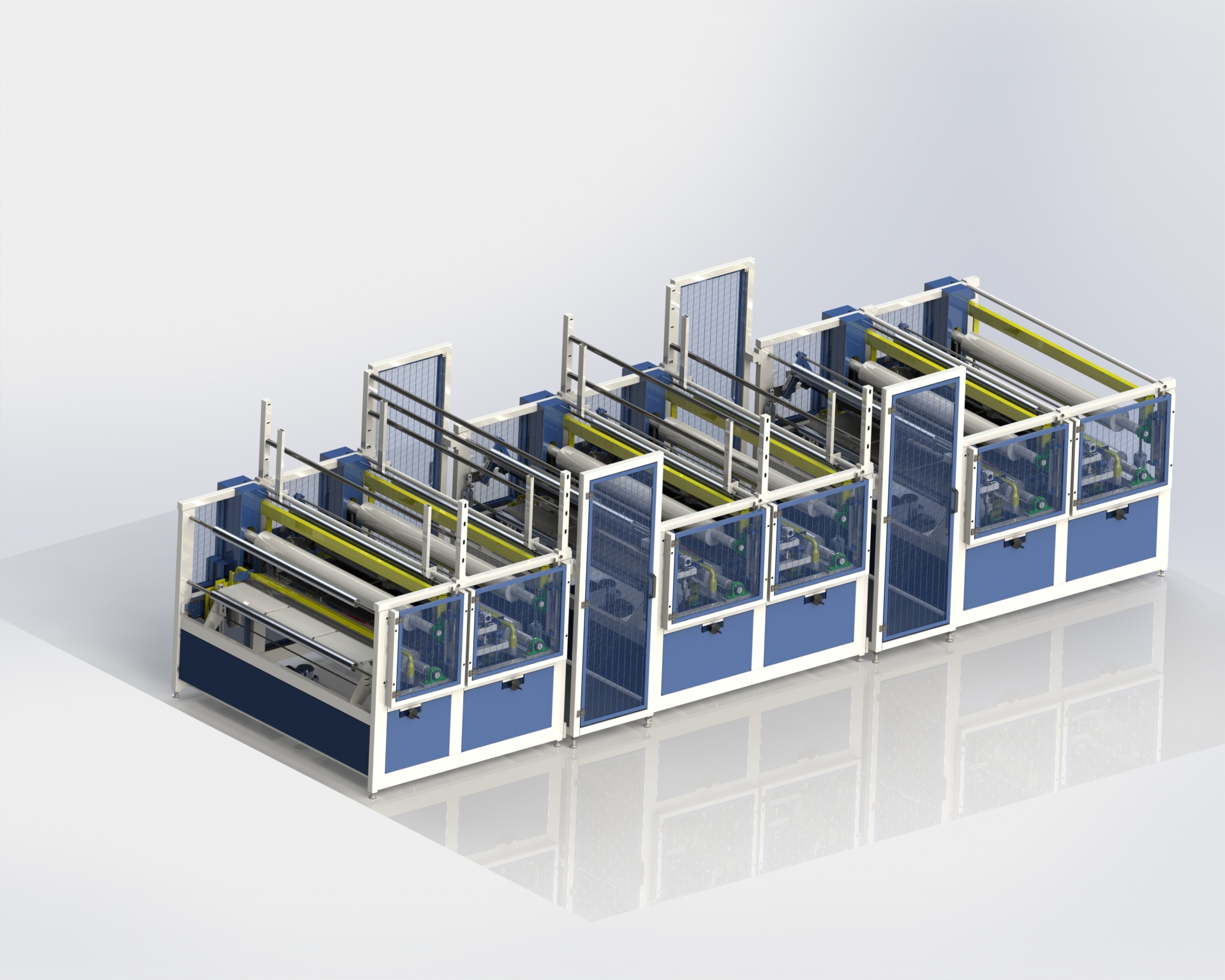

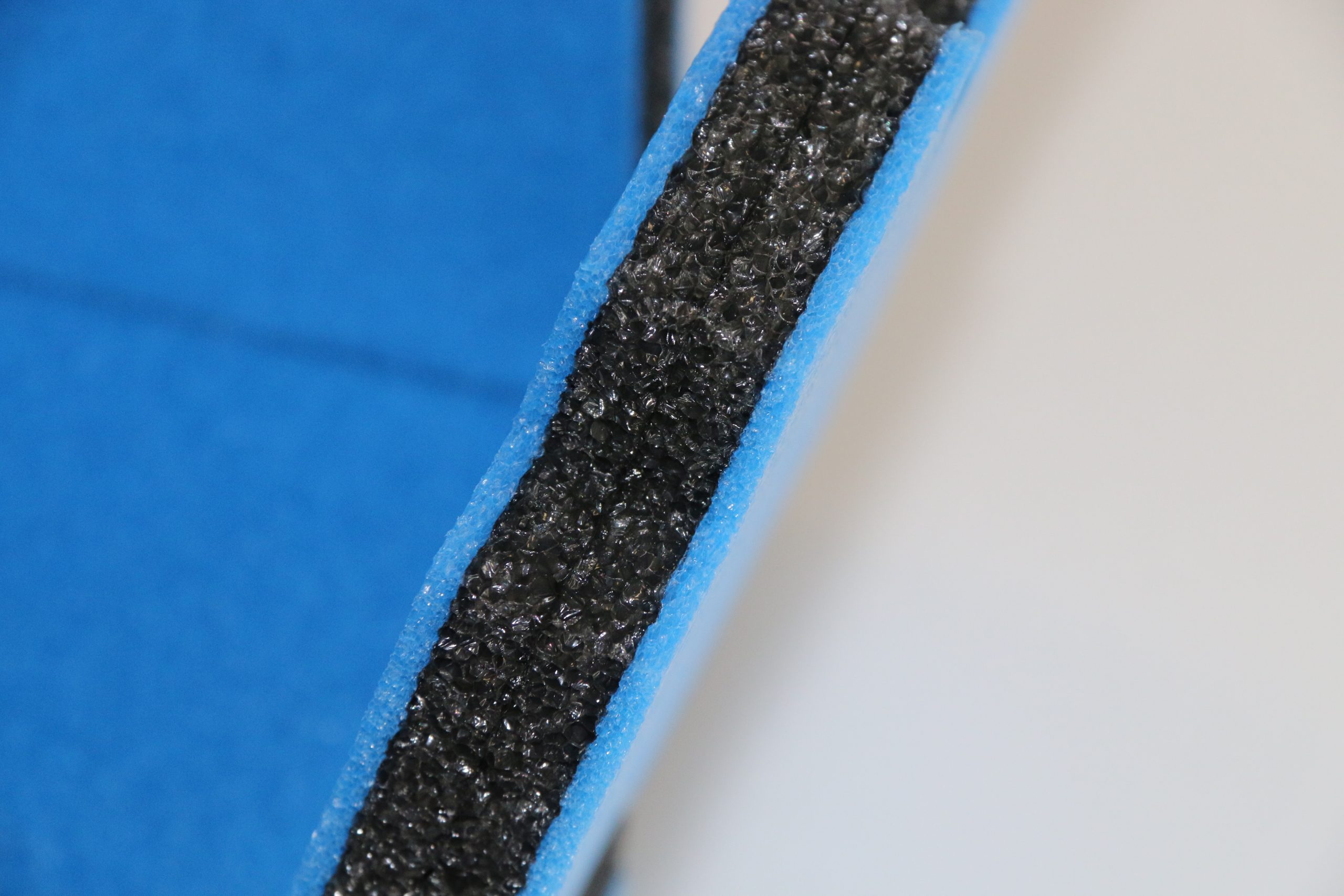

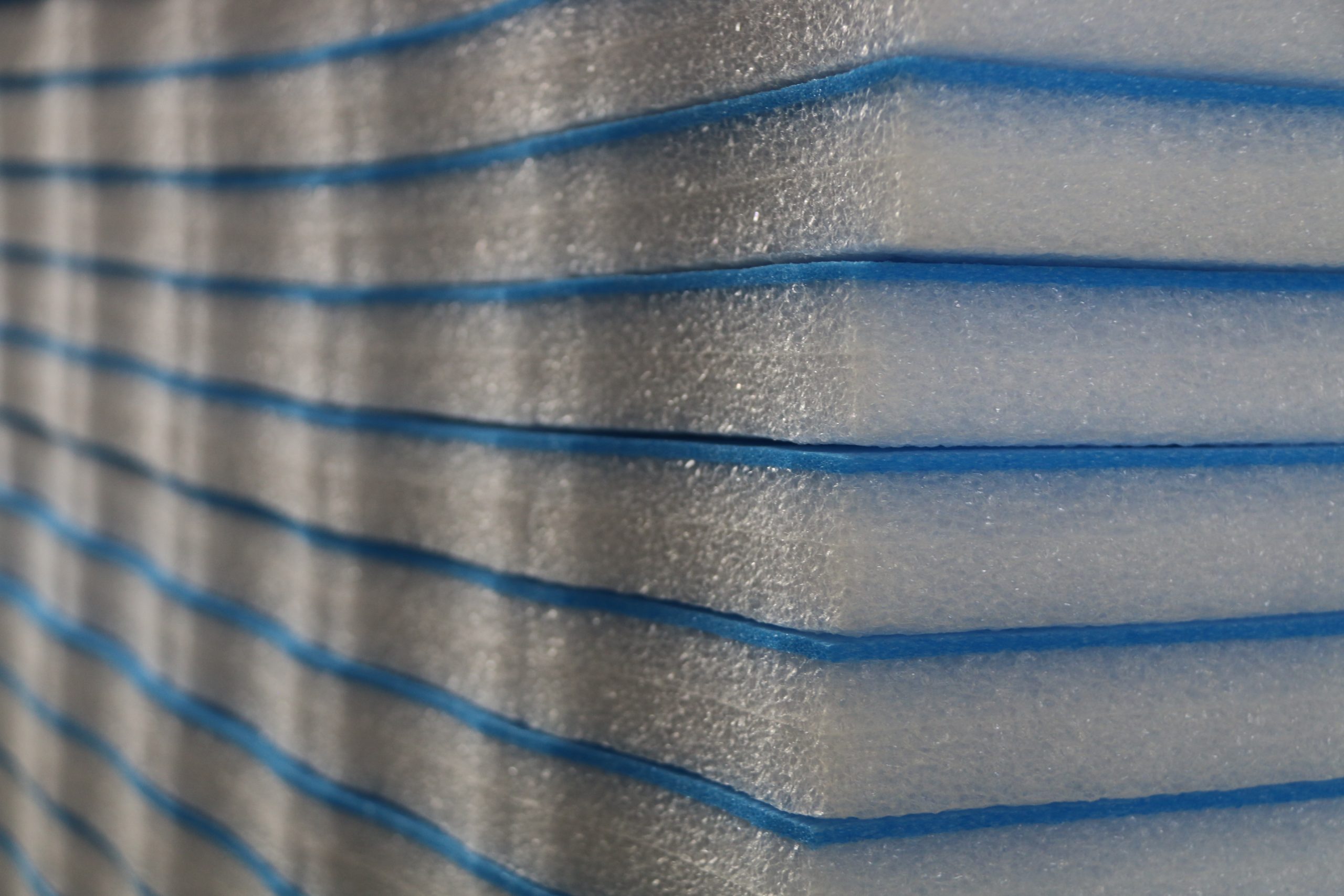

Complete highly efficient Multilayer Laminator for simultaneous lamination by HOT AIR (air blade) of multiple layers of high thickness polyethylene (PE ) and polypropylene (PP) foam of various densities for production of planks. This systems guarantees perfect adhesion of all numerous laminated layers. As a result, laminated foam planks are strong, resilient and elastic.

This laminator initially designed years ago, has undergone some advancements in recent years. While retaining its hallmark of high-quality production, we've