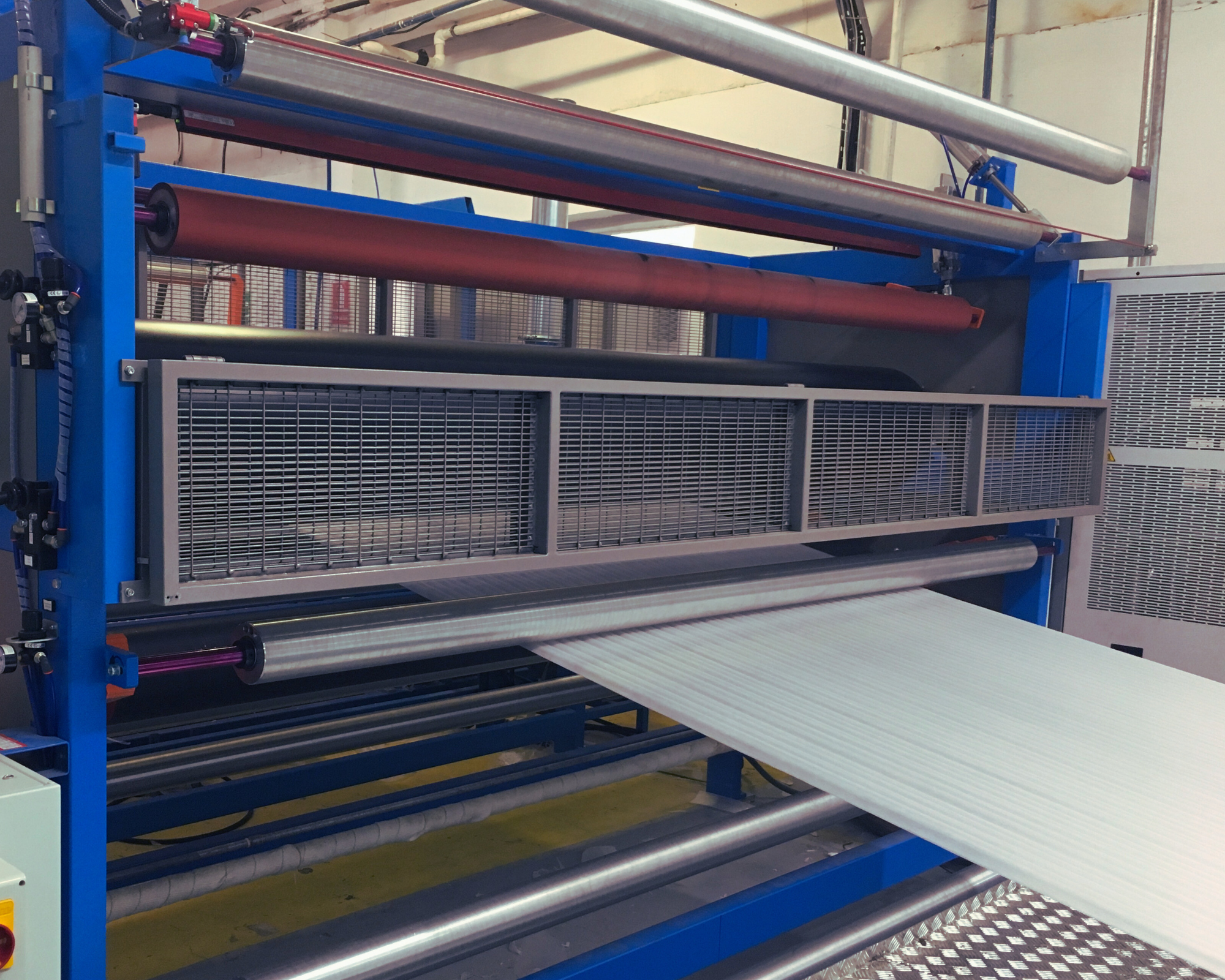

Our inline laminator is engineered to integrate directly into Your Extrusion Line. It’s ideal for processing foam (expanded film) and air bubble film, applying a HDPE or LDPE layer via a hot roll lamination system — all at high production speeds.

Whether you’re working with foam or plastic film, this machine becomes a seamless part of your workflow right after the extruder.

We listen first, then build. Every project is developed together with the client.

