An independent machine uniformly laminates foam or/and bubble air film of various thicknesses and densities with different types of materials.

Laminating process is a combination of 2 laminating systems:

Hot Air hearts in continues mode on the surface of both materials;

Hot Roll with an internal passage of hot oil transfer the heat on materials.

Non-stop Production system.

The machine can be upgraded by integrating some special equipment for continuous laminating process. Such equipment consists of: a foam ACCUMULATOR (up to 40 m of foam or bubble air film) and a JOINT SYSTEM to ensure the continuous production.

Latest technology for perfect lamination. Each laminating line is tailored to meet the unique requirements of our clients.

The laminator is completed with

📦 𝘐𝘯 𝘱𝘢𝘤𝘬𝘢𝘨𝘪𝘯𝘨: The reflective insulation sheets is a lightweight material for wrapping and dividing perishable or temperature sensitive items, protect the shipment from possible damage, while providing thermal value to help prevent spoilage of the shipment.

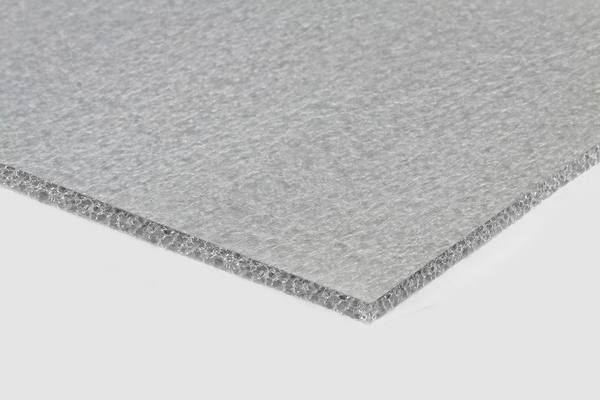

🏡 𝘐𝘯 𝘵𝘩𝘦 𝘤𝘰𝘯𝘴𝘵𝘳𝘶𝘤𝘵𝘪𝘰𝘯 𝘪𝘯𝘥𝘶𝘴𝘵𝘳𝘺: As a versatile insulation material for various applications: heavy-duty floor mat for excellent sound insulation and vapor barrier, universal sound and heat insulating material with a reflective effect (example: Polyethylene (PE) foam laminated with a metallized lavsan film), vibration-insulating material with a waterproofing layer (example: polypropylene (PP) foam laminated with waterproof polymer film).

Examples of lamination of different materials

Foam or Bubble Air Film + HDPE,

Foam or Bubble Air Film + LDPE,

Foam or Bubble Air Film + metallized film,

Foam or Bubble Air Film + paper + HDPE,

Foam or Bubble Air Film + aluminium film,

Foam or Bubble Air Film + aluminium film + LDPE,

Foam or Bubble Air Film + metallized lavsan film,

Foam or Bubble Air Film + waterproof polymer film