upgraded its components and automation features to meet the evolving needs of modern manufacturing.

Latest technology for perfect lamination of high thickness foam layers in one step.

Each lamination line is tailored to meet the unique requirments of our clients. The lamination heads determine the composition of the machine and on which the total number of material layers (2 to 6) depends. The laminator is completed with unwinder units and Special Foam Cutter at the end of the line is included in this structure.

📦 𝘐𝘯 𝘵𝘦𝘤𝘩𝘯𝘪𝘤𝘢𝘭 𝘱𝘢𝘤𝘬𝘢𝘨𝘪𝘯𝘨: its shock and vibration damping properties guarantee the perfect solution for a variety of industrial products. The layered foam materials can be subsequently transformed into various customized shapes for packaging and transportation purposes.

🏡 𝘐𝘯 𝘵𝘩𝘦 𝘤𝘰𝘯𝘴𝘵𝘳𝘶𝘤𝘵𝘪𝘰𝘯 𝘪𝘯𝘥𝘶𝘴𝘵𝘳𝘺: foam boards with layers of different densities have proved their worth as an excellent heat, sound and hydro insulating product (insulation of hangars, cold storage warehouses, containers, internal walls, foundation and roofing of residential and industrial buildings, etc).

nr. 1 Double head for max. number of 3 layers

nr. 1 Double + nr. 1 Single heads for max. number of 4 layers

nr. 2 Double heads for max. number of 5 layers

nr. 2 Double + nr. 1 Single heads for max. number of 6 layers