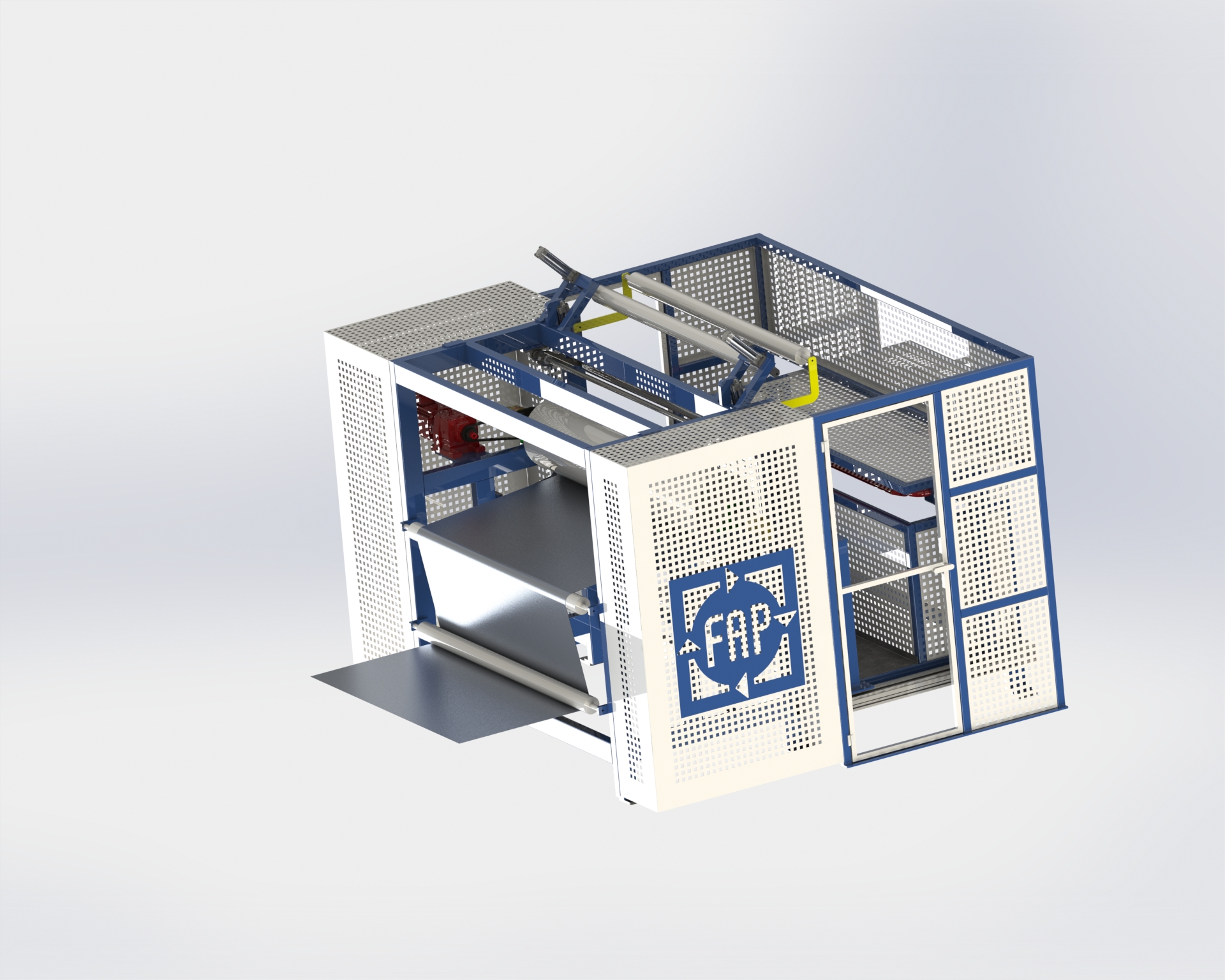

We don’t sell one-size-fits-all machines. Each laminator is custom-built to match your exact production needs.

We collaborate closely with every customer to design a modular solution that aligns with the material, speed, and final application of your production line.

