The use of foamed polymers is extremely versatile, but the main thing is that all necessary technical requirements are met, specially in construction industry and as a striking example is a reflective insulation. Manufacturers of foamed polymers need to create materials that educate the final user, do not mislead him when choosing products for construction and repair, to force unscrupulous manufacturers to change their approach to production and product quality.

We all want to live in comfort and very often during construction or repair we install a “warm floor” system in our homes. Today, FAP would like to talk about the use of foamed polypropylene and polyethylene in this constructions.

What is reflective insulation for? How can a foam manufacturer not disappoint his customers? Can aluminium foil be used without a protective layer of transparent polymer in construction?

So, why is it necessary to use reflective insulation in the "warm floor" system everywhere and why is it rather dangerous to use foamed polypropylene or polyethylene without applying a reflective layer on it?

There are some reasons:

• Local overheating of the screed. As you know, the principle of operation of a "warm floor" system is quite simple. Heat from the heating element (water pipes or electric heaters) is transferred to the concrete screed, the concrete screed heats up and heats the coating on it.

It is the reflective layer of aluminum foil that contributes to the uniform heating of the screed and the floor covering, since the thermal conductivity of the foil is about 150-180 times higher than that of concrete and the foil heats up very quickly, evenly distributes heat over the entire space of concrete, without creating local overheating of the floor. The absence of aluminum foil as a reflective layer can cause that in some areas of the floor the heating element warms up much faster and absorb more heat, while in other areas there is no direct contact with the heating element. Ultimately, this can lead to cracking of the concrete screed.

• Reduced heat loss of the “warm floor” construction. PE or PP foam insulates the entire structure, preventing the heat goes down, since the coefficient of thermal conductivity of PE and PP foam with a thickness of 4-5 mm and a density of 25-30 kg/m3 is about 0.035 - 0.038 W/m2, which is approximately 1.5-2 times lower than that of concrete.

Many people mistakenly believe that it is the reflective foil that prevents the passage of heat down, acting as an insulator, but this is not correct. Unfortunately, even builders who have no idea about the principle of this action use only one aluminium foil as insulator without foamed polymer layer. As explained before, the thermal conductivity of aluminum foil is very high and it cannot be used as an insulator without having an air gap underneath, which is foam. Anyone who responsibly attended physics lessons at school has already understood that the foil fulfills exclusively the principle of convection and radiation.

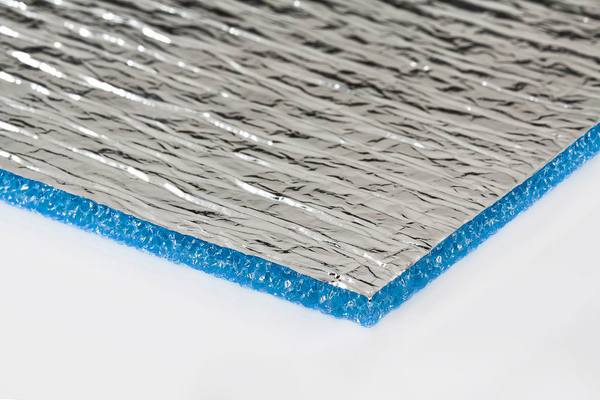

Thus, the use of PE & PP foam with a reflective foil layer with a thickness of only 25-30 microns will significantly increase the efficiency of the "warm floor" system, reduce the heating time of the concrete screed and reduce heat loss.

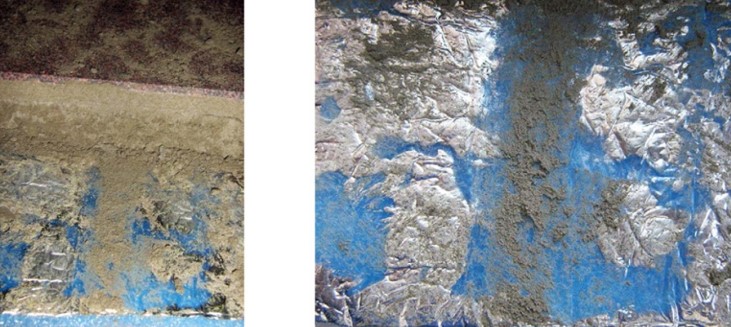

Is it possible to use foil on foamed polypropylene or polyethylene without a protective polymer layer in the "warm floor" system (reflective insulation) - the answer is NO!

The fact is that the reaction of an alkaline solution (cement) with aluminum leads to its destruction due to the displacement of hydrogen. After a while, the foil will simply dissolve and only the foamed polymer will remain. For this reason, there will no longer be a uniform distribution of heat over the concrete screed, which can lead to local overheating and cracks. Therefore, it is extremely important to use a foil with a protective polymer layer on the reflective side in the lamination of foamed polypropylene or polyethylene, since the protective polymer layer will not allow the reaction between the foil and the alkaline solution.