How often do you analyze production losses associated with product quality, manufacturing defects and violations of foam polymer extrusion technology in general?

And how many potential markets and opportunities have been missed due to a lack of understanding of the technology for producing “non-standard” products?

Rhetorical questions that very often have no answers due to the lack of the most valuable resource, “TIME”.

Very often, production works on the principle of “solving the problem here and now” and frequent cases associated with shrinkage of the foam, destruction of cells and the formation of bubbles on the surface, delamination of the foam during the lamination process due to a violation of the “degassing” process and many other problems turn into this something “normal” and become simply “production costs”.

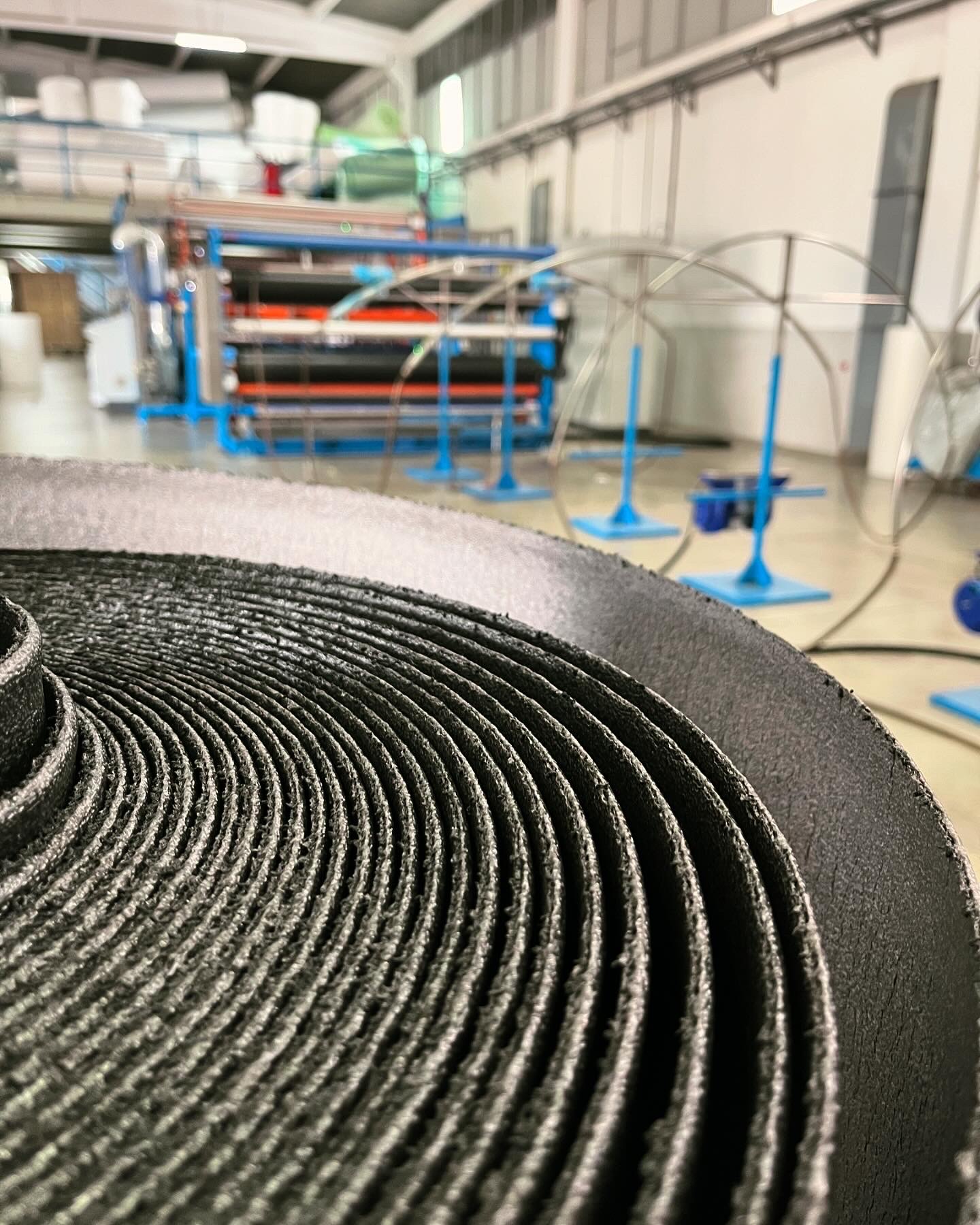

The production of physically foamed closed-cell polymers is a complex, but at the same time very logical science. Absolutely every technological process from creating a composition of materials, the required dosing volume, % gas solubility in the melt, foaming and crystallization to the process of “maturation” and degassing of the foamed polymer can be fully explained and standardized.

Analysis of the market need for the current product, which market areas can be covered by a new product made of non-crosslinked polyethylene & polypropylene foam;

Development of a raw material base and calculation of product costs based on the required physical and mechanical properties of finished products made of polyethylene & polypropylene foams;

Calculations of product productivity, optimal production batches and writing a roadmap for the production and storage of new products from polyethylene & polypropylene foams;

Launch of the product into mass production, training of engineering and production personnel;

Creation of technological documentation for product production and quality control measurement criteria.

Analysis of existing technological processes and product quality indicator;

Describing in detail production and technological processes, standard operating procedures, technological maps to minimize the risks of defects and reduce production losses.

Complete and detailed guide:

Let us support you and identify potential points of growth and development of your production!