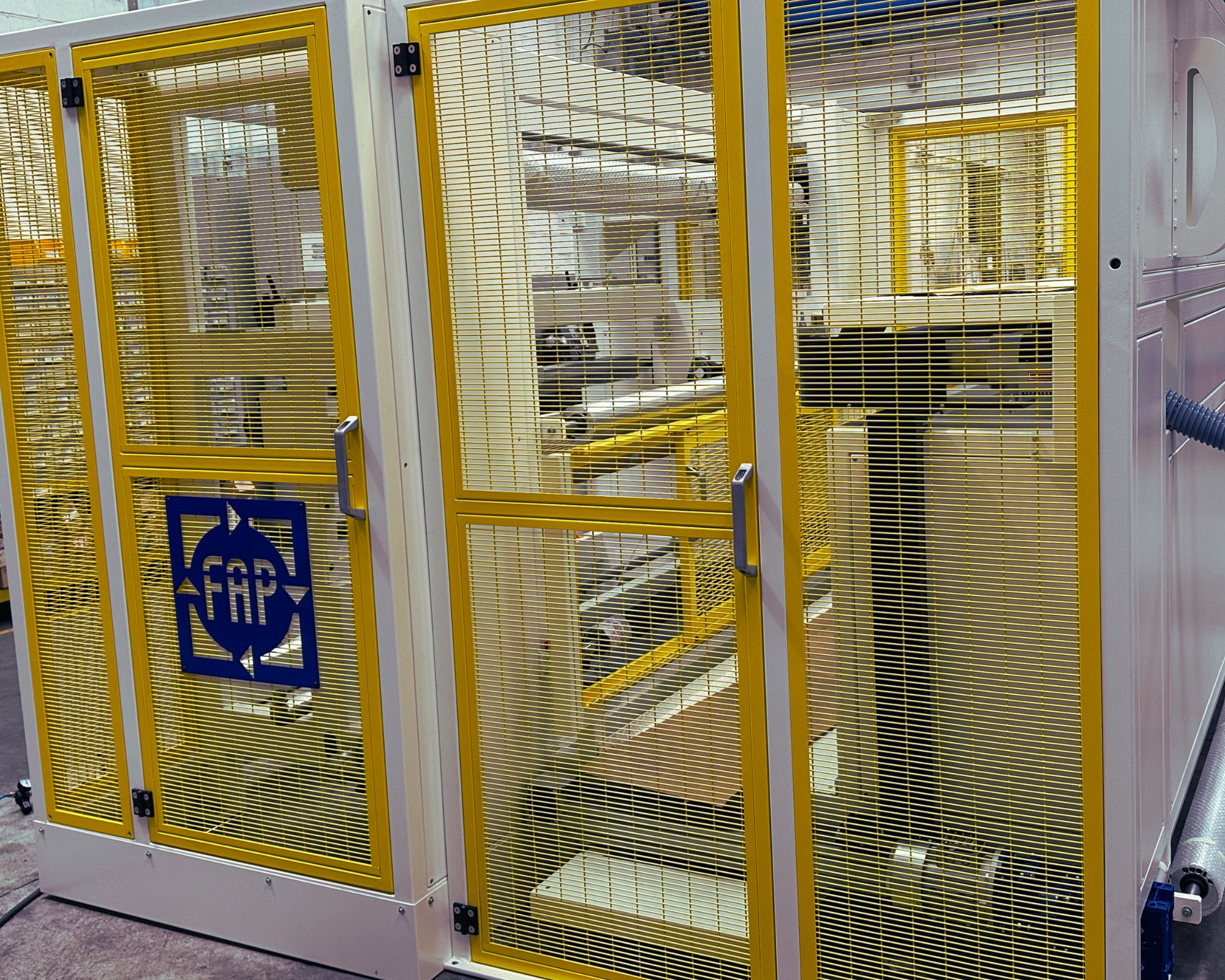

🔧 Tailored Integration – All our laminators are custom-designed to match your process.

⚙️ Modular Design – The system is built as a plug-in module that fits easily into any extrusion line.

⚡ High-Speed Performance – without compromising lamination quality.

🧩 Versatile Compatibility – Suitable for foam, air bubble film, and other plastic materials.

🔥 Proven Hot Roll Technology – Ensures consistent bonding with minimal material stress.

📦 Laminated materials are a go-to solution in protective packaging, particularly for e-commerce, electronics, furniture, and automotive components. They help protect goods from:

Foam and bubble films can be laminated and converted into: