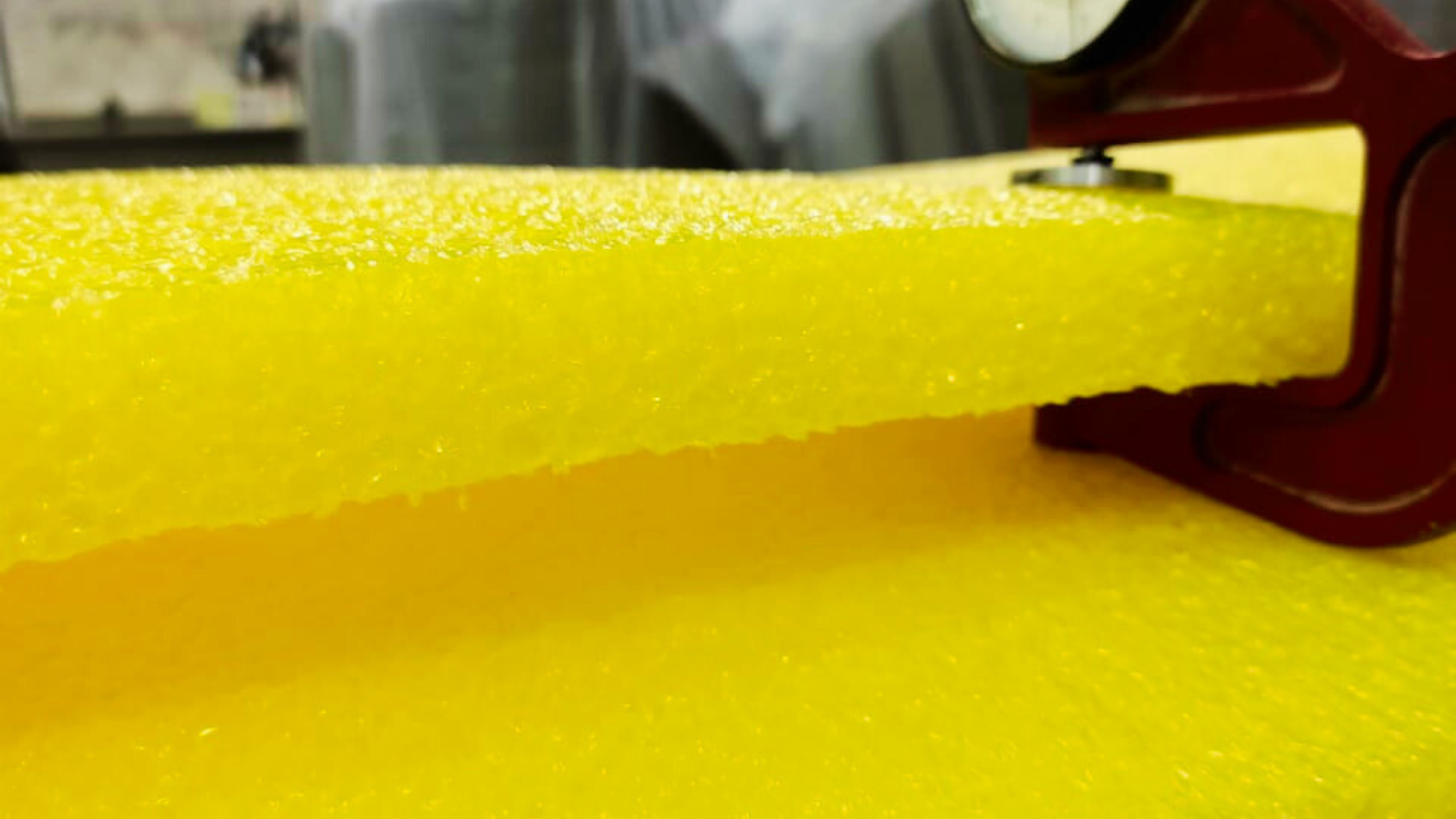

Expanded polyethylene (EPE) foam: from 0.5 to 30 mm

Expanded polypropylene (EPP) foam: from 1 to 10 mm

Foam densities ranging from 15 to 400 kg/m³

Output max. capacity of FAP extrusion lines: from 100 to 1200 kg/h

This means maximum flexibility, whether you work with thin, thick, light, or high-density foams.

