Analysis of the main problems in the production of foam materials around the World.

- Low automation of production processes.

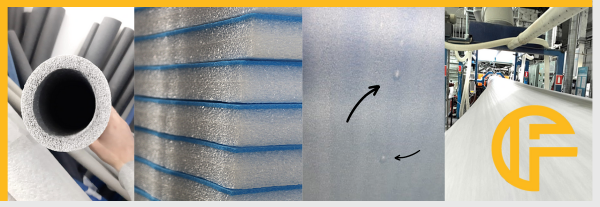

- Bubbles, foam collapse, layer delamination during lamination, a lot of defects during production line setup.

- Degassing period, low warehouse turnover, the share of logistics in the cost price can be 18-23%.

- Lack of intellectual base and resources for developing new types of products.

- Big problems with qualified personnel.

- High costs of raw materials - the share of raw materials in the cost price is from 45 to 55%, therefore any price increase significantly increases the cost price of products.

Specific solutions from FAP division Italian Foam Centre

Challenge 1 - Technological Defects and Poor Quality of Foamed Polymers?

- Destruction of the structure and bubble formation on the foam surface during degassing?

- Low adhesion of foamed polymer and peeling of layers after lamination?

- High percentage of defects per batch during extrusion?

- Low compressive strength, poor thermal stability, insufficient tensile strength, or other unmet required parameters?

Solution 1 by Italian Foam Centre:

- Optimizing production process parameters through detailed analysis and specific recommendations for each type of processing additive.

- Developing and implementing copolymers in the production formula to enhance adhesion.

- Minimizing technological defects by improving technology and production processes.

- Enhancing the physical and mechanical properties of expanded polymers to meet customer requirements.

Challenge 2 - Struggling with High Raw Material Costs?

- Looking to reduce product density without compromising production stability?

- Unsure which raw materials to select for your specific product?

- Wondering if it’s possible to produce physically foamed ultra-low-density polyethylene?

Solution 2 by Italian Foam Centre:

- Conducting in-depth analysis of raw materials and equipment to optimize production costs.

- Developing tailored raw material specifications based on the type of product being manufactured.

- Proposing advanced technological solutions for producing physically foamed polyethylene with the lowest possible density while ensuring a stable production process.

Challenge 3 - Developing New Foamed Polyethylene and Polypropylene Products?

- Need to create a product that stands out against other polymers?

- Lacking knowledge of raw material compositions?

- No access to testing facilities?

- Ready to bring your product to market?

Solution 3 by Italian Foam Centre:

- Innovating new types of expanded polymers, including the blending of different polymers to introduce new properties.

- Developing the raw material base with detailed cost analysis tailored to your technical specifications.

- Testing production processes in FAP’s dedicated laboratory.

- Evaluating the product for compliance with the required physical and mechanical properties as per technical specifications.

- Providing comprehensive marketing support to promote your product within the packaging and insulation markets.

Challenge 4 - Advanced Training for Engineers and Operators in Polymer Foam Production

- Need to enhance the skills of your production team in polymer foam manufacturing?

- Looking to reduce human error rates in production?

Solution 4 by Italian Foam Centre:

- Developing comprehensive training materials for an in-depth understanding of physical foaming

- Organizing and conducting practical, hands-on technological training directly at your production site.

- Creating process documentation and operating procedures that align with the quality management system.