Some thoughts on this hot topic or why is it right now necessary to switch from foamed polystyrene (EPS) to foamed polypropylene (EPP) in food packaging?

Extruded polystyrene (EPS) foam is today the main and cheapest type of foam polymer from which most single-use food containers and trays, coffee cups and egg containers are made.

So why are there more and more companies choosing the production of expanded polypropylene (EPP) in recent years? There are many debates, discussions and articles on this topic, and in some countries the use of extruded polystyrene foam in food packaging is already completely prohibited by law or is going to be soon.

So why is such “special” attention paid to polystyrene?

Modern technologies make possible to recycle and reuse both polypropylene and polystyrene, but there is always a "BUT".

And here are some of notes about the properties of EPS foams:

- The extruded polystyrene is a very crystalline and brittle material that breaks and crumbles quite a lot. It is torn apart by equipment and carried away by the wind. It also compresses very poorly and therefore takes up a lot of space in landfills. The process of recycling polystyrene is rather expensive and also its volume significantly increases the cost of logistics to processing centers. According to research, most of the plastic waste in the European Union (about 62%*) is not recycled, but simply ends up in landfills

- Moreover, when polystyrene foam is recycled, the original monomer styrene accumulates, which has carcinogenic properties.

- When processing expanded polystyrene, due to the frequent addition of a chemical blowing agent and an impact strength modifier to the original product, the melt viscosity is reduced, which limits the percentage of reuse of recycled polystyrene foam in production to a maximum of 40%.

Instead, the use of recycled polypropylene foam (EPP) allows up to 90% of it to be reused in the formulation.

The use of recycled polystyrene, as opposed to recycled polypropylene, is much more limited. Recycled polypropylene can be used in many industries, from injection molding to polypropylene filament production with varying percentages depending on the industry.

EPS foam is significantly inferior to EPP foam in terms of resistance to high temperatures. Thus, disposable tableware made of EPP foam can be used at temperatures up to 120-130 °C, and tableware made of EPS foam cannot be used at temperatures above 80-90 °C.

If we look at the statistics of the total volume of plastic waste recycling, polystyrene recycling takes up on average 9% of the total volume of recycled waste of this type of raw material, and the share of polypropylene recycling in the total volume of its disposal to landfill is on average 17%.

In addition, due to the more costly sorting process, more expensive logistics to recycling centers and the peculiarities of processing this type of waste, more and more factories are refusing to process expanded polystyrene.

This is pushing governments around the world to ban the use of extruded polystyrene in the food industry. Even though it is a single use, food container in EPP is not going to be banned and it will be a valid and safe alternative and totally recyclable solution worlwide.

It is the right time to change and we have a solution!

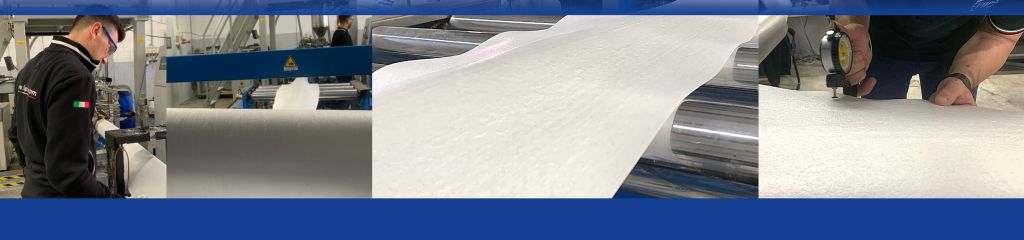

FAP is a manufacturer of advanced twin-screw PP foam extrusion lines using as a foaming agent hydrocarbon gases such as butane or carbon dioxide (CO2) .

Our ITALIAN FOAM CENTRE, together with polyolefin manufacturers and partners, is working to find opportunities and give new and improved physical and mechanical characteristics to polypropylene foam, making this product even more environmentally friendly and accessible to the market.