The Gas Injector is an essential component in the extrusion process for foam materials, including Polyethylene (EPE), Polypropylene (EPP), and Polystyrene (EPS). It introduces blowing agents such as CO₂, butane, isobutane, or nitrogen into the molten polymer to create a uniform cellular structure. By generating the necessary high pressure and ensuring optimal gas distribution within the melt, the gas injector enhances the nucleation process, resulting in lightweight foam with excellent insulating properties.

The precision and reliability of the gas injector directly impact the quality of foam produced. Accurate gas flow control guarantees a consistent nucleation process, which influences the mechanical strength and thermal insulation characteristics of the final product.

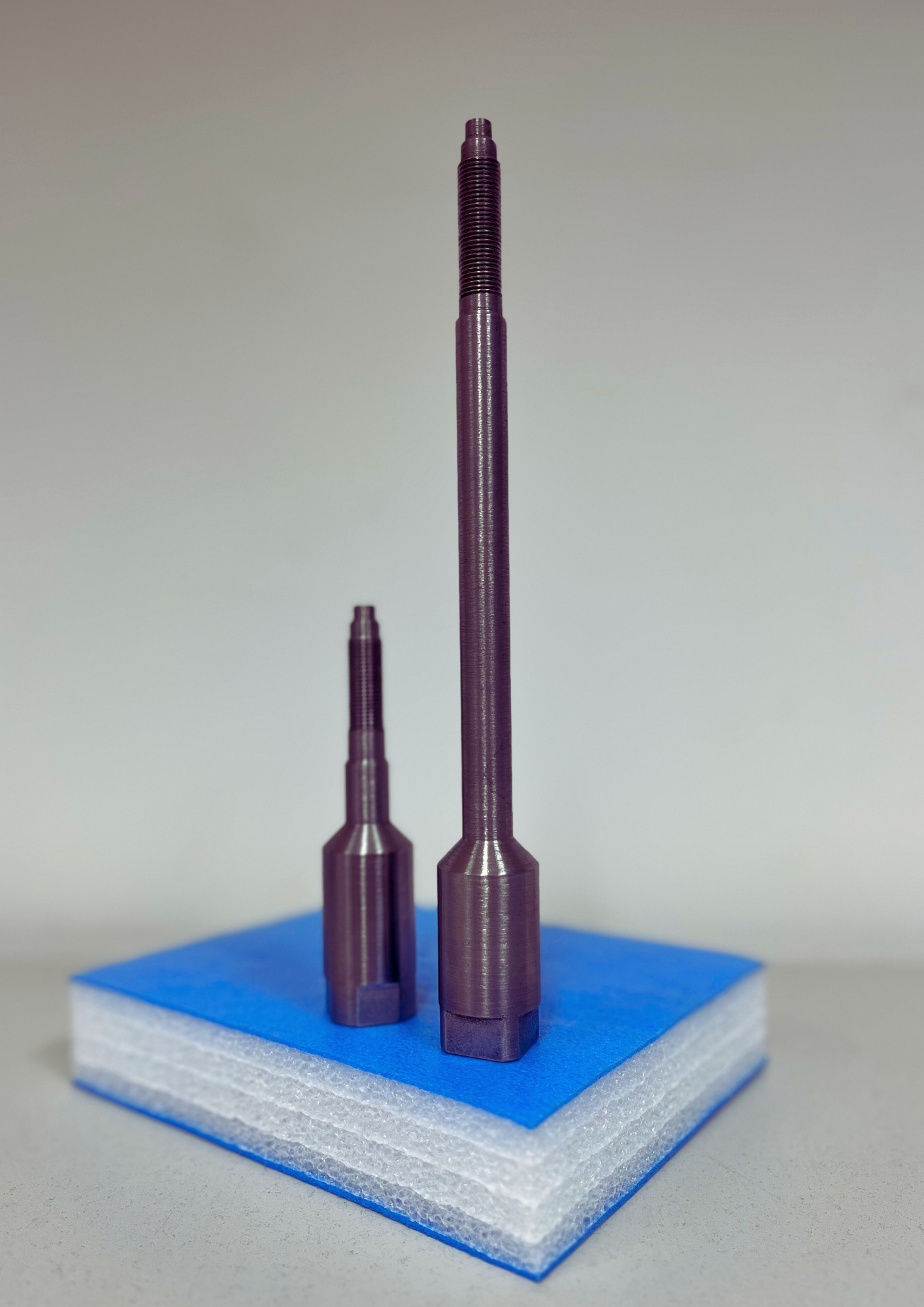

Each FAP Gas Injector is engineered for consistent and reliable gas flow, supporting efficient production and delivering high-quality foam materials. Our gas injectors are designed to maximize performance, precision, and durability, ensuring long operational life and flawless performance even in the most demanding extrusion environments.

Reliability: Flawless performance under demanding conditions.

Precision: Accurate gas flow control for uniform cellular structures.

Durability: Robust design for long operational life.

Polyethylene (EPE) Foam Extrusion

Polypropylene (EPP) Foam Extrusion

Polystyrene (EPS) Foam Extrusion

Choose FAP Gas Injectors for superior precision, reliable performance, and high-efficiency foam production.

Contact us today to learn how our solutions can enhance your extrusion line.