FAP understands the value of its clients' time, so instead of requiring a detailed project specification, FAP specialists are able to independently assess the project's "economics". Typically, a project's feasibility study is defined based on the following points:

- Obtaining data on the client's final product,

- Gathering data on the expected monthly production volumes,

- Estimating the complexity of the product and creating a preliminary sketch of the equipment needed for production,

- Estimating the maximum possible level of automation for the equipment based on the product's specifications,

- Calculating the necessary units and mechanisms,

- Estimating productivity per hour/month,

- Assessing the percentage of production facility utilization based on the expected production volumes,

- Providing a preliminary estimate of project costs.

This detailed project feasibility study allows our clients to avoid wasting resources and evaluate the project's effectiveness from the very beginning.

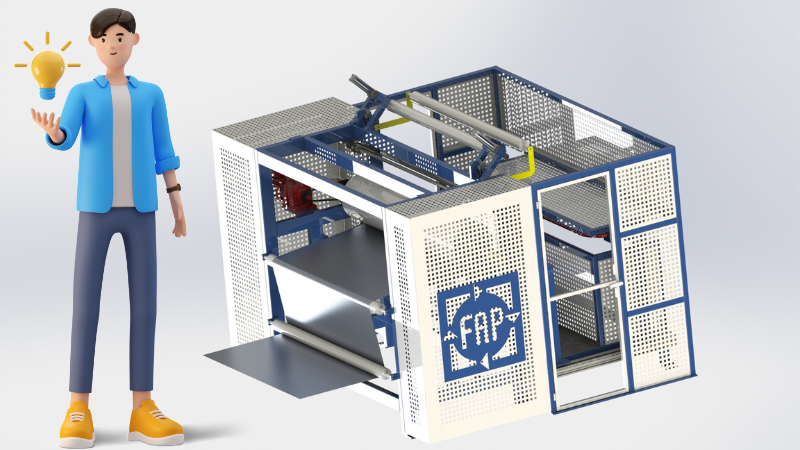

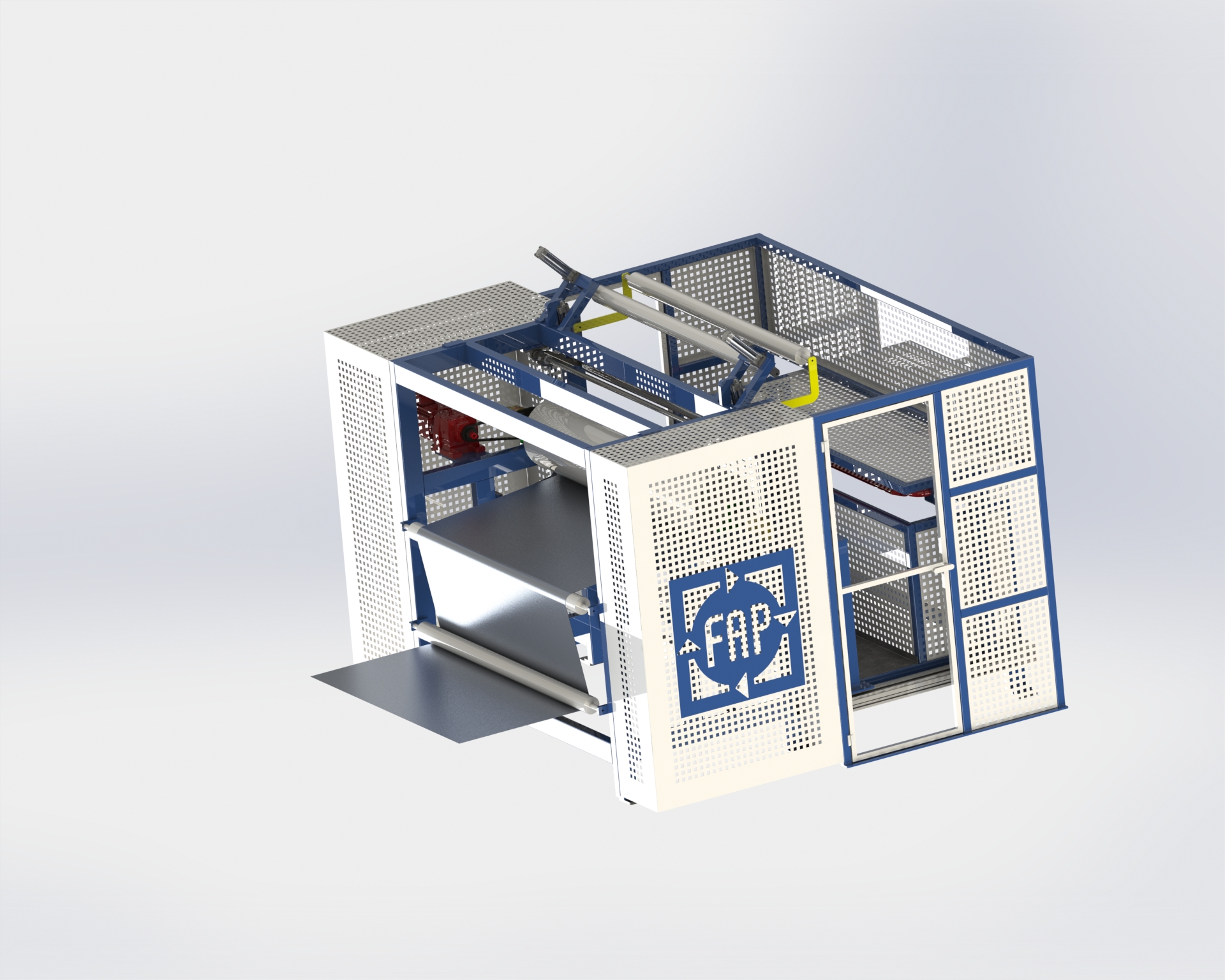

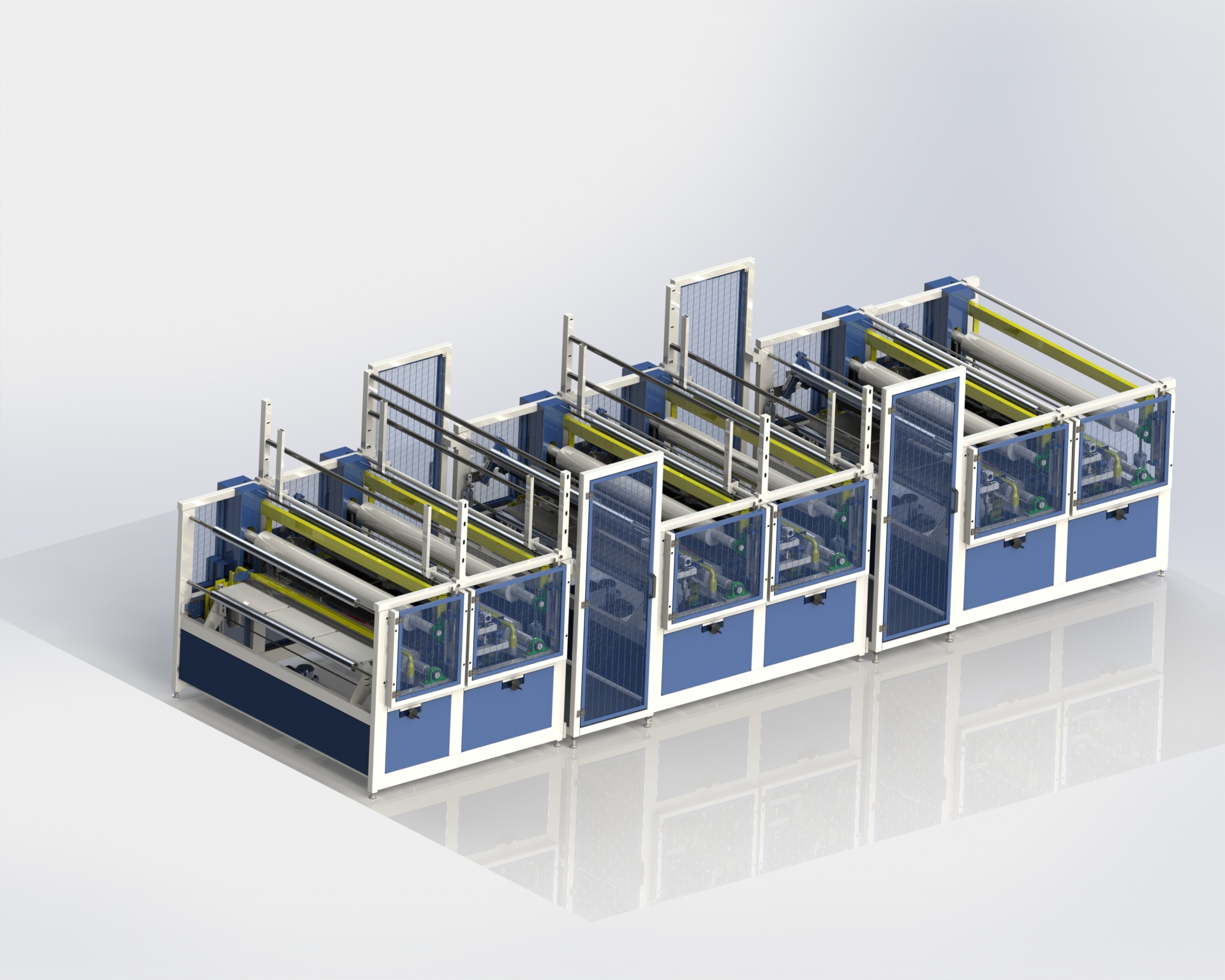

This step involves the creation of one or more drawings of the equipment and/or machinery to be designed by our design engineers in collaboration with the production engineer responsible for manufacturing processes. Thanks to our extensive practical experience in processing expanded polymers and other flexible materials, combined with modern computer modeling technology, the following tasks are addressed:

- Analysis and calculation of motorization for the required speeds and necessary installed power,

- Calculation of the necessary capacities for electrical and pneumatic components, and creation of preliminary electrical and pneumatic diagrams,

- Calculation of the overall weight of the equipment, energy consumption, air consumption, etc.,

