FAP is dedicated daily to the development of new solutions and innovative applications not yet present on the market, always trying to anticipate the needs of foam producers and the market. To meet the customers’ needs, and to ensure precise and complete answers, FAP has created an internal Italian Foam Centre to test granules and to produce special foam materials in little scale. During the last years numerous tests were carried out together with customers, producers of raw materials and research centers.

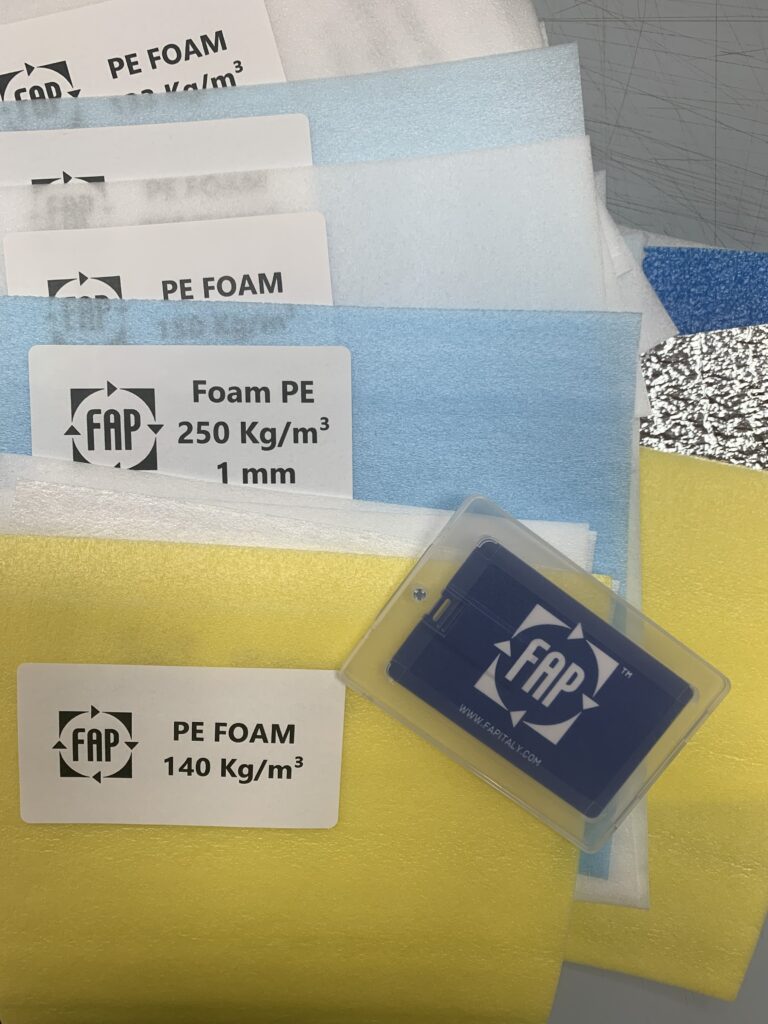

Thanks to the numerous requests in the recent months the samples of high-density polypropylene (PP) and polyethylene (PE) foam have been produced and tested, perfect for being thermoformed and laminated with the final use in various industrial sectors such as automotive, construction and food.

Furthermore, today the company is the protagonist of a courageous entrepreneurial choice. FAP invests over 5 million euros to build the site which provides the expansion of the new production area, that nowadays has become insufficient to manage the ever-increasing number of orders. Also, our Foam Centre will be expanded for research and development of expanded plastic materials in industrial scale, that has already solicited requests by companies all over the world including for example USA, Germany, Brazil, Chile, Saudi Arabia, France.

"We collaborate with companies that work, produce and study polymers: today companies have the opportunity to carry out tests in our Italian Foam Centre in little scale, but not to continue experimenting on industrial production machines”, Fabrizio Poli explains. “We build these machines and we want to share our rich experience creating a line specially dedicated for tests in industrial scale. Moreover, this center will be used by our company for the study of new materials and to improve processes in terms of energy efficiency", continues Poli, who has already established relations with the Polytechnic of Milan for the evaluation of an innovative material that FAP patented. "We are talking about a replacement of polystyrene material for the food sector with 100% recyclable foam produced using 100% natural gas CO2", Poli concludes.