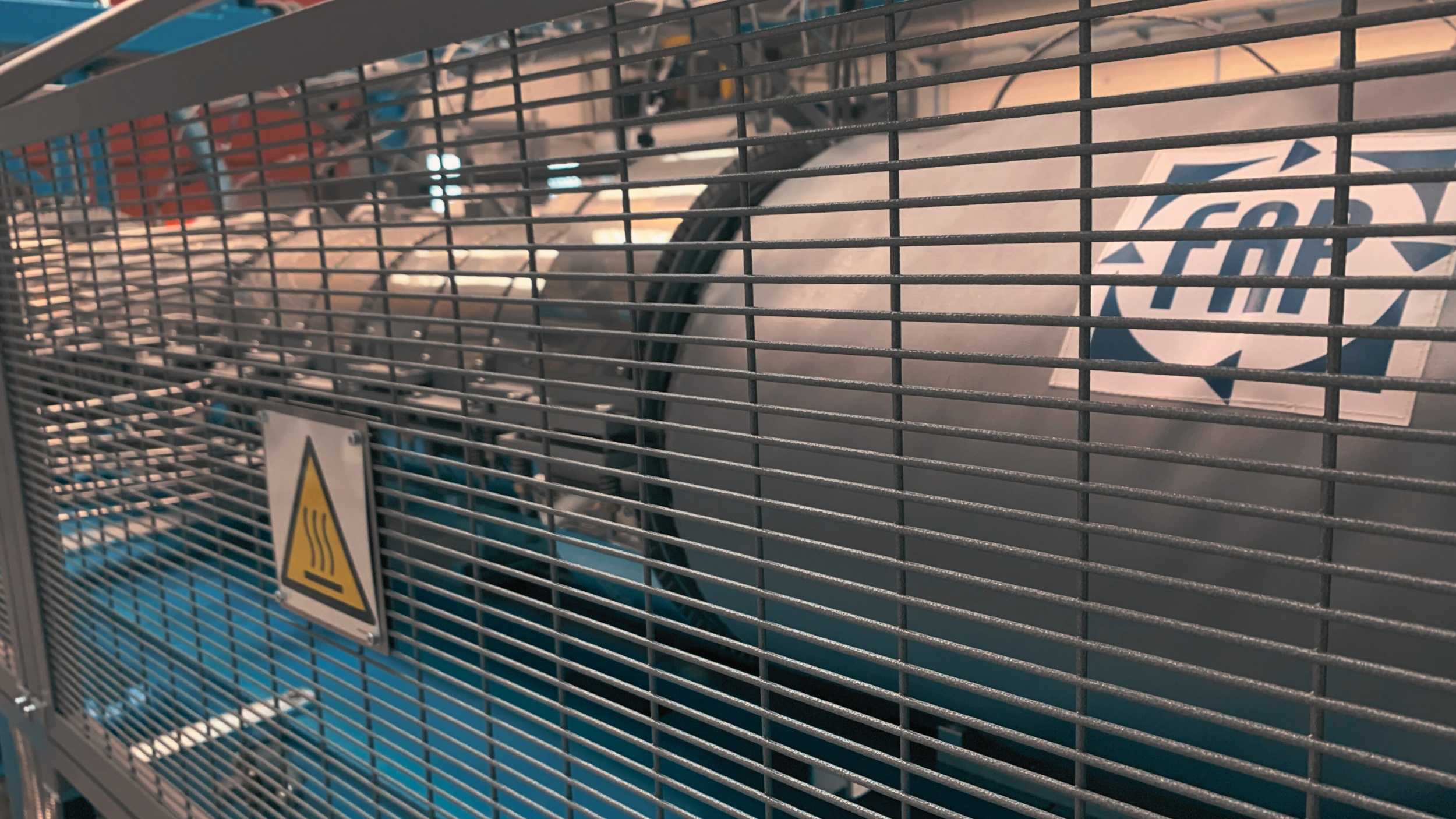

The Key competitive advantage of FAP foam twin screw extrusion lines with counter-rotating technology.

Efficient recipe switching with minimal time

Change dyes or recipes in under 5–7 minutes, minimizing waste and boosting production uptime

Reduced material loss and downtime

FAP’s custom-designed extrusion dies (extrusion heads) for thin/normal thicknesses and for thick thicknesses guarantee perfect control of material flow and thickness, from thin foam films to thick ones.

After extrusion, the tubular foam is slit, expanded and cooled on dedicated supports before winding — preserving the integrity of the foam structure while it’s still “alive.”

Our Soft Wind System was developed specifically for EPE/EPP foams. It ensures:

Controlled tension between roll layers

Uniform thickness across the entire roll

Correct post-degassing development of the foam

100% automated cutting system

Optional units: automatic core gluing, longitudinal cutting, and reel unloading

The automation of FAP foam extrusion lines can be configured in modules to include:

Real-time process visualization

Smart alerts and remote supervision

Integration with automatic winding and handling systems

Seamless recipe management and traceability