- Computer modeling of each individual component and creation of a preliminary 3D/2D design,

- Compilation of a preliminary Bill of Materials (BOM).

At this step, the customer is presented with the project for the equipment and/or machinery, complete with all technical specifications.

The technical features, dimensions, weight, energy consumption, and any customer requests for modifications to the design are discussed. The cost of the equipment and/or machinery and the production conditions are presented. During this phase, the customer can accurately estimate the project cost down to the last cent and more precisely determine the project's payback period.

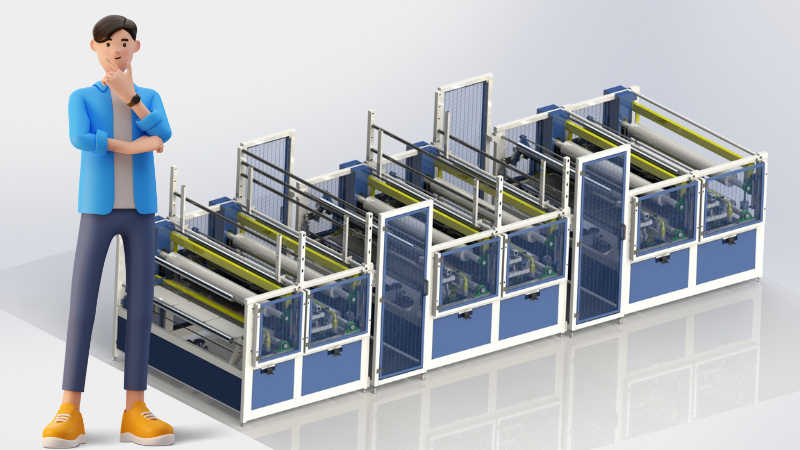

- Review of the project in its final version approved by the customer, creation of detailed construction drawings and assembly diagrams,

- Finalization of electrical and pneumatic diagrams,

- Review of the Bill of Materials (BOM) in its final version.

