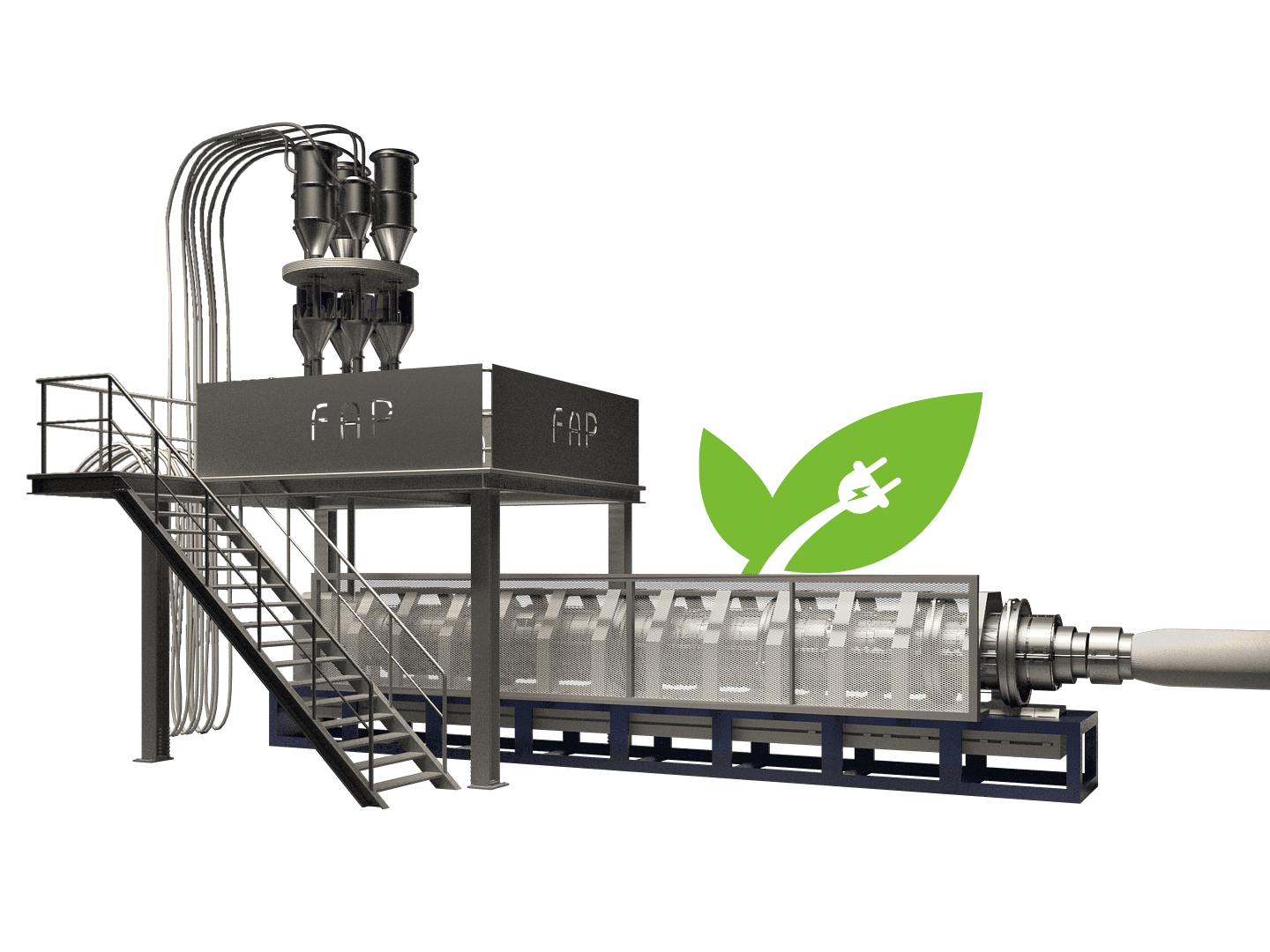

FAP’s foam machine is a twin-screw counter-rotating complete Extrusion Line for Polyethylene (PE) & Polypropylene (PP) Foam, robust and reliable, designed to work continuously, guaranteeing constant quality. The PE foam & PP foam machines are made adopting the most advanced technologies including the new high energy efficiency system; the processes are stable and easy to be run by the operators for 24-hour day 7/7, minimizing industrial waste.

Thanks to experience and high professionalism, FAP team offers complete "turnkey" project and services that include the design phase, assemblage and installation, start-up of machinery, staff training with know-how transfer.

Raw material

PE & PP pellets (granules)

Additives (GMS, talk, colour, modifiers, etc.)

Expansion agent

isobutane, propane, nitrogen, CO2

Production capacity

sheet: from 100 to 1200 kg/h

tube/profile: from 20 to 200 kg/h

Foam thickness / diameter

thicknesses: from 0,8 to 30 mm

internal diameters: from 10 to 180 mm

Foam width

from 600 to 3000mm

Foam density

from 15 to 400 kg/m3

Extrusion is the most commonly used foaming technology. It can be used to produce polyethylene (PE) and polypropylene (PP) foams of various densities. In the physical foaming process, hydrocarbons (such as isobutane or n-butane) are used to produce ultra-low and low-density foams. Inert gases, like supercritical nitrogen (N2) or carbon dioxide (CO2) are typically used to produce higher density foams of 100 - 150 kg/m3 or more.

The direct injection extrusion process transforms plastic PE or PP pellets into expanded film (non cross link with closed cell structure polyethylene or polypropylene foam, can be 100% recycled).

The exclusive and original designing of extrusion heads has been studied by FAP for excellent control of the material and its distribution inside before the exit.