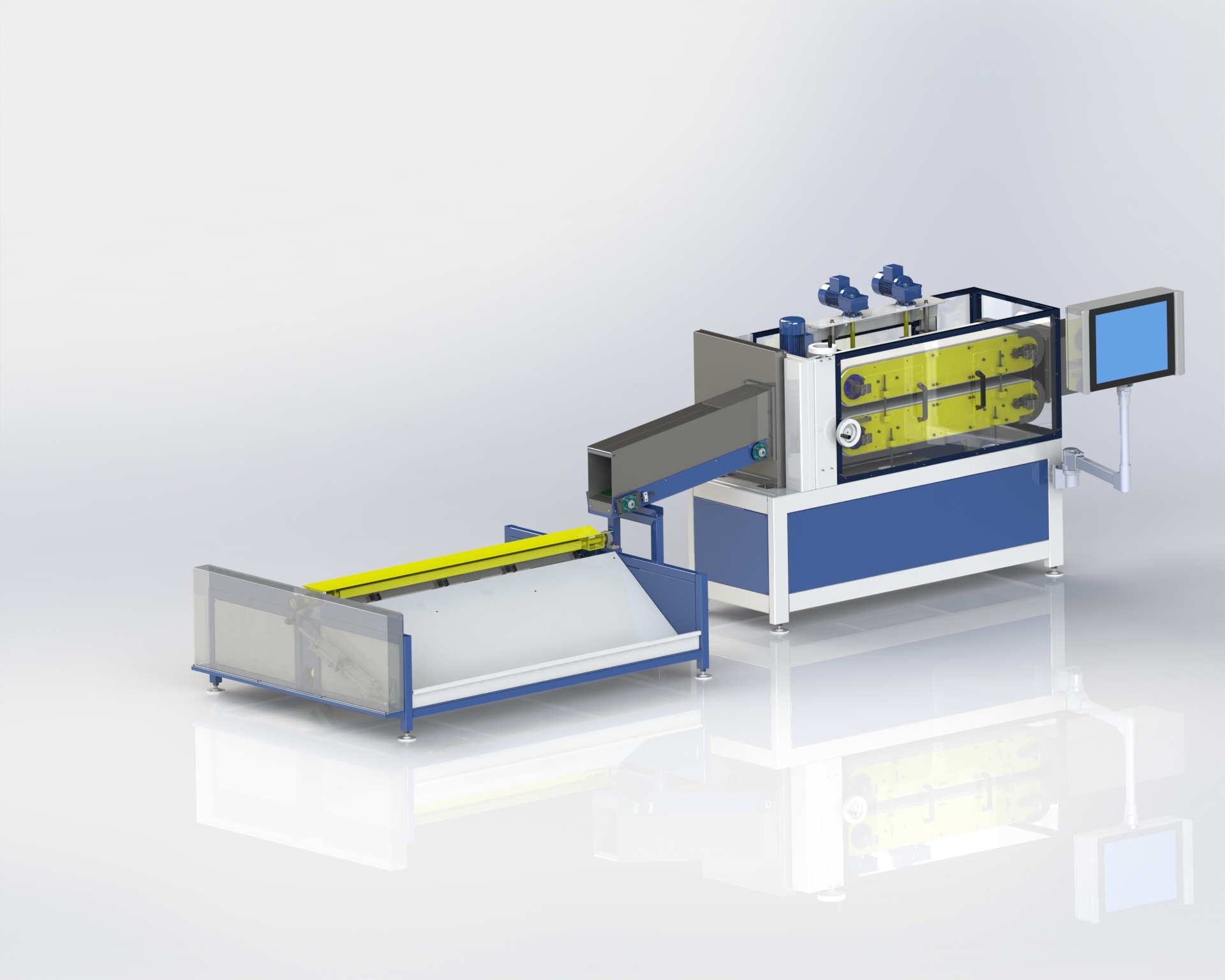

The construction of the equipment and/or machinery is carried out at FAP’s production facilities based on a construction schedule that has been agreed upon and approved with the customer.

Each external component supplied to FAP undergoes quality control upon arrival during the manufacturing process.

The construction schedule includes a description of each production phase with start and end dates, as well as delivery dates for external components. This allows the customer to continuously monitor the progress of the equipment and/or machinery construction.

Upon completion of construction, the equipment and/or machinery (if possible) is tested to determine its functionality and compliance with the approved specifications.

- The equipment/machinery is fully assembled at the FAP facility.

- The equipment/machinery is commissioned (if possible) and tested to ensure it meets the specified functions.

After testing (if possible), the equipment and/or machinery is packaged and shipped to the customer.

FAP provides full customer support, in particular:

- Installation at the customer's premises,

- Carrying out commissioning and adjustment work,

- Training of customer operators and technicians,

- Development of technological documentation, equipment maintenance regulations, standard operating procedures for the correct operation of the equipment and/or machinery.

...and we will help you turn it into reality.